Машина для подсчета нумерации автоматическая бумага фрикционных карт 0 02-5 мм двигатель предоставленный 70-100 шт/мин CE ISO 20 см 220

- Категория: Вспомогательное упаковочное оборудование >>>

- Поставщик: Xiamen,Peihong,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 893.54 $* | 938.82 $* |

| Aug-17-2025 | 885.11 $* | 929.72 $* |

| Jul-17-2025 | 743.29 $* | 780.86 $* |

| Jun-17-2025 | 870.79 $* | 914.98 $* |

| May-17-2025 | 758.70 $* | 796.36 $* |

| Apr-17-2025 | 855.51 $* | 898.81 $* |

| Mar-17-2025 | 848.23 $* | 890.46 $* |

| Feb-17-2025 | 840.63 $* | 882.23 $* |

| Jan-17-2025 | 833.73 $* | 875.21 $* |

Характеристики

Product Description

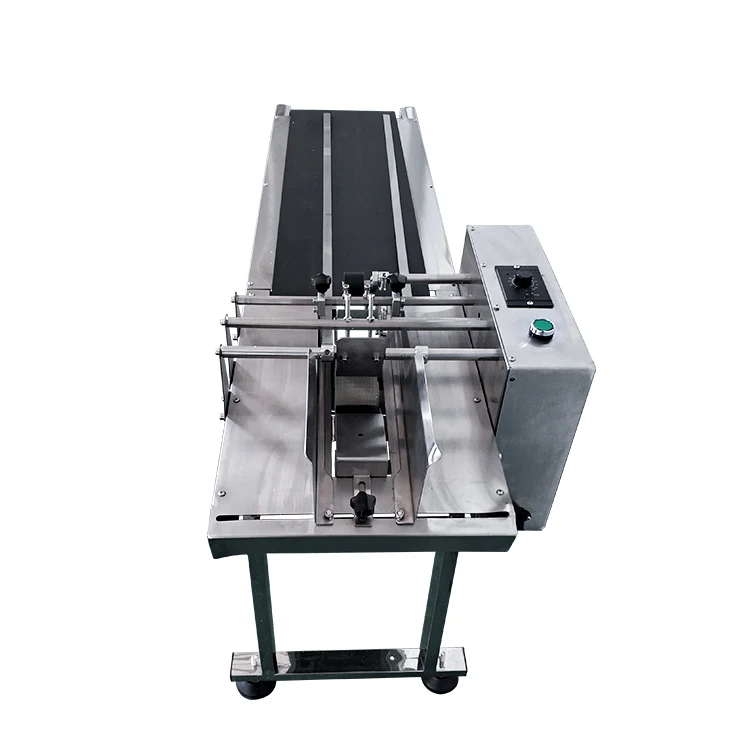

Brief introduction about friction type paging machine

This machine is mainly used for automatic paging of sheet products of various thicknesses and various materials, including scraps of paper, name card, label, cards of various materials, telephone card, IC card, IP card, game rechargeable card, plastic composite packaging bag, paper box pieces, paper bag, etc. It can separate a pad of sheet products into independent pieces, and convey them by the belt, thus to let the ink jet machine to spray code piece by piece or for other uses. Photo sensor may be installed to count products. And it can also be set to shut down when certain quantity is reached.

This machine is mainly used for automatic paging of sheet products of various thicknesses and various materials, including scraps of paper, name card, label, cards of various materials, telephone card, IC card, IP card, game rechargeable card, plastic composite packaging bag, paper box pieces, paper bag, etc. It can separate a pad of sheet products into independent pieces, and convey them by the belt, thus to let the ink jet machine to spray code piece by piece or for other uses. Photo sensor may be installed to count products. And it can also be set to shut down when certain quantity is reached.

Operation

Instruction about operation

Please read through this instruction before using this machine, and connect to power supply;

*For the first time of operation, it shall basically operate as the following steps*

1. Connect the power cable to single-phase power supply (it is required to have good earth wire);

2. Press down the general power supply switch on the operating panel, and then the inverter high lights;

3. Adjust paging width:

Please read through this instruction before using this machine, and connect to power supply;

*For the first time of operation, it shall basically operate as the following steps*

1. Connect the power cable to single-phase power supply (it is required to have good earth wire);

2. Press down the general power supply switch on the operating panel, and then the inverter high lights;

3. Adjust paging width:

Adjust the space between the left and the right guide pieces according to the width of the product for paging. The space shall be 0.5-1mm wider than the product; And then, the center of the product shall be aligned to the center of the guide belt, then, screw down the bolts of the front and the back guide pieces.

4. Put product in:

Put a pad of product for paging (guarantee to have no adhesion phenomenon) onto paging assistant platebetween the left and the right guide pieces (or the enlarged supporting board or widened supporting board), and make it as slope inclined backwards and push it into baffle plate position.

5. Paging pressure adjustment:

In order to make the products be output piece by piece successfully without overlapping or blocking, it needs to adjust the interval and pressure between the pressing leather and the paging belt. If the interval has been well adjusted at the time when it is out of factory, the adjustment to this interval can be omitted.

If the products are of overlapping pieces or blocking of output or inclined paging due to differences in material and specification, it needs to re-adjust. The screw on the pressing roller of the green pressing board shall be adjusted to make it able to increase or decrease the press on pressing roller in balance, and transfer to green pressing board, thus to solve the problem of overlapped paging or output blocking or inclined paging; for overlapped paging, it needs to increase press of adjusting screw on the pressing roller; for output blocking, it needs to decrease the press of the left and right roller screws on the pressing roller. For inclined paging, it may be because of the inclined left and right guide pieces, please adjust the left and the right guide pieces.

6. Run/Stop:

Connect to power supply and press the green button, then the lamp will turn on; screw off the red emergency stop button, and rotate the black button of the inverter along clockwise direction to adjust frequency. Then the conveying belt, guide belt, and paging belt would rotate to perform automatic paging. If you need to pause paging or no product is put in, please press red stop switch to shut down the machine, in order to avoid long term friction between pressing leather and the paging belt for it may cause abrasion. Therefore, please try to put materials in continuously while

paging, or else, please shut down the machine if no product would be put in.

7. Speed adjustment:

In order to perform paging for the products successfully, the inverter can be adjusted to regulate the speed of the whole machine, thus to reach the best effect; The speed can be accelerated or decelerated by rotating the black knob on the inverter. And the displayed frequency value would be increased or decreased accordingly.

8. Function of counter:

4. Put product in:

Put a pad of product for paging (guarantee to have no adhesion phenomenon) onto paging assistant platebetween the left and the right guide pieces (or the enlarged supporting board or widened supporting board), and make it as slope inclined backwards and push it into baffle plate position.

5. Paging pressure adjustment:

In order to make the products be output piece by piece successfully without overlapping or blocking, it needs to adjust the interval and pressure between the pressing leather and the paging belt. If the interval has been well adjusted at the time when it is out of factory, the adjustment to this interval can be omitted.

If the products are of overlapping pieces or blocking of output or inclined paging due to differences in material and specification, it needs to re-adjust. The screw on the pressing roller of the green pressing board shall be adjusted to make it able to increase or decrease the press on pressing roller in balance, and transfer to green pressing board, thus to solve the problem of overlapped paging or output blocking or inclined paging; for overlapped paging, it needs to increase press of adjusting screw on the pressing roller; for output blocking, it needs to decrease the press of the left and right roller screws on the pressing roller. For inclined paging, it may be because of the inclined left and right guide pieces, please adjust the left and the right guide pieces.

6. Run/Stop:

Connect to power supply and press the green button, then the lamp will turn on; screw off the red emergency stop button, and rotate the black button of the inverter along clockwise direction to adjust frequency. Then the conveying belt, guide belt, and paging belt would rotate to perform automatic paging. If you need to pause paging or no product is put in, please press red stop switch to shut down the machine, in order to avoid long term friction between pressing leather and the paging belt for it may cause abrasion. Therefore, please try to put materials in continuously while

paging, or else, please shut down the machine if no product would be put in.

7. Speed adjustment:

In order to perform paging for the products successfully, the inverter can be adjusted to regulate the speed of the whole machine, thus to reach the best effect; The speed can be accelerated or decelerated by rotating the black knob on the inverter. And the displayed frequency value would be increased or decreased accordingly.

8. Function of counter:

This is the function we add according to the user’s requirement. It needs to propose to us at the time of placing order for the machine. The standard configuration excludes this

9. Shutdown:

At the time of shutdown, please press the red stop switch firstly, and then press the green power supply switch, and finally pull out the plug. The sequence for starting machine is right reversed.

9. Shutdown:

At the time of shutdown, please press the red stop switch firstly, and then press the green power supply switch, and finally pull out the plug. The sequence for starting machine is right reversed.

Product Paramenters

Size of Separated Items | 40-320mm |

Width | 60-300mm |

Thickness of items being paged | 0.08-5mm |

Power Supply | 220V |

Power | 180W |

Smart count function | Yes |

Speed adjustment mode | Stepless frequency speed adjustment |

Size | 1350*340*770mm |

Remark | Standard |

Notes

1.ugh this page carefully before using the machine;

2. Before connecting to power supply, the machine shall be checked to have power supply switch at [off] status. And then, please operate according to the steps instructed on this usermanual;

3. In case that the machine would be stopped and not used for a long time, please clean it with dry cloth. Do not use corrosive cleanser while cleaning;

4. It is forbidden to splash fluid into inner part of machine electric cabinet for it may corrode or result in short-circuit of internal electrical elements;

5. Please check the appearance of the machine to guarantee no deformation, damage or rust, and all axles shall be able to rotate flexibly without blocking;

6. This machine is designed as single-phase AC 220V; power line is of 3-line flat plug, which shall be connected to 3-pin socket with earth wire.

2. Before connecting to power supply, the machine shall be checked to have power supply switch at [off] status. And then, please operate according to the steps instructed on this usermanual;

3. In case that the machine would be stopped and not used for a long time, please clean it with dry cloth. Do not use corrosive cleanser while cleaning;

4. It is forbidden to splash fluid into inner part of machine electric cabinet for it may corrode or result in short-circuit of internal electrical elements;

5. Please check the appearance of the machine to guarantee no deformation, damage or rust, and all axles shall be able to rotate flexibly without blocking;

6. This machine is designed as single-phase AC 220V; power line is of 3-line flat plug, which shall be connected to 3-pin socket with earth wire.

Please note that, it shall not be connected to 380V power supply, or else, the machine would be burnt.

7. Conveying speed range: 20~50HZ; too slow speed can easily result in motor heat and damage;

8. For the parameters of the inverter of this machine, all, except the motor speed(frequency), shall not be adjusted by yourself, for it may be hard to reset and the machine may not run

9. Please do not start motor if no article is put on the machine for paging, thus to avoid long time friction between the pressing leather and the paging belt which may shorten the service life of the machine.

7. Conveying speed range: 20~50HZ; too slow speed can easily result in motor heat and damage;

8. For the parameters of the inverter of this machine, all, except the motor speed(frequency), shall not be adjusted by yourself, for it may be hard to reset and the machine may not run

9. Please do not start motor if no article is put on the machine for paging, thus to avoid long time friction between the pressing leather and the paging belt which may shorten the service life of the machine.

Recommend Products

Company Profile

Troubleshooting

1. Power supply indicating lamp doesn’t turn on: check the source of power supply and the fuse inside the power supply socket. The fuse shall be 10A/220V. And check whether the power supply button is pressed.

2.Abrasion of guide belt and paging belt: the machine shall be shut down when no product is put on, thus to reduce abrasion. For normal abrasion, please change the guide belt and paging belt: screw off the bolts to take down the paging panel, and change the guide belt or paging.

3. Conveying belt deviation: it can be adjusted by adjusting the tension bolt at the end of the conveying.

4. For paging problems, please refer to the adjusting steps in the Instruction about Operation.

5. Conveying belt motor doesn’t rotate: check whether the inverter speed is setas zero or not; check whether the run/stop button is pressed down or not;

whether the guide belt, paging belt, or conveying belt is blocked by product or impurity, or by deviation of products?

6.All bearings of rotating parts shall be added with lubrication oil periodically. If there’s any trouble that you cannot settle, please contact the manufacturer.

2.Abrasion of guide belt and paging belt: the machine shall be shut down when no product is put on, thus to reduce abrasion. For normal abrasion, please change the guide belt and paging belt: screw off the bolts to take down the paging panel, and change the guide belt or paging.

3. Conveying belt deviation: it can be adjusted by adjusting the tension bolt at the end of the conveying.

4. For paging problems, please refer to the adjusting steps in the Instruction about Operation.

5. Conveying belt motor doesn’t rotate: check whether the inverter speed is setas zero or not; check whether the run/stop button is pressed down or not;

whether the guide belt, paging belt, or conveying belt is blocked by product or impurity, or by deviation of products?

6.All bearings of rotating parts shall be added with lubrication oil periodically. If there’s any trouble that you cannot settle, please contact the manufacturer.

FAQ

Похожие товары

Лента Конвейерная цифровая рулонная для принтера этикеток

US $200.00-$300.00

Китайский поставщик, конвейер для кормления пищевых порошков, цена

US $999.00-$2999

KF-200CS/300CS портативные тепловые уплотнители 200 мм/300 мм (15 мм)

US $10.00-$300.00

Машина Для Гофрирования гофрированного картона 320*1650

US $15000-$30000

Машина для кодирования и печати лотков для яиц E6

US $3000-$3200