3d деревообрабатывающий станок с ЧПУ 1325 2030 для резьбы

- Категория: Станок по дереву >>>

- Поставщик: Jinan,Hitec,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 4165.69 $* | 4373.62 $* |

| Aug-18-2025 | 4130.71 $* | 4337.11 $* |

| Jul-18-2025 | 3465.94 $* | 3638.48 $* |

| Jun-18-2025 | 4060.96 $* | 4263.81 $* |

| May-18-2025 | 3535.58 $* | 3712.49 $* |

| Apr-18-2025 | 3990.1 $* | 4190.6 $* |

| Mar-18-2025 | 3955.36 $* | 4153.14 $* |

| Feb-18-2025 | 3920.29 $* | 4116.23 $* |

| Jan-18-2025 | 3885.13 $* | 4079.8 $* |

Характеристики

CNC router Application

Woodworking industry: three-dimensional wave board processing, cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, process fan window processing, shoe-shoes, game consoles and panels, mahjong tables, computer tables and auxiliary processing of panel furniture products .

Advertising industry: the production of advertising signs, logo production, acrylic cutting, plastic molding, and a variety of materials advertising decorative products.

Mold industry: It can engrave metal molds such as copper, aluminum and iron, as well as non-metal molds such as artificial marble, sand stone, plastic board, PVC pipe and wood board.

Other industries: It can engrave all kinds of large reliefs and shadow carvings, which are widely used in the craft gift industry.

Description | Parameter |

X,Y,Z Working Area | 1300x2500x200mm |

Table Size | 1340×2850mm |

X,Y,Z Traveling Positioning Accuracy | ±0.03/300mm |

X,Y,Z Repositioning Accuracy | ±0.03mm |

Table Surface | T-slot table |

Frame | Welded Structure |

X, Y Structure | Helical Rack and Pinion Drive, |

Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

Max. Power Consumption | (Without Spindle) 3.5Kw |

Max. Rapid Travel Rate | 33000mm/min |

Max. Working Speed | 25000mm/min |

Spindle Power | 3.2KW |

Spindle Speed | 0-24000RPM(water cooling) |

Drive Motors | Stepper Motor System |

Working Voltage | AC380V/220V |

Command Language | G Code |

CNC router Features

1.With hard steel structure, fit for hard wood working, like cutting and engraving on rosewood for furniture, indoor decoration.

2.With the Vacuum holding way and dust collector, the machine is qualified for mass-producing of furniture.

3.We use the best quality parts for the woodworking cnc router .

4.The machine's body is strong, rigid, high precision, reliable and durable.

5.Imported high precision ball screw gap, smooth movement, to ensure that the machine tools high-precision.

6. Wellknown domestic brands of water cooling brushless spindle, low noise, strong cutting ability, to ensure the long time working.

7.High-performance driven motor to ensure that the woodworking cnc router high speed and accuracy.

8.Designer perfectly, select the best machine accessories, to minimize the failure rate preferred.

Regular lubrication of the rails can extend the life and accuracy of the machine, and the oil can help you fully lubricate the machine, saving time and manpower.

5. Then pack it in a fumigation free plywood box.

6. Finally fix the wooden box with steel belt.

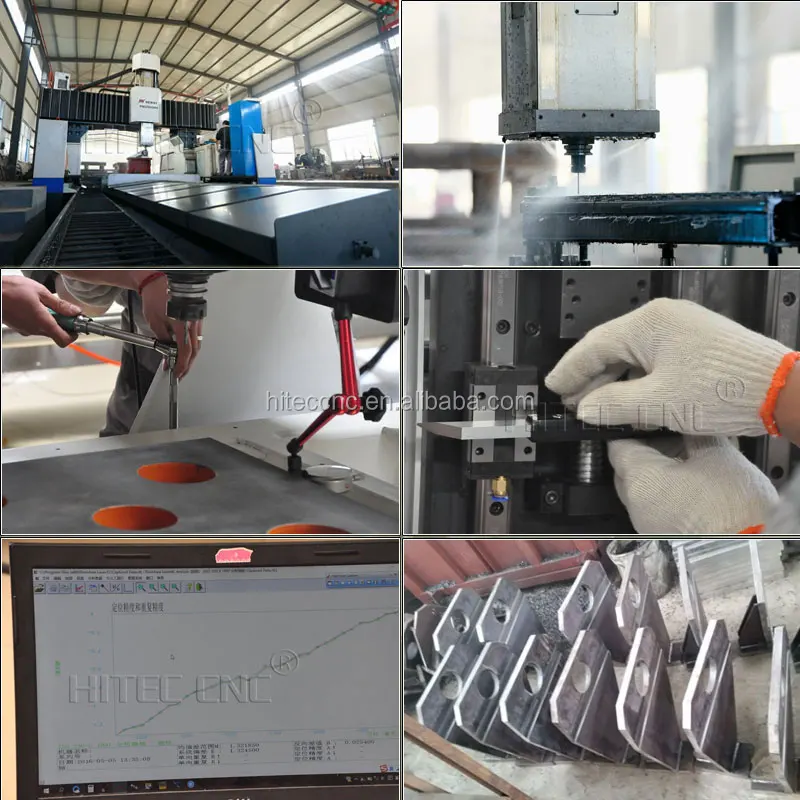

Company Information

Established in the year 2002,An ISO 9001 Firm.We are manufacturer and deverlops of the high technology machines.Hitec products are used in a wide variety of industries,markets and applications thoughout all over the world.Hitec is highly committed to offering the most advanced,capable and efficient manufacturing technology backed by unsurpassed service and support.

We offer cnc wood router,cnc laser,cnc plasma,cnc parts.

High level cnc router

Customized cnc router

Standard cnc router

All the machine parts Assembe by our machine milling and lathe machine,can be guarantee the machine precision and fast delivery time

We welcome all our buyers come to visit our factory for directly free training, our professional engineer will support you to study the machine operation.

We will supply machine operation manual, training videos and machine parameters, our engineer will supply online machine installation and training.

The customers’ technicians can keep in touch with our engineer at any time, through wechat/whatsapp/mobile phone or email, our engineer will help to solve your problems as soon as possible.

If customer need, we will send our engineer to the customers’ place to provide install and train the customer to use the

machine,our engineer will stay at customers’ place for 5-7days,customers should pay the round-trip airkets/hotels/food for our engineer.

our products can meet the needs of users to the greatest extent, and at the same time make the customer's investment play the

largest comprehensive economic benefit.

user's reasonable temporary needs;

3. Collaborate friendly with users to deliver qualified products.

Except the damage is artificial, we are responsible for offering the fittings free of charge during the guarantee period, but you

need to send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. Out of

the guaranteed period, should the parts required to be repaired or replaced, if any, the parts will be charged.

Q1: I need a cnc router, can you give me some suggestions?

Sure, please send us inquiry and tell us your processing materials,size and thickness, we will recommend you suitable model.

Q2: which kind of materials can be processed on this machine?

Most of nonmetal and metal materials, such as wood,MDF,aluminum,acrylic, aluminum and so on.

Q3: Are you a factory or trading company?

We are the manufacturer and we have over ten years factory experience .And we welcome you to visit us.

Q4: How long is the delivery time for this Professional manufacturer for cnc wood engraving engraving cutting cnc furniture machine?

For standard machines, it would be 12-15 days; For non-standard machines and customized machines according to client s specific requirements, it would be 20 to 25 days.

Q5: How should I pay for my order ?

You can do 30% prepayment at first, then we will start to make production. After finish production,shipping,then you can pay that 70% balance.