Черный порошок угольный стержень пыли брикет экструдер

- Категория: Energy Saving Equipment >>>

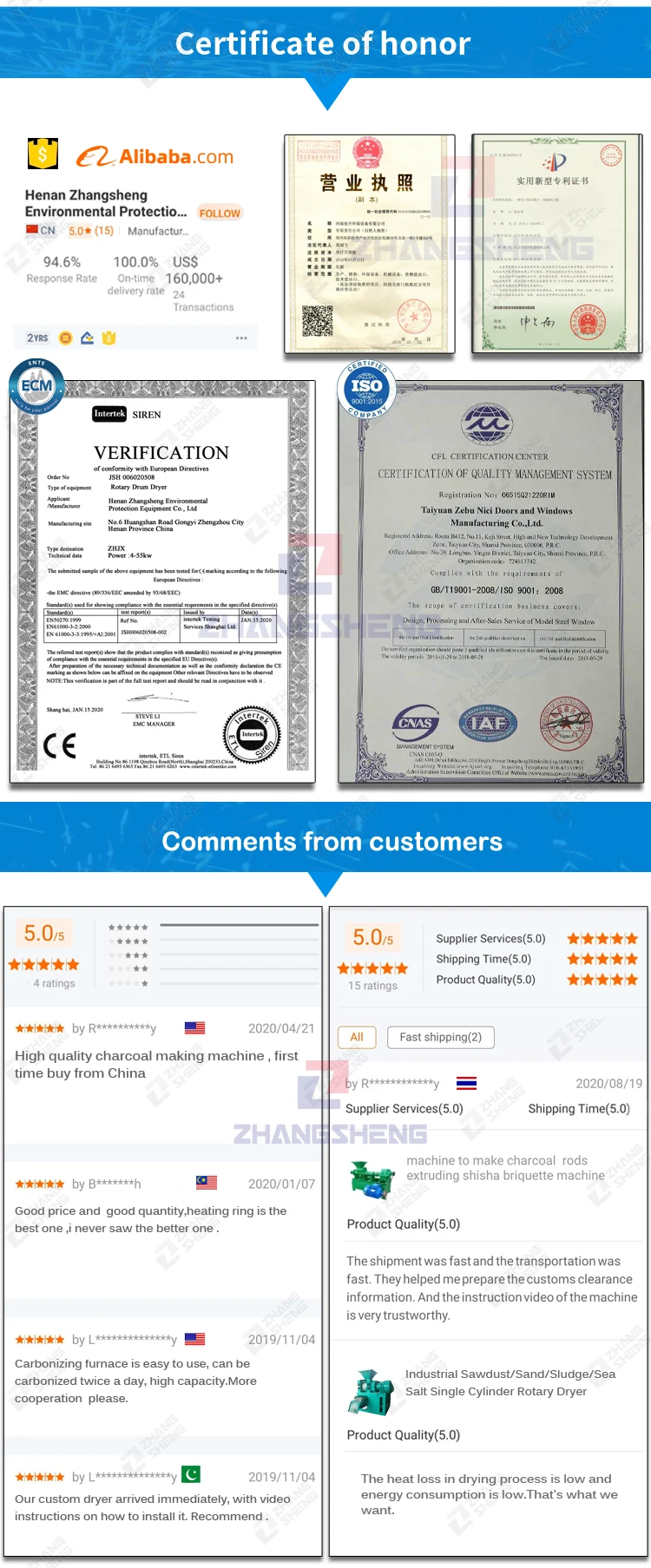

- Поставщик: Henan,Zhangsheng,Environmental,Protection,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 1666.87 $* | 1749.60 $* |

| Aug-19-2025 | 1652.87 $* | 1735.92 $* |

| Jul-19-2025 | 1386.31 $* | 1455.85 $* |

| Jun-19-2025 | 1624.84 $* | 1705.70 $* |

| May-19-2025 | 1414.60 $* | 1485.16 $* |

| Apr-19-2025 | 1596.27 $* | 1676.37 $* |

| Mar-19-2025 | 1582.15 $* | 1661.60 $* |

| Feb-19-2025 | 1568.31 $* | 1646.18 $* |

| Jan-19-2025 | 1554.65 $* | 1632.90 $* |

Характеристики

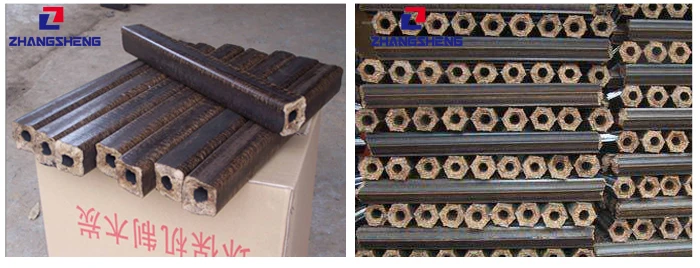

The Biomass Extrude Machine is the main molding equipment in sawdust production line. It mainly uses carbonaceous wood materials such as sawdust, sawdust, rice husk, peanut shell and plant straw, and passes through high temperature and high pressure process without any binder, extruded into a solid hollow bar.

The raw materials must meet the requirements: moisture 8%-12%, size 3-5mm.

Working principle :

The raw material that meets the requirements of the rod is placed in the feeding hopper of the equipment, and a high temperature and high pressure zone is formed under the action of the screw propeller and the heating coil, and the loose raw material is processed into a hollow rod body through the forming cylinder through spiral extrusion.

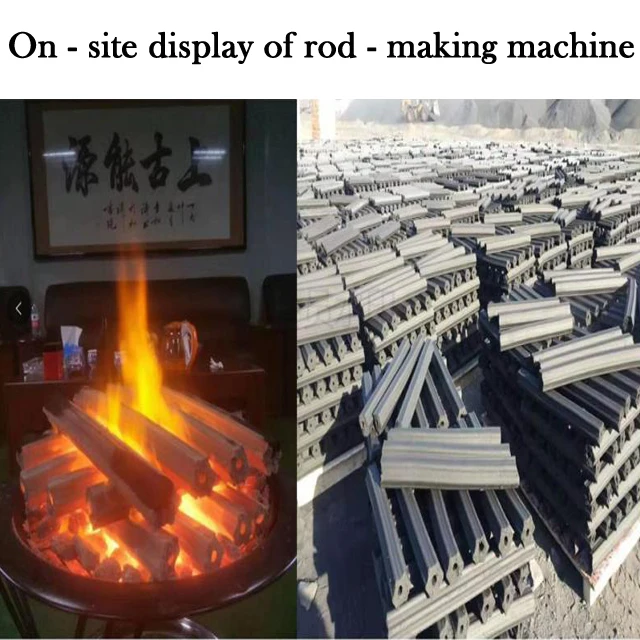

Final product :

1The available shape: square, hexagonal, hexagon with edge.

2The available diameter could be: 50mm,60mm,80mm.

3.Length could be: 20cm,30cm, 40cm, 50cm

4.Gravity: 1300—1900kg/m³ Calorific value: 4500-5000kcal/kg.

If your raw material is biomass wood sawdust, there are several steps to make briquettes:

If your raw material is biomass wood sawdust, there are several steps to make briquettes:

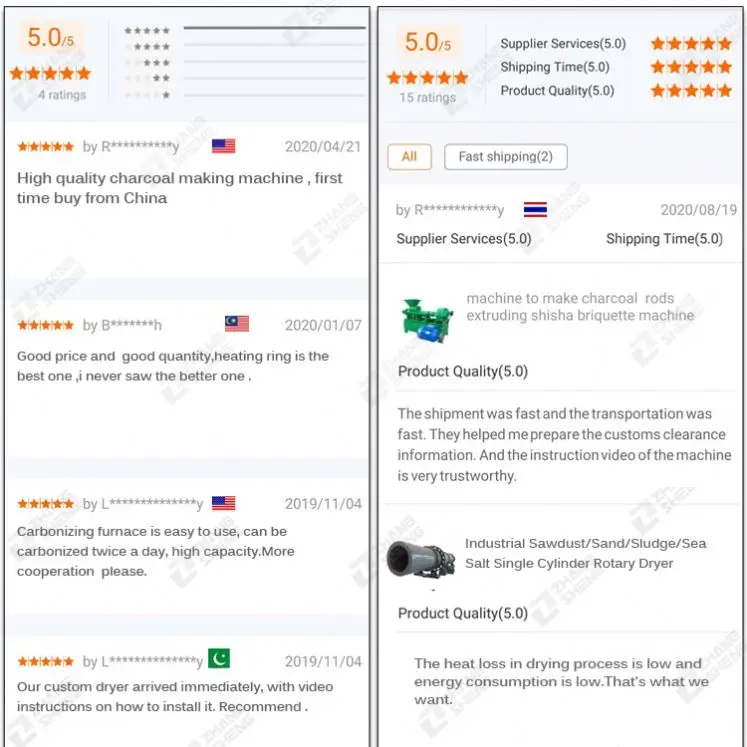

We are a professional charcoal machine manufacturer in China. We have more than 20 years of experience in manufacturing charcoal machines. We can provide you with the following services:

Q1. What's your advantage? How to install?

1) We have 15 years of working experience. The real production plant of 200 workers has the most professional technology and team. Price is more advantageous.

2) Provide installation videos, or arrange for engineers to communicate with you directly on installation methods.

3) We have overseas engineer services and can provide free training for on-site staff.

Q2. How long is your delivery time?

If there is stock, it usually takes 5-10 days. It takes 20-30 days to customize the equipment according to your requirements.

Q3:What if the machine is damaged?

One-year warranty and comprehensive after-sales service. After this period, we will charge a lower fee to maintain after-sales service.