Высокопрочная износостойкая композитная сварная Износостойкая стальная пластина

- Категория: Carbon Steel >>>

- Поставщик: Tianjin,Wodon,Wear,Resistant,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 305.35 $* | 320.23 $* |

| Aug-19-2025 | 302.55 $* | 317.30 $* |

| Jul-19-2025 | 253.50 $* | 266.78 $* |

| Jun-19-2025 | 297.67 $* | 312.50 $* |

| May-19-2025 | 259.37 $* | 272.53 $* |

| Apr-19-2025 | 292.35 $* | 307.58 $* |

| Mar-19-2025 | 289.19 $* | 303.37 $* |

| Feb-19-2025 | 287.10 $* | 301.21 $* |

| Jan-19-2025 | 284.21 $* | 298.5 $* |

Характеристики

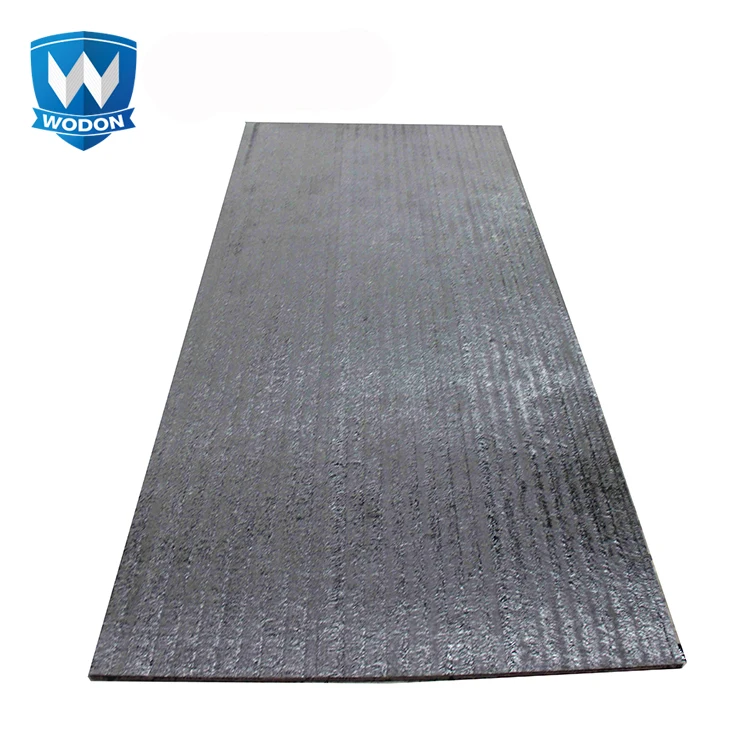

high hardness 58-63 HRC wear resistant composite welded wear steel plate

Wodon wear plates are manufactured by welding one or multiple wear resistant layers on a medium or low carbon steel base plate.

The overlay alloy has a high amount of chromium carbide hard particles which makes the plate have good wear and impact resistance.

Overlay thickness range: 3-25mm

Wear plate size: 1400*3000,1400*3400, 1400*3500, 2100*3500, customized.

Product Name | high hardness 58-63 HRC wear resistant composite welded wear steel plate |

Brand | Wodon. |

Base Plate | Q235/Q345. |

Hardfacing layer | High chromium high carbide overlay. |

Chemical Composition | C(%): 3.0-5.0 ,Cr(%): 25-40. |

Microstructure | The carbide (Cr7C3) volume fraction on the microstructure is above 50%. |

Hardness | HRC58-65. |

Surface Treatment | Hardfacing,clading,coated. |

Technique | Hardfacing,open arc welding,submerged arc welding. |

Wear Resistance | High wear resistance,30 times higher than low carbon steel and 12 times than heat treated steel. |

Impact Resistance | Medium. |

Flatness tolerance | ±3mm/m. |

Thickness tolerance | Uniform overlay thickness, with tolerance within 0-0.5mm. |

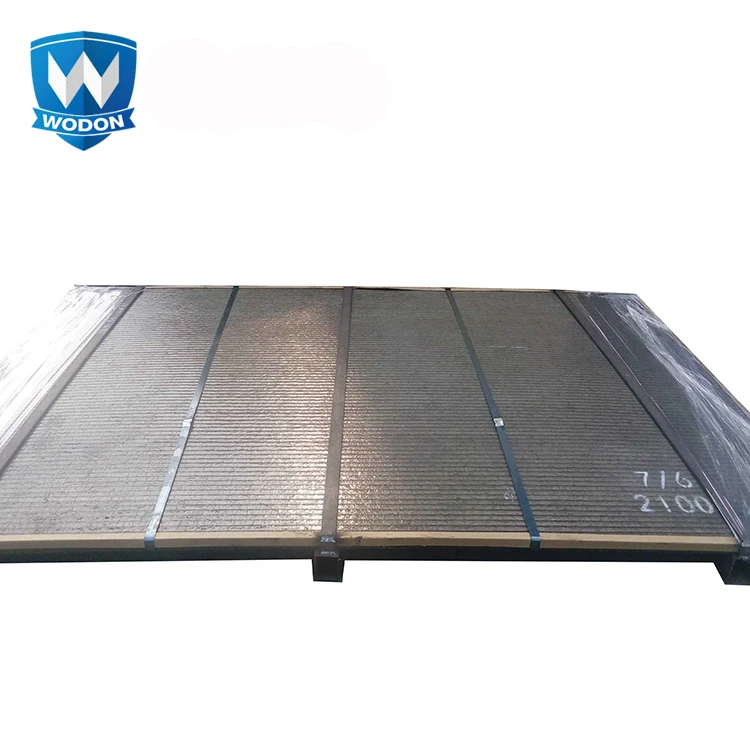

Main Thicknesses | 3+3,4+4, 5+5 6+4,6+5,6+6,6+8 8+4,8+5,8+6,8+7,8+8 10+4,10+5,10+6,10+7,10+8,10+9,10+10,10+20 12+4,12+5,12+6,12+7,12+8,12+10,12+11,12+12 14+6,14+8,14+10,16+6,16+8,16+10 18+6,18+8,18+10,20+5,20+6,20+8,20+10,20+20,30+10,40+10 Customized. |

Plate Size | Open arc welding wear plate:1400*3400mm Submerged arc welding wear plate:1400*3000mm, 1400*3500mm, 2100*3500mm. Customized. |

Place of Origin | China. |

Application | Mining,Steel,Cement,Power,Port,etc. |

Wodon wear plates are used to make many complex wear parts to be positioned in high wear places.

We have several equipment to transform our plates: six sets of plasma cutting machine , 4 bending machines and pressing machines,

with high processing capacity operated by engineers and technical experts, we can provide wear plate cutting, bending, bolting, punching and welding according to customer's drawings.

1.Drilling Holes

Straight holes and Countersunk holes.

2.Bolt embedded welding in the back

Embedding the Pre-processed bolt in the back of wear plate.

3.Bending

Wodon wear plate can be cold formed and made into curve or cone.

4.Welding

Wodon wear plate can be welded and assembled into kinds of wear parts.

Wear pipe, Elbow, Square to round transition

We also introduced in our factory automatic welding equipment for pipes (internal and external) meeting the increasing demand for small diameter wear pipes.

Wear pipes

1. Steel pipe with regular base material + overlay, pipes are welded with our automatic welding machine resulting in good shaped and flat surface pipes.

2. Bending the wear plate into round pipes

3. Assembling the wear plate into square pipes

Automatic welding, metallurgical bonding, available to weld the maximum pipe diameter of 80mm and maximum pipe length of 3000mm.

Wear elbow

Weld directly on the elbow wall

using wear plate to make lobster back bend

wear plate used to make tube

Quality Assurance: 25-40% high chrome content, carbide (Cr7C3) volume fraction above 50%, 58-65HRC, smooth surface, high wear resistance.

Professional: Many experienced surface engineering professionals, solid technical knowledge and R&D capacity.

OEM&ODM: Customized orders are available.

Certificates: ISO9001, OHSAS18001, ISO14001, ASTM G65 test report, third party test report, etc.

Tianjin Wodon Wear Resistant Material Co. Ltd is located in Tianjin city, China’s northern international shipping center. We are specialized in researching,

developing and producing wear resistant products with many years experience in this field. We have more than 200 employees, with an annual output of

90,000 m² of wear plates and 8,000 tons of welding consumables.

hardface wear plate workshop, open arc welding machine, bending machine, plasama cutting machine

Testing equipment :Carbon-sulfur Detector, Portable Rockwell Hardness Tester, Portable Spectrograph, Desktop Rockwell Hardness Tester, Wet Sand Rubber Wheel Wear Tester, Metallurgical Microscope, Thickness Tester, Metallographic Grinding and Polishing Machine, Powder Test Sieve.

welding wire warehouse, 150-250kgs welding wires packed in drum

wear plate warehouse and sample room

Customer on site visit and exhibitions

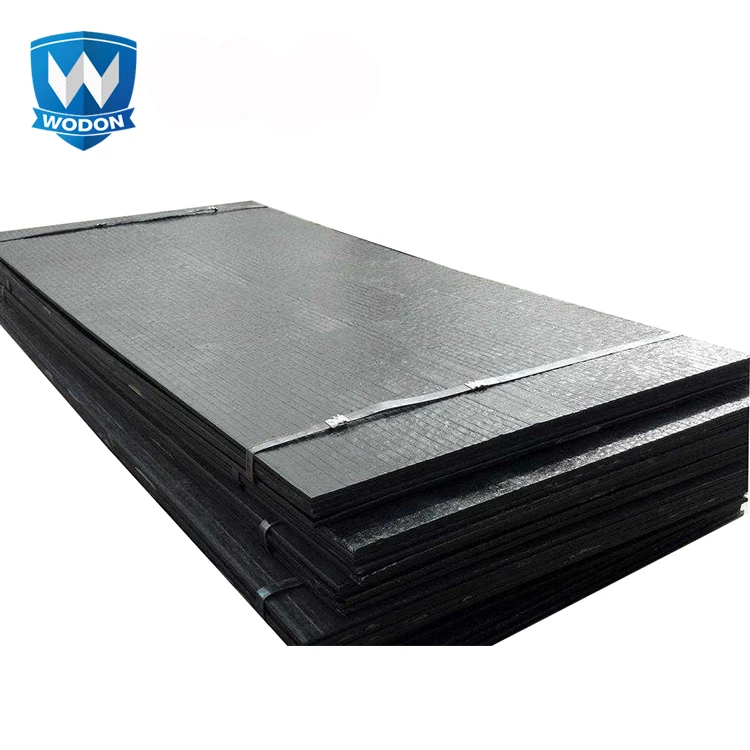

Packaging: Steel pallet, Non fumigation pallets,Customized

Packaging Size: 1.4*3.4, 1.4*.3.0, 1.4*3.5, 2.1*3.5, customized.

Delivery Detail: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

wear plate packaging

Our company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer’s probems.If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A:30% T/T in advance ,balance against copy of BL.

If you have another question, pls feel free to contact us as below: