Порошок для селективного лазерного спекания SLS материал ТПУ обувь ROHS REACH серебристый 3D натуральный SP501

- Категория: ТПУ >>>

- Поставщик: Guangdong,Silver,Age,Sci.&Tech.,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.51 $* | 0.49 $* |

| Aug-20-2025 | 0.95 $* | 0.92 $* |

| Jul-20-2025 | 0.85 $* | 0.15 $* |

| Jun-20-2025 | 0.21 $* | 0.18 $* |

| May-20-2025 | 0.33 $* | 0.57 $* |

| Apr-20-2025 | 0.36 $* | 0.14 $* |

| Mar-20-2025 | 0.14 $* | 0.74 $* |

| Feb-20-2025 | 0.66 $* | 0.41 $* |

| Jan-20-2025 | 0.44 $* | 0.59 $* |

Характеристики

Product Description

TPU powder-3D printing material for Seletive Laser Sintering

TPU powder is a thermoplastic hot-melt ultrafine powder, which has good adhesion to most materials, high initial peel strength and heat resistance, and a wide temperature range to meet different processing requirements.

TPU powder : 85A TPU (SP 501) 90A TPU (SP 502) | ||

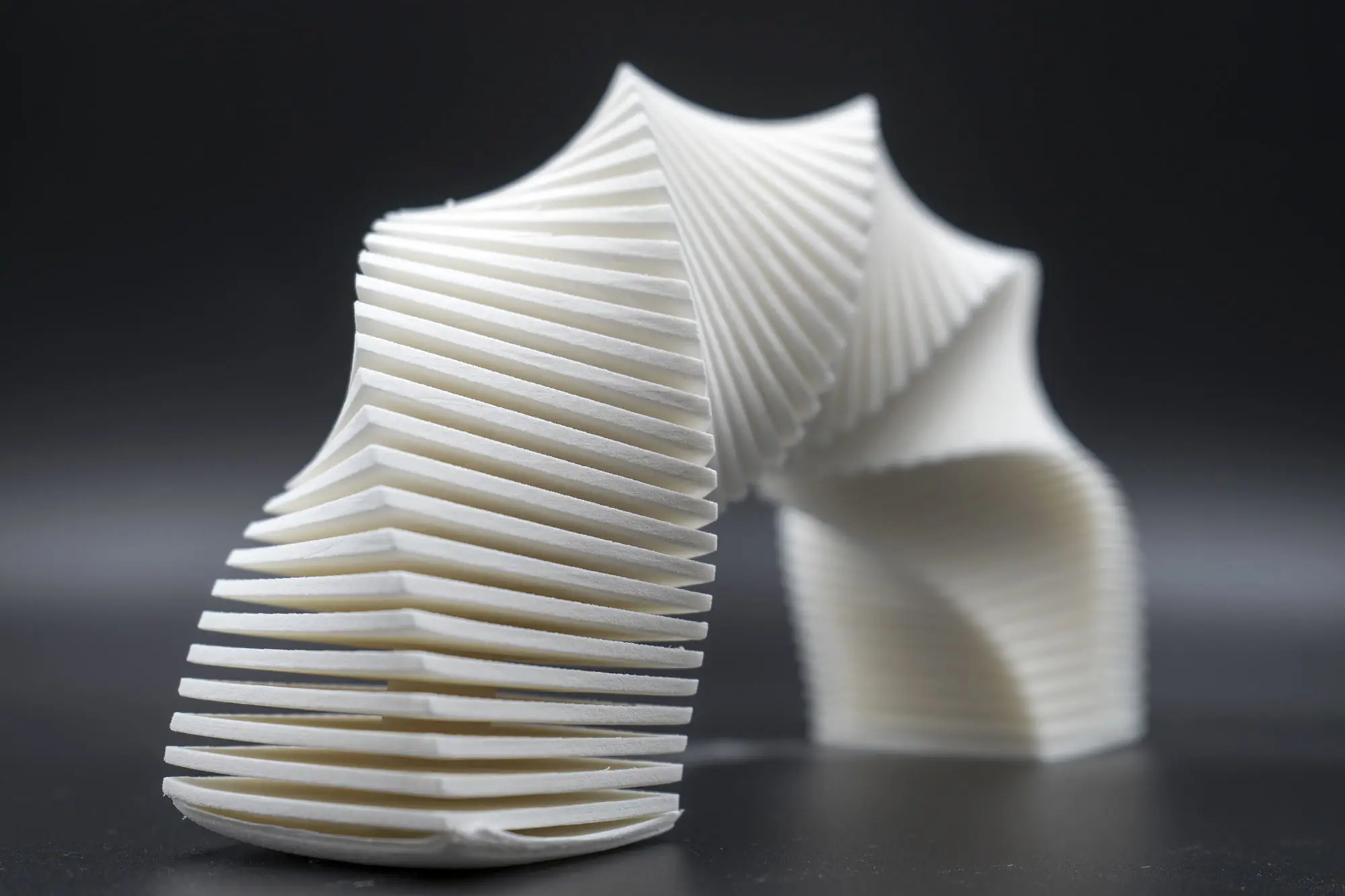

Features: 1.Soft and flexible 2.High strength 3.Good recyclability 4.Wear-resistance | ||

Application: ●Shoe amd sports industry ●Sealings ●Prosthetics ●Pippes | ||

PA powder(SP301) |

Feature: 1 High strength 2. Excellent heat resistance 3. Great repeated utilization factor (almost 10 times) |

Application: ●Aviations and aerospace industries, automobile, customer goods, etc. ●Structural component that the traditional methods failed to process. ●Rapid manufacturing of medium and small batch. ●Complex hollow structure. |

Glass bead/PA composite powder (SP304GF) |

Features: 1.Easy processing. 2.Good wear resistance. 3.High thermal deformation temperature. 4.Excellent dimensional stability. |

Application: ● High strength products. ● Complex model parts. ● Electric tool, Electrical control box. ● Automobile hood, intake manifold, etc. |

Carbon fiber/PA composite powder (SP305CF) |

Feature: 1.High rigidity, low density. 2.High thermal deformation temperature. 3.Excellent mechanical properties. |

Application: ● Products with high strength requirement. ● Lightweight components. ● Aerospace parts. ● Pneumatic components in automobile industry. |

Aluminum/PA composite Powder (SP307Al) |

Feature: 1.High strength. 2.High temperature resistance. 3.Good heat conductivity. 4.Excellent dimensional stability. |

Application: ● Metal appearance parts. ● Thermal load parts. ● Automobile manufacturing. ● Fixture and tool manufacturing. |

Test descrition | ||||||||||||

Item | methord | Unit | SP 301 PA powder | SP 304GF Glass bead PA composite powder | SP 305CF Carbon fiber PA composite powder | SP 307Al Aluminum PA composite powder | ||||||

Mean Diameter | Laser diffraction | μm | 40-55 | 40-55 | 40-80 | 30-55 | ||||||

Density of Sintered Parts | ISO 1183 | g/cm3 | 0.98 | 1.13 | 1.09 | 1.36 | ||||||

Melting Point | ISO 3146 | ℃ | 184 | 184 | 184 | 184 | ||||||

Heat deflection temperature | ISO 75-1 (1.8MPa) | ℃ | 55 | 96 | 121 | 144 | ||||||

Tensile Strength | ISO 527 | MPa | 43 | 40 | 65 | 42 | ||||||

Elongation | ISO 527 | % | 15 | 10 | 4 | 4 | ||||||

Shore A Hardness | ISO 868 | ° | — | — | — | — | ||||||

Flexural Strength | ISO 178 | MPa | 57 | 71 | 85 | 70 | ||||||

Flexural Modulus | ISO 178 | MPa | 1450 | 2200 | 3500 | 3000 | ||||||

Impact Strength | ISO 180 | KJ/m2 | 21 | 20 | 18 | 29 | ||||||

Notched Impact Strength | ISO 180 | KJ/m2 | 3.5 | 3.2 | 4 | 3.0 | ||||||

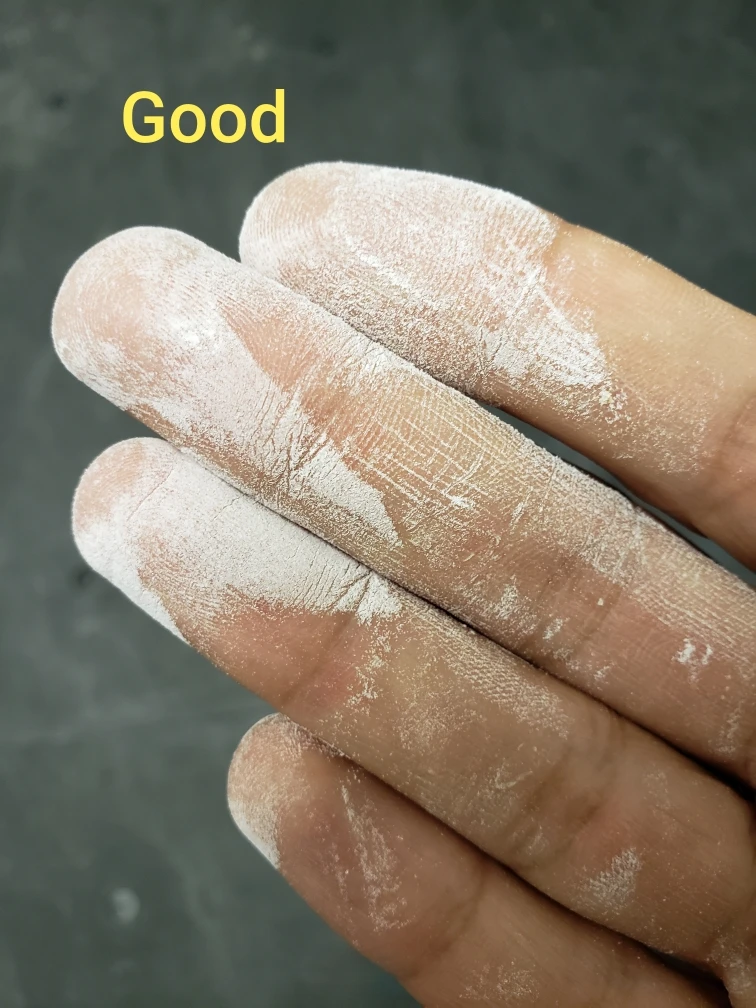

Sample display

Our Advantages

Professional 3D Printing materials Manufacturer

1. High strength and stiifiness

2. Good chemical resistance

3. Economic cost

3. Economic cost

1. Low refreshing

2. Fine granulometry

3. Easy-to-process

3. Easy-to-process

1. Excellent resolution of contour and surface

2. Excellent flow ability

Factory direct sales, Self-developed, Never use poor raw material

Why Choose Us

R & D strength

There are nearly 100 technical researchers with doctor’s or master’s degree within our company and we have a 500㎡ laboratory with CNAS national certifications.

Rich experience

Founded in 1997,National graded high-technology enterprise, manufacturing high performance 3D materials,with strong R&D, distribution and sales capabilities.

Best Service

Experienced technical personnels will provide customers with pre-sales and post-sales technical consulting, on-site technology support and problem analysis.

Packing & Delivery

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Customizable packing

1. OEM Label and Box Logo

2. OEM filament KG

3. Free OEM service

2. OEM filament KG

3. Free OEM service

Package

2. Food grade Vacuum bag & desiccant

Loading and delivery

Within 5 days after receiving payment (Normal circumstances)

Certifications

● Silver's materials are fully CE & RoHS compliant. All products come with test reports issued by SGS, providing a powerful warranty of quality.

● Our raw material is imported with top quality. And will be double QC before putting in the warehouse.

● All products have their own number which contain their production information including what time are they produced, which product line are they from.

Exhibition

Silver's global 3D show

Company Profile

Guangdong Silver Age Sci. & Tech .Co., Ltd. (Stock No.300221), established in 1997, is a national graded high-technology enterprise. We specialize in 3D printing material for many years with strong R&D, distribution and sales capabilities. Also, as a 3D printing materials research and development base, we silverage undertake Chinese national strategic emerging

industries project, focusing on key technology research projects, storm strategic delivery and processing 3D printed material critical issues.

industries project, focusing on key technology research projects, storm strategic delivery and processing 3D printed material critical issues.

Our corporate vision: To be the leader in the filed of 3D printing production.

Mission: Make 3D printing change life.

Core values: people-oriented, customer first, unity, cooperation and innovation.

Features: top quality, the most abundant species, the most intimate prices.

Mission: Make 3D printing change life.

Core values: people-oriented, customer first, unity, cooperation and innovation.

Features: top quality, the most abundant species, the most intimate prices.

FAQ

Q1: What's your warranty policy?

A1: For all the products, we have one-year warranty.

All of our goods are 100% tested working before sent to you.

In case there are unexpected damages during delivery, please do check before you sign for the package.

Q2: What's your minimum order quantity?

A2: Usually our Minimum order quantity is 1KGS.

Small orders are also welcome, but the unit price is also difference from wholesale price.

Q3: What package do you use for the products?

A3: Usually we have professional retail package for the products.

Food grade Vacuum bag & desiccant inside, then in carton

Q4: How about the payment term?

A4:.Usually we adopt T/T term. 30% T/T in advance as deposit,70% balance payment before shipment.

If you have other inquiries, please contact us to talk more.

Q5: I am very satisfied after I read your FAQ, how can I start to purchase my order?

A5: Please click the "contact supplier" at the right side of this page or contact our sales on Trade Manage online or by e-mail!↓

Q2: What's your minimum order quantity?

A2: Usually our Minimum order quantity is 1KGS.

Small orders are also welcome, but the unit price is also difference from wholesale price.

Q3: What package do you use for the products?

A3: Usually we have professional retail package for the products.

Food grade Vacuum bag & desiccant inside, then in carton

Q4: How about the payment term?

A4:.Usually we adopt T/T term. 30% T/T in advance as deposit,70% balance payment before shipment.

If you have other inquiries, please contact us to talk more.

Q5: I am very satisfied after I read your FAQ, how can I start to purchase my order?

A5: Please click the "contact supplier" at the right side of this page or contact our sales on Trade Manage online or by e-mail!↓

Don't hesitate

Contact us for more competitive price and free sample!

Mila Wu

Sale Engineer

GuangDong Silver Age Sci. & Tech. Co., Ltd.

Add: NanGe Industrial Zone, DaoJiao Town, DongGuan, GuangDong, China. P: +86-15816802779 (Whatsapp)

E: wumn@silverage.cn (Skype)

Wechat: milaqwer