Низкая потребления машина для производства песка агрегат

- Категория: Sand Making Machinery >>>

- Поставщик: Henan,Liming,Heavy,Industry,Science,&,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 154700.66 $* | 162435.34 $* |

| Aug-19-2025 | 153400.41 $* | 161070.16 $* |

| Jul-19-2025 | 128700.4 $* | 135135.92 $* |

| Jun-19-2025 | 150800.9 $* | 158340.11 $* |

| May-19-2025 | 131300.45 $* | 137865.20 $* |

| Apr-19-2025 | 148200.38 $* | 155610.42 $* |

| Mar-19-2025 | 146900.32 $* | 154245.83 $* |

| Feb-19-2025 | 145600.1 $* | 152880.34 $* |

| Jan-19-2025 | 144300.45 $* | 151515.82 $* |

Характеристики

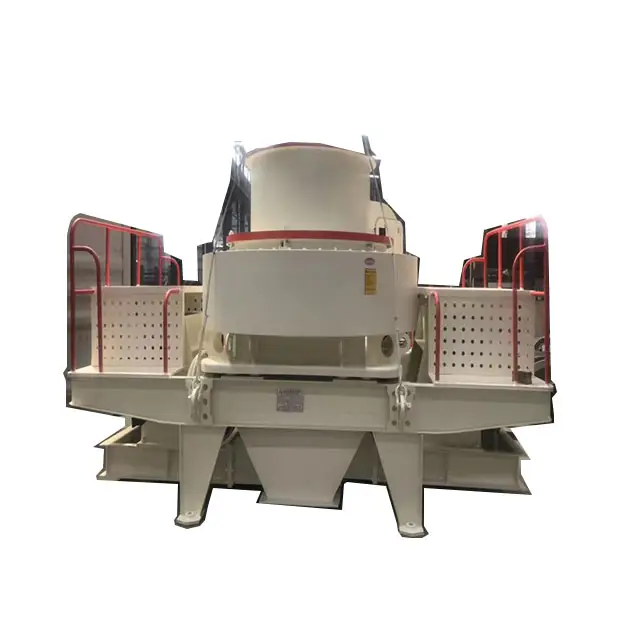

Low Consuming Sand Making Machinery for Aggregate Optimization

Liming VU Aggregate Optimization System

Liming VU Aggregate Optimization System

Advantages

- Good Particle Shape

The output shape can rival natural sand (Real product rate can be 58%-59%).

![2.36-4.75.jpg]()

![1.18-2.36.jpg]()

![0.6-1.18.jpg]()

2.36~4.75mm

1.18~2.36mm 0.6~1.18mm Low Consuming Cost

New innovated technology combines performance and technology of equipment reasonably, realizes low consuming cost.

Adjustable Fineness

The fineness is adjustable easily (2.2-3.2).

Precise Grading

The grading is more precise than before. By using water mixing machine wet sand can be produced.

Dust-proof and Environmental

Full enclosed structure prevents the dust from leaking out. With no noise nor pollutant discharge, the dust-proof is absolutely of no risk at all.

The VU aggregate optimization system of Liming

Emerges as the times require

In china, the need of sand is over 10 billion tons and the total value of sand industry is more than 500 billion Yuan. But there are many limits of the existing sand industry such as the keep increasing price, the high transportation cost, the uneven quality and the shortness of the natural sand while the lower quality, the excessive trash, the bad shape of the machine-made sand. Therefore, to meet the requirement of the wide market and to make up the disadvantage of the traditional technology , the VU aggregate optimization system of Liming Heavy Industry have emerged as the times require. This optimization system adopts the advanced technologies and scientific payoffs from domestic and abroad which will provide a brand new dry sand-making solution to the problem of exiting sand-making industry and will bring a new developmental chance for sand-making, cement-making, dry blend and ready-mixed concrete making industry.

Taking the cheap and easy to get tailing, waste, construction waste, aggregate chips, and the small pebbles as the raw materials, the VU optimization system can produce the machine-made sand just like the natural sand with the dry environmental technology. The sand produced by the VU optimization widely used as the auxiliary sand of mixing plant, dry concrete, cement, aggregate quarry, and large –scale construction which can meet the huge needs of the sand market. With the enormous value of investment, the VU optimization system has been approved and welcomed by the customers.

Liming VU dry process of sand and gravel aggregate system with the most reasonable, greatest degree reproduce naturally in the process of natural sand formed broken, erosion action such as friction, natural washing, make product sand performance is improved. - 15 mm raw materials (can be stone chips, pea stone and other cheap accessible raw materials such as stone) after dealing with the VU system is reasonable and efficient, reasonable distribution, grain output fruity, controllable sand powder content, as well as dry clean, can undertake unity recycled high value-added powder (determined according to the raw material can be used).

Production Process Flow

Liming VU dry process of sand and gravel aggregate system with the most reasonable, greatest degree reproduce naturally in the process of natural sand formed broken, erosion action such as friction, natural washing, make product sand performance is improved. - 15 mm raw materials (can be stone chips, pea stone and other cheap accessible raw materials such as stone) after dealing with the VU system is reasonable and efficient, reasonable distribution, grain output fruity, controllable sand powder content, as well as dry clean, can undertake unity recycled high value-added powder (determined according to the raw material can be used).

Our Excellent Service

Our professional engineer team has started a global customer visit, to provide customers with omni-directional and heart to heart on-site service. Whether you are using our equipment or not, welcome to leave online message and get in touch with us, we will be glad to provide you with a variety of material processing technologies and complete equipment solutions in the first time.

Q: 1. To which country your products have been exported before?

A: Our products have been sold to Ecuador, Brazil, Chile, Sudan, Zambia, Kenya,Turkey, Indonesia, Malaysia, Philipines, Australia, India and so on.

Q: 2. How will you help the customer install the equipment?

A: Our senior engineer will guide the installation and commissioning as well as the initial production at site.

Q: 3. How about the wear parts supply?

A: We offer wear parts to our customer with our most favorable price. If there are problems you could not handle, we will send our technicians to your place. but you are responsible for all the cost involved.

My friend, feel free to contact me if you need any of our help.

1. What is raw material do you want to process? (stone name)

2. What is capacity do you need? (tph)

We will send the proper solution and quotation to you as soon as we get your reply.