D11 D8 D10 наконечник бульдозера хвостовик Бульдозера для

- Категория: Рыхлители >>>

- Поставщик: Shandong,Higher,Blades,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.80 $* | 0.14 $* |

| Aug-18-2025 | 0.10 $* | 0.68 $* |

| Jul-18-2025 | 0.45 $* | 0.15 $* |

| Jun-18-2025 | 0.72 $* | 0.59 $* |

| May-18-2025 | 0.30 $* | 0.81 $* |

| Apr-18-2025 | 0.30 $* | 0.21 $* |

| Mar-18-2025 | 0.90 $* | 0.47 $* |

| Feb-18-2025 | 0.52 $* | 0.54 $* |

| Jan-18-2025 | 0.97 $* | 0.24 $* |

Характеристики

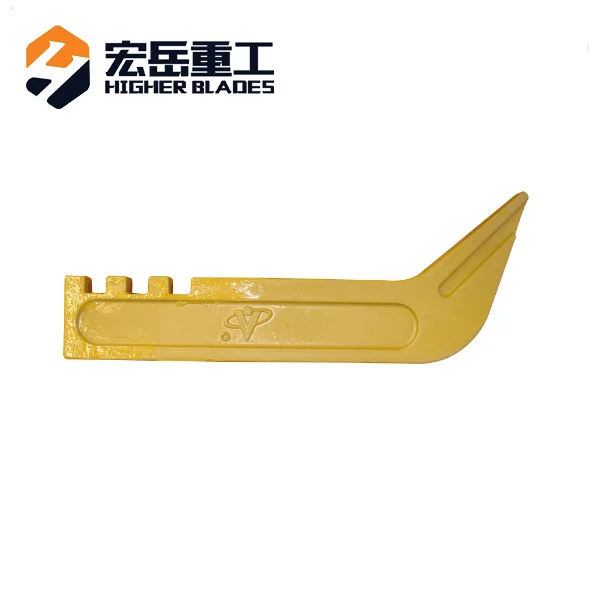

D11 D8 D10 bulldozer shank tip Dozer ripper shank for Caterpillar

Higher Blades cutting edge manufacturer is the only one GET(cutting edge, end bit, grader balde, ripper shank) factory in China ---who can also engaging steel material directly!

Higher Blades has the advantage material for ripper shank. the shanks will need the good quality mechannical property for mining constructions.

The hardness of ripper shank is 40 HRC with the best hear-treatment , can increase the shank tip wear life.

Shandong Higher Blades Technology Co., Ltd. | |

Product Name | D11 D8 D10 bulldozer shank tip Dozer ripper shank for Caterpillar |

Size | 110mm |

Material | Carbon steel or Boron steel |

Colors | Black or yellow or your customised one |

Certification | ISO9001/ISO14001/OHSAS18001 |

Delivery Time | Within 15-30 days after contract established |

Cutting edge applied to construction sites

Welding bucket blade or base blade ,Bolt-on cutting edge ,Bucket guard, segment, Half-arrow blade, dozer blade, dozer end bit, grader blade and ripper shank for mining machine.

Higher Blades cutting edge can produce double and single bevel, which is based on every customer’s demand.

Adcanced heat-treatment with through hardning, Core hardness is higher to extend waer life.

Higher Blades can also supper dozer end bit, grader end bit, and ripper shank for mining equipment.

Why choose your company?

- Germany plasma cutter machine to ensure cutting edge cutting accuracy.

- Core technique: Heattreatment---Korea heattreatment line with auto control, all the temperature and volume of water can be recorded, which ensure the cutting edge without deformation-the core hardness and surface hardness ≤ 5HRC, “through harden” is attainable.

- Raw material is directly from SISG or BAO steel group. We are first class agency of these two top steel group, so our raw material is cheaper than our competitors.That is why our cutting edge is cheaper

Higher Blades is a professional manufacturer for ground engaging tools such as cutting edge, blades, end bit, ripper shank, teeth used on earth moving spare parts including grader, bulldozer, loader, excavator.

Our parent company Tieshi Trading provides raw material for cutting edge, end bit, and grader blade from the top steel mill in China.Annual supply for steel is over 700000 tons.Costing advantage for blade based on bulk purchasing.Innovative material design ability as technical requirement

Higher Blades is a professional manufacturer for ground engaging tools such as cutting edge, blades, end bit, ripper shank, teeth used on earth moving spare parts including grader, bulldozer, loader, excavator.

Our parent company Tieshi Trading provides raw material for cutting edge, end bit, and grader blade from the top steel mill in China.Annual supply for steel is over 700000 tons.Costing advantage for blade based on bulk purchasing.Innovative material design ability as technical requirement

Advanced Facility

Higher Blades equipped most advance heat treatment line in the industry. We can ensure higher hardenability on both surface and the core of the material. So that we can provide longer working life and consistant quality.

Higher Blades owned the most advanced equipment such as Germany Kjellberg CNC laser plasma cutting machine, higher speed drill machine, punching & drilling co-process machine.We imported large advanced auto-roller heat-treatment ling from Korea which is the best heat-treatment line in China.

Its “through hardening” technology can extend cutting edge, end bit, grader blade and ripper shank wear life and ensure the quality consistency.

All those make "Higher Quality Higher Blades"

We have in-process and and finished product quality control from every production process all make sure the blades quality, if finding some problems before shipping , we will produce new again to promise the higher quality.

Higher Blades have Chinese top Laboratory to test hardness, tensile strength, impact energy for the cutting edge, grader blade, end bit and ripper shank.

Brinell/Rockwell Hardness Tester, Impact Energy Tester promising cutting edge have good mechonical property, which prolong cutting edge, end bit, grader blades and ripper shank wear life.

Customers visited factory and our exhibition booth of cutting edge, talking about the grader blade production process and the advantaged heat-treatment line.

Package | Standard Export Package |

Delivery Time | 15 work days after receiving the payment |

Type | Carton pallet and Plywood block |

Cutting edge ,grader blade and ripper shank ready to ship, or are loading the containers to all over the worlds.