Машина для сушки паровых труб с подачей древесного порошка на Шри-Ланке сушилка горячим воздухом биомассе производственной линии по производству древесных

- Категория: Hot Air Furnace >>>

- Поставщик: Henan,Zhangsheng,Environmental,Protection,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 1785.90 $* | 1874.54 $* |

| Aug-17-2025 | 1770.30 $* | 1859.59 $* |

| Jul-17-2025 | 1485.39 $* | 1559.17 $* |

| Jun-17-2025 | 1740.27 $* | 1827.0 $* |

| May-17-2025 | 1515.20 $* | 1591.31 $* |

| Apr-17-2025 | 1710.16 $* | 1796.80 $* |

| Mar-17-2025 | 1695.36 $* | 1780.8 $* |

| Feb-17-2025 | 1680.8 $* | 1764.76 $* |

| Jan-17-2025 | 1665.14 $* | 1748.64 $* |

Характеристики

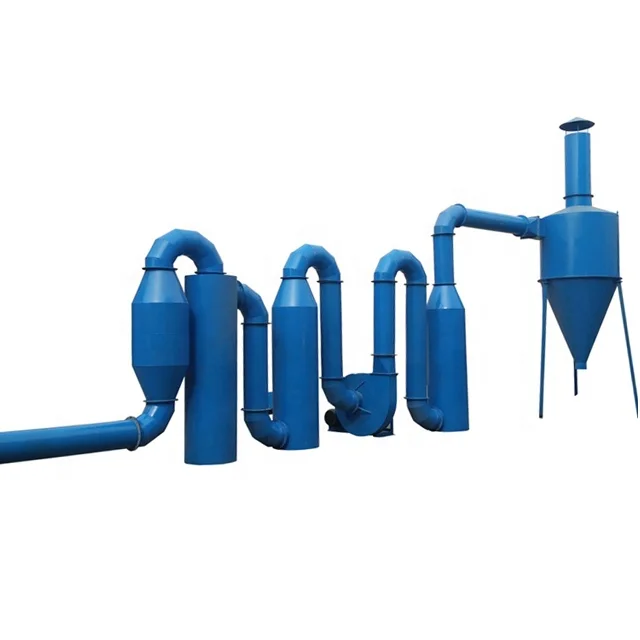

Wet material is input into the hopper. The dryer is equipped with two fuel boilers,air inlet, steel pipe, exhaust blower (fan),air lock and cyclone. Wet materials are input into the hopper. The fuel boiler generates hot air which mixes with wet materials and then is sucked into the pipes by the exhaust blower (fan) quickly. And then hot air is flowing and going though the curving pipes and buffer (drying chamber) of dryer, thus wet materials is finished to dry, and the dried materials are discharged from the outlet with air lock.

This wood dryer can reduces the moisture to 8-12%.with the advantages of lower cost consumption and high efficiency.

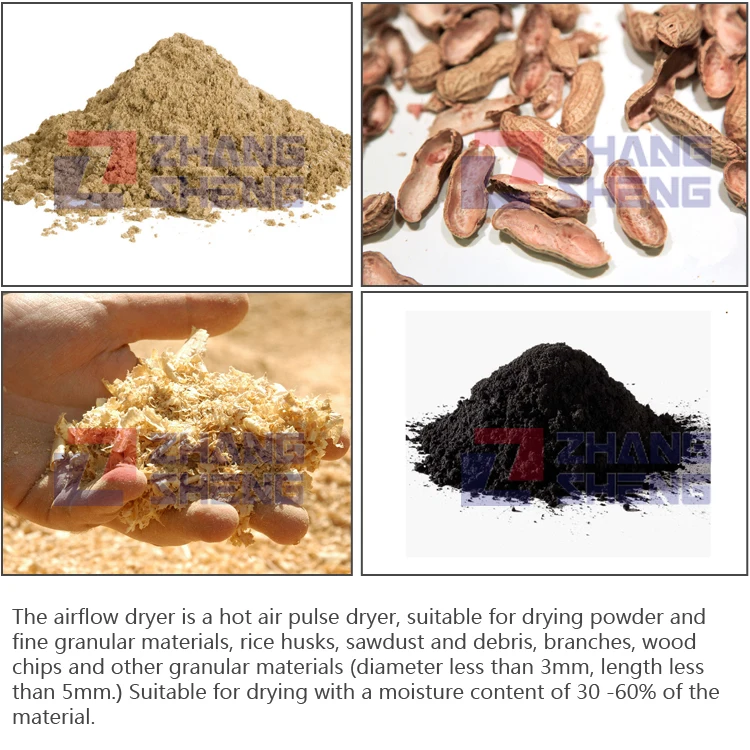

Air Flow dryer is hot air pulse dryer is suitable for drying powder and fine granular materials, rice husks, sawdust and crushed shavings, branches, wood chips and other granular raw materials(diameter less than 3mm,length less than 5mm).This dryer is suitable for drying materials of moisture 30-60%.

Air Flow dryer is hot air pulse dryer is suitable for drying powder and fine granular materials, rice husks, sawdust and crushed shavings, branches, wood chips and other granular raw materials(diameter less than 3mm,length less than 5mm).This dryer is suitable for drying materials of moisture 30-60%.

Click on the picture to view the detailed parameters of the production line!↑↑↑

If your raw material is biomass wood sawdust, there are several steps to make briquettes:

1. The frist step is crush biomass wood sawdust become small size, less than 3mm.

We are a professional charcoal machine manufacturer in China. We have more than 20 years of experience in manufacturing charcoal machines. We can provide you with the following services:

the loading picture to you.

Q1. What's your advantage? How to install?

1) We have 15 years of working experience. The real production plant of 200 workers has the most professional technology and team. Price is more advantageous.

2) Provide installation videos, or arrange for engineers to communicate with you directly on installation methods.

3) We have overseas engineer services and can provide free training for on-site staff.

Q2. How long is your delivery time?

If there is stock, it usually takes 5-10 days. It takes 20-30 days to customize the equipment according to your requirements.

Q3:What if the machine is damaged?

One-year warranty and comprehensive after-sales service. After this period, we will charge a lower fee to maintain after-sales service.