YGM75 YGM85 YGM95 YGM130 YGM160 Raymond мельница высокого давления для

- Категория: Mine Mill >>>

- Поставщик: Shanghai,Clirik,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 2391978.95 $* | 2439818.9 $* |

| Jul-19-2025 | 1939950.36 $* | 1978749.38 $* |

| Jun-19-2025 | 2354309.74 $* | 2401395.44 $* |

| May-19-2025 | 2335474.15 $* | 2382183.66 $* |

| Apr-19-2025 | 1864613.56 $* | 1901905.79 $* |

| Mar-19-2025 | 2297805.60 $* | 2343761.89 $* |

| Feb-19-2025 | 2278971.46 $* | 2324550.19 $* |

| Jan-19-2025 | 2260136.70 $* | 2305339.71 $* |

Характеристики

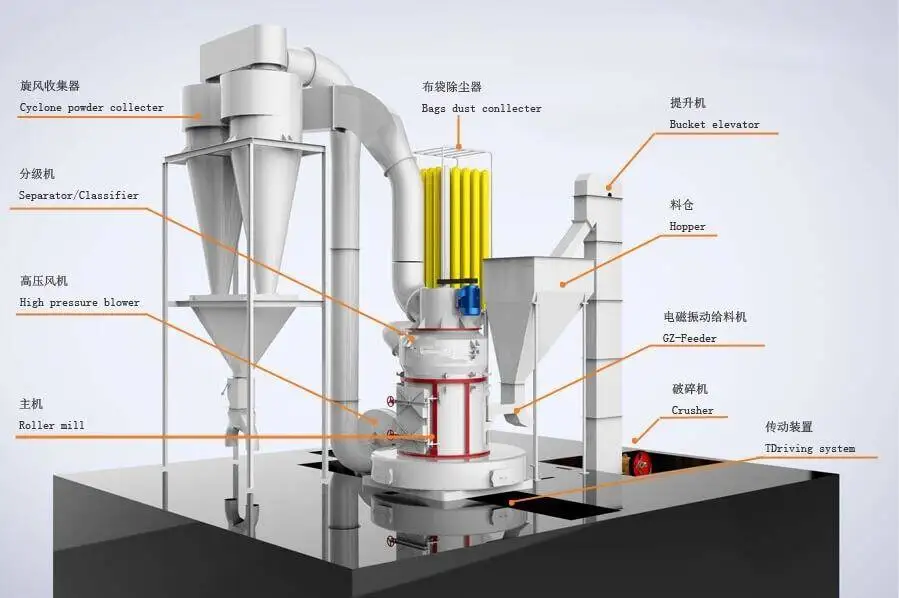

Introduction of YGM75 ,YGM85 ,YGM95 ,YGM130 ,YGM160 Raymond Mill High Pressure Grinding Mill For Stone

Raymond mill widely used in grinding equipment of mine, cement, chemical industry, is one of the important equipment of non metallic mineral deep procession. Since its strong stability,adaptability and high cost performance it has popularized in non metallic mineral processing field. Applied in grinding various non plastic ore, mineral soil,metallic oxide, chemical composition etc. which Mohs hardness not more than grade 7,humidity less than 6% non flammable and combustible material such as speckstone, dinas rock, graphite, fluorite, magnesia stone, bentonite, kaoline, pottery clay etc.

Features of YGM75 ,YGM85 ,YGM95 ,YGM130 ,YGM160 Raymond Mill High Pressure Grinding Mill For Stone

1. High capacity, 1-20t/h.

2.The fineness can be adjusted between 50 and 325 mesh (315-45 micron).

3. Fixed with 1000-1500kg pressure springs, and its capacity increase 20% to 30%; When the grinding roller and grinding ring, stable capacity and fineness can be guaranteed.

4. Easy maintenance, simple structure, low investment

5. Environment-friendly. Application of pulse bag filter & muffler greatly alleviates dust pollution and noise.

6. Advanced intelligent speed control device. Convenient adjusting, uniform particle size.

The machine has the following characteristics:

1. The reducer adopts a new type of deceleration device: the main engine speed can be adjusted according to different working conditions, and the main engine speed can be adjusted to adapt to different hardness materials.

2. Large amount of shovel: use an enlarged blade to maximize the feed of material into the grinding roller and the ginding ring.

3. The mainframe structure is advanced: the main machine adopts the buffer device, the main cover tube structure is optimized, the operation is stable and the noise is low; the main machine and the analysis machine adopt the quick change pressing device, and the maintenance is convenient. The base of the main unit is raised, the grinding roller and the grinding ring are raised to 280 mm, which increases the grinding area.

4. High classification precision: The use of ultra-large grading turbines has a high pass rate and a large air volume. And the end surface of the classifying impeller sealing blade and the sealing end surface of the powder discharging port form a palace seal, and it is not easy to form a short circuit powder, and the classification precision is high.

5. Double cyclone collector: Parallel double cyclone collector, collection efficiency of up to 80%,10% higher collection ffciency than single cyclone ollector.

6. Curved non-resistance air duct: The air duct adopts a curved non-resistance air duct design to reduce wind resistance, reduce air volume loss, and make material flow direction good, thereby increasing the analyzer's powder selection rate.

7. New grinding roller device: The grinding roller device adopts a new maintenance-free structure, and the sealing is reliable. The bearings are lubricated with oil, low fuel consumption and low maintenance cost.

8. Large conveying capacity: the air blower adopts a high-pressure centrifugal fan, and the air volume and air pressure increase, which greatly improves the pneumatic conveying capacity.

9. The wind is collected in a cloth bag, no dust pollution.

Working Principle of YGM75 ,YGM85 ,YGM95 ,YGM130 ,YGM160 Raymond Mill High Pressure Grinding Mill For Stone

Big materials are crushed by jaw crusher to the required particle sizes, and carried by bucket elevator to the storage hopper, and are fed evenly and continuously by vibrating feeder into the main unit for grinding. The bevel gear drives the central shaft to the rotate ,the shaft top is connected with a grinding roller hanger,on which a grinding roller device is mounted to form a swinging pivot. The grinding roller device rotates around not only the central shaft but also along the grinding ring,with the grinding roller rotating itself under the action of the friction. The grinding roller hanger has a shovel blade installed at the bottom of roller, the shovel blade and grinding roller throw up and feed the material between the grinding rollers and ring during mutual rotation to form a bedding layer ,which will produce an outward centrifugal force ( an extrusion force ) by the rotation of grinding roller to crush the materials.The grinded powder are carried by the airflow from the blower to the classifier to be classified, the particles which meet the fineness enter cyclone collector through pipe, and are separated and collected there. They are discharged at the discharging valve to become finished products; the airflow is sucked to the blower by return pipe on the top of cyclone collector. The whole airflow system is a sealed circulation, and is circulated under positive and negative air pressure.

Main Unit & wearing parts of YGM75 ,YGM85 ,YGM95 ,YGM130 ,YGM160 Raymond Mill High Pressure Grinding Mill For Stone

Main technical parameters of YGM75 ,YGM85 ,YGM95 ,YGM130 ,YGM160 Raymond Mill High Pressure Grinding Mill For Stone

Why Choose YGM75 ,YGM85 ,YGM95 ,YGM130 ,YGM160 Raymond Mill High Pressure Grinding Mill For Stone?

1. Much better than traditional grinding mills

YGM series high pressure suspension grinding mill is upgraded from traditional Raymond mill, which make capacity 20% higher than Raymond mill.

2. Wide range of applications

Clirik company supply more than 200 sets YGM series high pressure mills to customers and distributors , so far, Clirik company has about 16 agents in China, such as SBM, Zenith , Liming,etc.

YGM series high pressure mills widely used for grinding calcium carbonate, talc, gypsum, feldspar, barite, pyrophyllite,dolomite,kaolin,coke,etc.

3. Adjusted output size:

50 mesh-425 mesh(35-200 micron ).Output size is adjustable by adjusting running speed of classifier.

4. High Capacity and Lower power consumption:

|

YGM9517 high pressure suspension grinding mill - calcium carbonate |

|||

|

Fineness (mesh ) |

Capacity(ton / hour) |

Power consumption for one ton powder (kwh /ton) |

Total line motors rated power:82.5KW |

|

80-120 |

6-5.5 |

13.7-21 |

|

|

180-200 |

5-4.5 |

23.2-25.7 |

|

|

300-325 |

3.5-3 |

33-38 |

|

5. Less Land Covering Space & less labor required :

One set YGM9517 high pressure suspension grinding mill installation cover 48 square meter space, 8 meter height . Total production line need 2-3 workers, one for raw material feeding , one for operation and maintenance , the last one for final packing .

6. Long lifecycle of wearing parts:

Our wearing parts made by high Mn material, which is designed by our technical department with Bao Group together. The normal wearing parts includes ring, roller, scraper knife and scraper knife base , normally for grinding calcium carbonate, 10 hours /day, 30days/month, they can work 12-18 months.

Related products

|

|

|

| HGM Ultrafine Grinding Mill | Gypsum Boiling Furnace | Powder Surface Coating Machine |

We supply all kinds of stone crushers and grinding mills(50-3000 mesh). →→ More information

Company Brief Introduction

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china, as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of grinding mill, from coarse grinding mill, fine grinding mill and ultra fine grinding mill, grinding mill related equipment, such as powder modifying machine, powder packing machine.powder conveying system, etc. We have devoted into grinding field for more than 30 years, we belive only focus can be professional.

Our factory

Customer Visit

Our Certificates

Our company has get ISO9001, our products have recieved CE certification and other qualifications.

1.Seaworthy packing with sheet, fixed box, etc.

2. Container Loading

3. Delivery time: 15 days after receiving deposit.

4. All payment terms are available.

Pre-sales Service:

Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment, optimized process configuration and a full range of technical support.Every customer has the chance to visit the working machinein the site before placing the order,we help to arrange cars, hotels, and translators for every visiting customer.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the calcium carbonate powder site to help install the customers' plants. Necessary training about machinedaily maintenance to local workers is provided also.

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com