HaiQi новейшая технология удаления смолы биомасса

- Категория: >>>

- Поставщик: Henan,Haiqi,Environmental,Protection,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 104720.45 $* | 109956.14 $* |

| Aug-18-2025 | 103840.74 $* | 109032.36 $* |

| Jul-18-2025 | 87120.5 $* | 91476.7 $* |

| Jun-18-2025 | 102080.21 $* | 107184.1 $* |

| May-18-2025 | 88880.18 $* | 93324.55 $* |

| Apr-18-2025 | 100320.61 $* | 105336.32 $* |

| Mar-18-2025 | 99440.30 $* | 104412.25 $* |

| Feb-18-2025 | 98560.5 $* | 103488.61 $* |

| Jan-18-2025 | 97680.67 $* | 102564.83 $* |

Характеристики

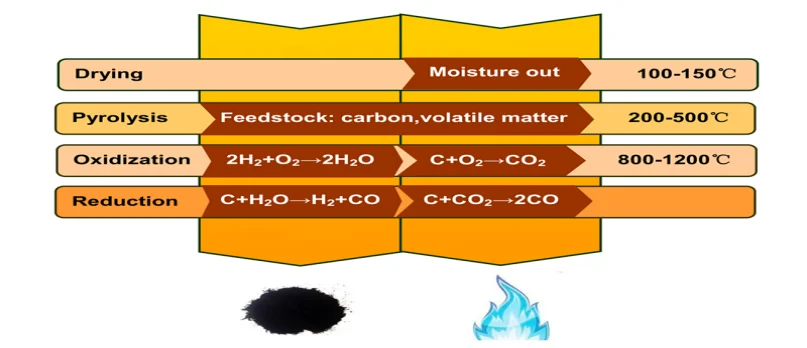

Principle of pyrolysis and gasification

Biomass gasification refers to the thermochemical process of converting biomass fuels into flammable gases. In this process, water vapor, free oxygen, or bound oxygen reacts with the carbon in the fuel to form a combustible gas. Biomass gasification process is more complex and the gasification reaction conditions are also different. However, all the gasification reaction processes basically include the processes of biomass drying, pyrolysis, oxidation and reduction.

Core Features

1.The direction of the combustible gas in the downdraft gasifier is the same as that of the biomass. Usually, the high-temperature oxidation zone is set, and the combustible gas is sucked out from the lower part of the grate. The structure of the downdraft gasifier makes the combustible gas must pass the high-temperature oxidation. The zone is conducive to the further cracking of tar, and the tar content in the gas is in the range of 50-500 mg/M3. Compared with the upper suction type (10-100 g/M3), the tar content is small.

2.With reasonable structure, it adopts a fixed bed downdraft gasifier, vertical feeding, hydraulic reciprocating slagging, automatic cleaning, low tar content and stable gas production. High degree of automation: the control system adopts PLC controller, interconnection and interlocking, automatically eliminates potential safety hazards in case of faults, and automatically senses and ejects slag after feeding. The system is easy to understand, operation is easy to use, one is on duty,safe and reliable.

3.Furnace body protection is good, the furnace body adopts water circulation cooling, and the furnace temperature is stable and can work continuously for 24 hours.The advantages of environmental protection are obvious, ash content is lower than 1-1.5%, trace sulfur dioxide, carbon dioxide emissions, and flue gas are less than 50mg/m3

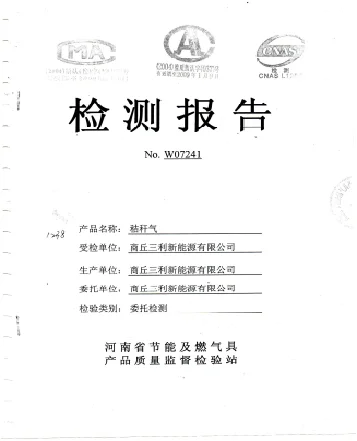

Syngas Gas component table

| Test Report | No. | Test item | Test result | |

| 1 | Component | O2 | 2.30% |

| 2 | N2 | 48% | ||

| 3 | CH4 | 5.00% | ||

| 4 | CO | 10.50% | ||

| 5 | CO2 | 21.3% | ||

| 6 | H2 | 11.8% | ||

| 7 | CMHN | 1.10% | ||

| 8 | Caloric value | 5.188MJ/m³ | ||

| 1238.1kcal/m³ | ||||

| 9 | Relative density | 97.32% | ||

Cooperation Method

1.Equipment Purchase and Sale.

2.Equipment Agency or Agency Sales .

3.Contract energy management.

Our Service