Изготовленные на заказ пластиковые БПЛА компоненты для перенапряжения от

- Категория: Пресс-формы >>>

- Поставщик: Shenzhen,Rjc,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.7 $* | 0.34 $* |

| Aug-16-2025 | 0.79 $* | 0.45 $* |

| Jul-16-2025 | 0.62 $* | 0.18 $* |

| Jun-16-2025 | 0.51 $* | 0.67 $* |

| May-16-2025 | 0.63 $* | 0.3 $* |

| Apr-16-2025 | 0.99 $* | 0.36 $* |

| Mar-16-2025 | 0.88 $* | 0.50 $* |

| Feb-16-2025 | 0.69 $* | 0.99 $* |

| Jan-16-2025 | 0.35 $* | 0.26 $* |

Характеристики

Our Service | Plastic Material |

High precision plastic injection mould High precision Stamping mould High precision Silicone Mould | PP ABS PA66 PC TPU PPE ETC PA POM PBT PS PMMA SAN |

Molding Standard | Molding Structure |

DME HASCO LKM MISUMI OEM | 2 Plate mold Second injection 3 Plate mold Delayed injection Inverted mold Gas injection system Inner slider Hot runner system Angle slider Hydraulic Cylinder system Big angle lifter ETC |

Finish Result | ||

As Machined | Sharp edge and burrs will be removed | |

Bead Blast | The part surface is left with a smooth, matte appearance | |

Anodized | Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. | |

Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. | ||

Powder Coat | This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic. | |

Customized | Cotact us via email,skype,whatsapp. We will look into a finishing process for you. | |

Others | ||

Tolerance | +/-0.005mm | |

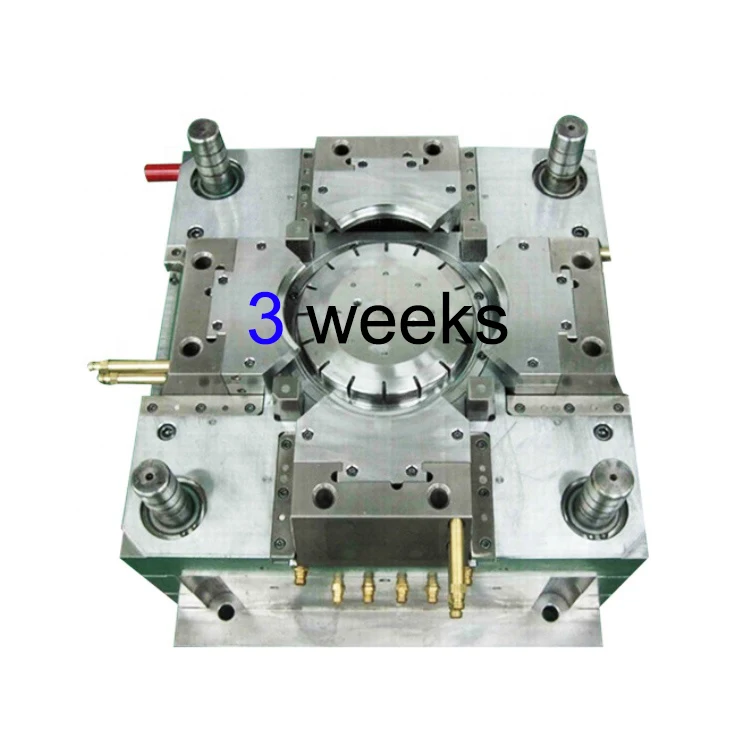

Lead Time | 1-2 weeks for samples,3-4 weeks for mass production | |

Drawing Accepted | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF | |

Payment Terms | Trade Assurance, TT/Paypal/WestUnion | |

Information | ||||||

Mold No. | JC180025 | Project Surface | CM²/per part | |||

Part Name | Plate | Part Volume | CM³ /per part | |||

Resin | ABS | Runner Volume | 0CM³ /per part | |||

Visible Surface | texture | Shrinkage | 0.5% | |||

Machine Information | ||||||

Part Pick Up | Auto | Machine Type | 80T | |||

Runner Pick Up | Auto | Estimated Cycle | 45S | |||

Remark | Estimate annual output quantity is 300K units | |||||

RJC Industrial Co., Ltd was established in 2002,it has grown up to be one of the highly reputable supplier in terms of the service of mold manufacturing,injection molding , CNC machining ,CNC lathing and so on .

Up to now , RJC has dedicated team to support oversea business in terms of business development , engineering support and continuous improvement to guarantee better schedule and quality delivered.

Radial drilling machines | 5 sets |

Laser carving machines | 8 sets |

Milling machines | 13sets |

WEDM machines | 5 sets |

Grinding machines | 10 sets |

CNC lathe machines | 20 sets |

EDM machines | 13 sets |

Precision CNC machines | 35 sets |

Q1:Where can I get product&price information?

A1:Send us inquiry e-mail , we will contact you as we receive your mail.

Q2:How long can i get the sample?

A2:Depends on your specific items,within 3-7 days is required generally.

Q3:What's kinds of information you need for quote?

A3:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS

Q4: what's the payment terms?

A4: We accept 50% as payment deposit, when the goods is done, we take photoes for your check and you then pay the balance.For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred

Q5: How to delivery the goods?

A5:We deliver the products by courier company

Q6.Are you a trading company or factory?

A6:We are direct factory with 17 experienced engineers and more than 50 employees as well approximate 5,000 square meters workshop area.

Q7. What shall we do if we do not have drawings?

A7. Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q8. Can we get some samples before mass production?

A8:Absolutely

Q9. Will my drawings be safe after sending to you?

A9:Yes, we will keep them well and not release to third party without your permission.

Q10: Is it possible to know how are my products going on without visiting your company?

A10: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q11: If you make poor quality goods,will you refund our fund?

A12: As a matter of fact, we won't take a chance to do poor quality products. Meanwhile, we manufacture goods quality products until your satisfaction.