Горячая Распродажа алмазный резак с ЧПУ автоматический для ремонта литых токарный станок

- Категория: Другое оборудование для транспортных средств >>>

- Поставщик: Taian,Hiscience,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 19278.6 $* | 20242.19 $* |

| Aug-17-2025 | 19116.33 $* | 20072.47 $* |

| Jul-17-2025 | 16038.56 $* | 16840.22 $* |

| Jun-17-2025 | 18792.84 $* | 19732.86 $* |

| May-17-2025 | 16362.68 $* | 17180.47 $* |

| Apr-17-2025 | 18468.97 $* | 19391.15 $* |

| Mar-17-2025 | 18306.67 $* | 19221.11 $* |

| Feb-17-2025 | 18144.56 $* | 19051.21 $* |

| Jan-17-2025 | 17982.44 $* | 18881.71 $* |

Характеристики

Our company developed the vertical wheel repair lathe. The machine covers a small space, can be designed to meet different space request.The 2 axis of wheel lathe adopt the most stable gantry structure.The structural body is made of cast iron and resin sand casting. The Z axis is driven by four linear guides, double ball screws and double servo motor. Meanwhile, the counterweight is used to balance the zaxis with a large load bearing capacity,which effectively ensures the influence of the two axes due to different stress structures. The cutting feed in the process of wheel repair can keep sensitive control response and achieve the perfect alloy wheel repair effect.

Our company developed the vertical wheel repair lathe. The machine covers a small space, can be designed to meet different space request.The 2 axis of wheel lathe adopt the most stable gantry structure.The structural body is made of cast iron and resin sand casting. The Z axis is driven by four linear guides, double ball screws and double servo motor. Meanwhile, the counterweight is used to balance the zaxis with a large load bearing capacity,which effectively ensures the influence of the two axes due to different stress structures. The cutting feed in the process of wheel repair can keep sensitive control response and achieve the perfect alloy wheel repair effect.

DCM35P Wheel repair lathe Advantages:

l The Max.wheel repair size can up to 32 inch;

l Two-axis adopts linear guide rails and ball screws for precise control;

l The gantry structure can ensure perfect wheel repair effect from the center to the edge;

l Cast iron body, strong rigidity, avoiding the vibration texture caused by the wheel during the cutting process;

l The main servo motor can maintain strong torque at different speeds;

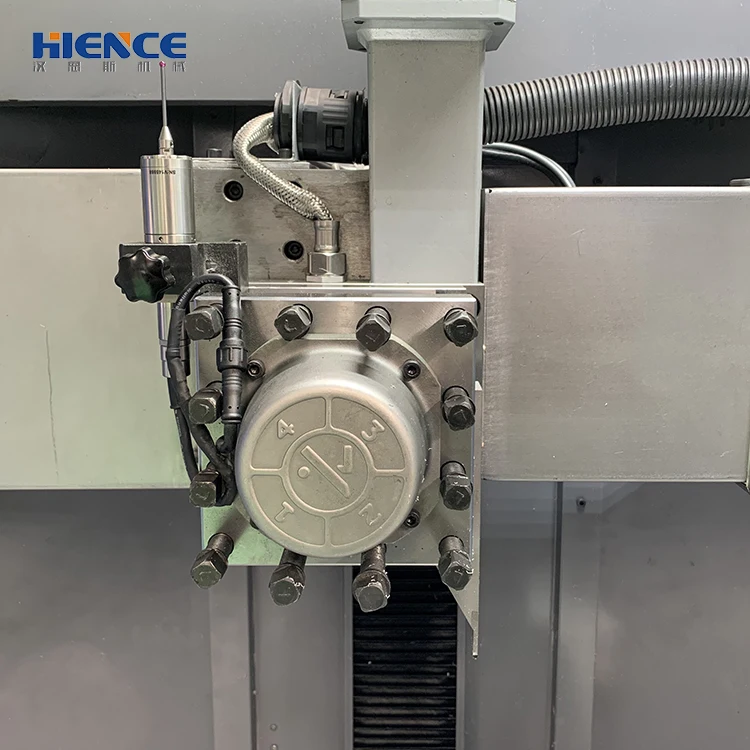

l Automatic tool holder: the tool and detection station conversion can be realized by CNC system;

l Guide rail and screw are fully closed and protected to avoid precision damage caused by the entry of aluminum chips;

l Automatic lubrication system is used for main moving parts;

l Can choose different machine appearance;

ITEMS | DCM35P-2 |

Max wheel repairable size (inch) | 5 inch~32 inch |

Max. wheel repair width(mm) | 550 |

X axis guide rail type/Number | Linear guide rail / Double |

X axis driving torque | 6N·M |

Max. Stroke of the Z-axis (mm) | 750 |

Z axis guide rail type/Number | Linear guide rail / 4 piece |

Z axis Driving motor power | 2×6N·M |

Range of spindle speed (RPM) | 50~1500 |

Spindle speed control | Servo control |

Spindle motor power | 5.5KW(Servo motor) |

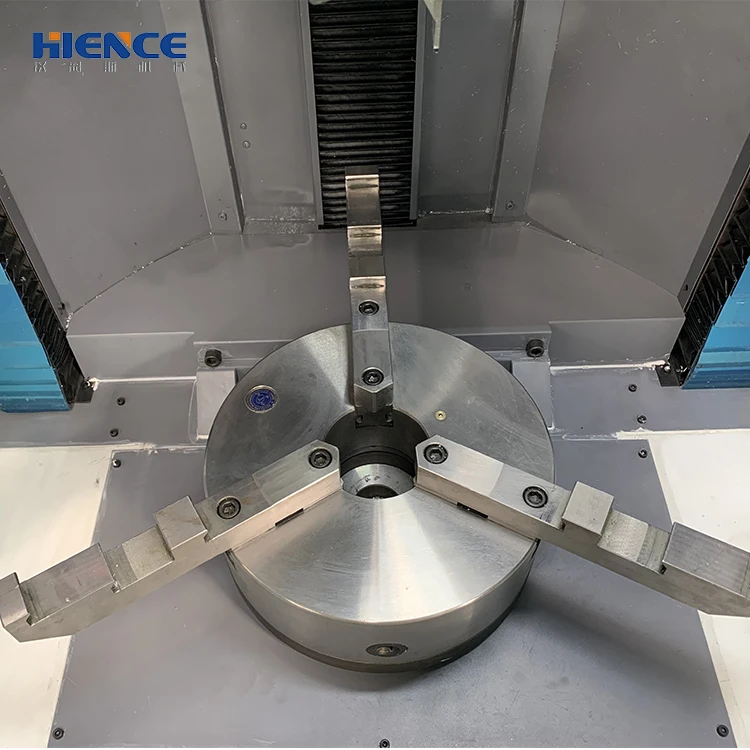

Number of jaws | 3 extended jaws |

Chuck diameter | 320mm |

Min. setting unit of motor | (Z) Long 0.001mm; (X) Cross 0.001mm |

Moving speed of post | (Z)Long 12m/min; (X) Cross 16m/min |

Stations of tool changer | 4 position |

Max. size of cutter holder | 25×25mm |

Tool changer control method | Automatic |

Machine size(L/W/H) (mm) | 1690×1200×1870 |

Machine Weight | 1500KG |

Machine Voltage | 3 phase 380V |

Q:What is the difference between vertical wheel repair machine and horizontal machine ?

A:The vertical machine is more convenient to clamp wheel and occupy a smaller space; But in terms of the force structure of the 2 axis, the horizontal machine is superior to the vertical machine, but we solved the problem, so if you choose the vertical machine, please carefully choose the experienced manufacturer.

Q:What is the advantages of your vertical wheel repair machine ?

A:The 2 axis adopt the most stable gantry structure.The structural body is made of cast iron and resin sand casting. The X/Z axis is driven by linear guides, double ball screws and servo motors. The machine uses perfect structure and parts to achieve the perfect alloy wheel repair effect.

Q:Is the operation of the machine easy to learn and operate ?

A:Our company provides detailed operate instructions and training vedios. Our professional after-sales service team can provide remote technical guidance to help customers carry out systematic and comprehensive learning; Customers can learn and master all operations in a short time from our company's market experience in more than 80 countries around the world. Customers can also choose to arrive our factory for free training, or provide paid face-to-face training services to customers' countries according to customer requirements.