Заводская цена печь для сушки порошкового покрытия с электрической системой отопления металлического и

- Категория: Metal & Metallurgy Machinery >>>

- Поставщик: Linhai,Jin,Hai,Coating,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 2499.43 $* | 2624.15 $* |

| Aug-20-2025 | 2478.7 $* | 2602.88 $* |

| Jul-20-2025 | 2079.56 $* | 2183.76 $* |

| Jun-20-2025 | 2436.76 $* | 2558.25 $* |

| May-20-2025 | 2121.48 $* | 2227.1 $* |

| Apr-20-2025 | 2394.30 $* | 2514.78 $* |

| Mar-20-2025 | 2373.79 $* | 2492.4 $* |

| Feb-20-2025 | 2352.61 $* | 2470.8 $* |

| Jan-20-2025 | 2331.95 $* | 2448.91 $* |

Характеристики

Product Description

Powder Coating Curing Oven

This Powder coating oven used for curing the workpiece which has been spraying during the powder coating. When a thermoset powder is exposed to elevated temperature, it begins to melt, flows out, and then chemically reacts to form a higher molecular weight polymer in the surface of the workpiece.

Advantages

1. JINHAI powder coating ovens are designed to safely and efficiently cure previously applied powder coating media

2. Our energy-efficient designs save fuel and get to temperature quickly

3. Standard and custom sizes range from small Lab units to large heavy equipment ovens and conveyorized curing systems.

4. All our batch powder coating ovens feature premium 100 mm thick insulated wall and roof panels.

1. JINHAI powder coating ovens are designed to safely and efficiently cure previously applied powder coating media

2. Our energy-efficient designs save fuel and get to temperature quickly

3. Standard and custom sizes range from small Lab units to large heavy equipment ovens and conveyorized curing systems.

4. All our batch powder coating ovens feature premium 100 mm thick insulated wall and roof panels.

Specifications | Tomato&Potato | |

Model | JH-1510130D | |

Working Chamber Size (DxWxH)mm | 1500 x 1000 x1300 | |

Wall Insulation | 100% new rock wool board with 100 mm thickness | |

Heating Temperature & Time | 180° C (15-30min) Max250° C | |

Temperature Stability | < ± 3-5°C | |

Voltage/ Frequency | 110V/220V/380V (50-60hz) can be customized as local | |

Heating Source | Electric or Gas / Diesel / LPG choice as customer need | |

Motor Powder | 0.75 KW | |

Heating Power | 12 KW | |

Ventilation Performance | 805-1677 m3/h | |

Circulation / Air Flow | Vertical ,Variable through holes on the walls | |

Transportation | Moving Trolley | |

We could customized any size and specifications for you. | ||

Details Images

PLC Controller

The user-friendly PLC panel gives you an easy access to set heating temperature, time and working of fan.

Once the curing time arrive, the oven will stop heating automatically.

Simple and low fault rate.

Once the curing time arrive, the oven will stop heating automatically.

Simple and low fault rate.

Circulation Fan

The main function of circulation fan is to ensure the uniform temperature in oven chamber.

When the heating element creates hot air the circulation fan cycles the heat through entire chamber and ensures workparts to be heated evenly.

When the heating element creates hot air the circulation fan cycles the heat through entire chamber and ensures workparts to be heated evenly.

Oven Wall Materials

Oven wall interlayer material is 100mm thick rockwool board, built with heat-resistent galvanized innerwall and durable color steel outwall to form a sandwich insulation structure. This is an optimum design to maintain the temperature in oven chamber.

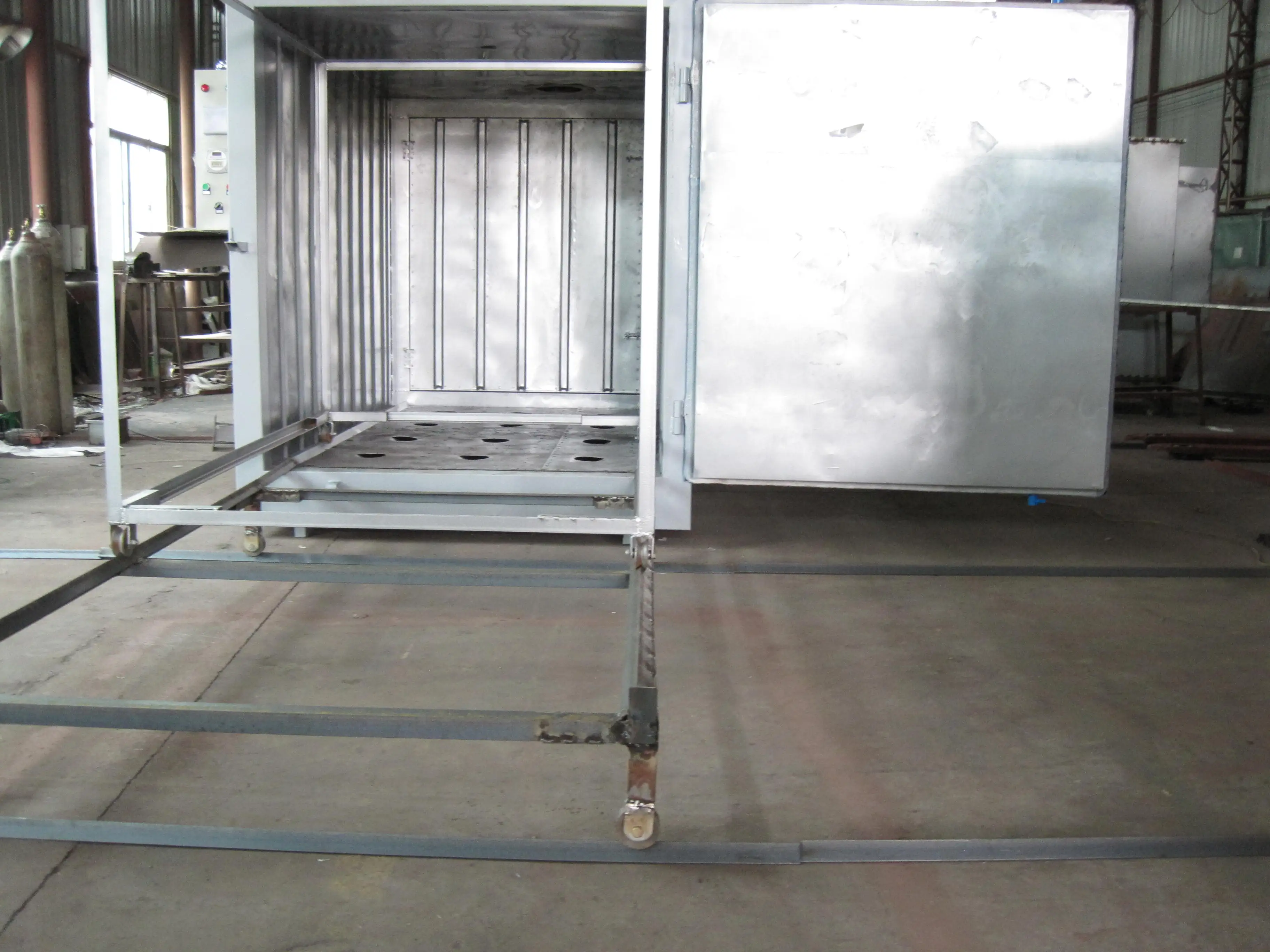

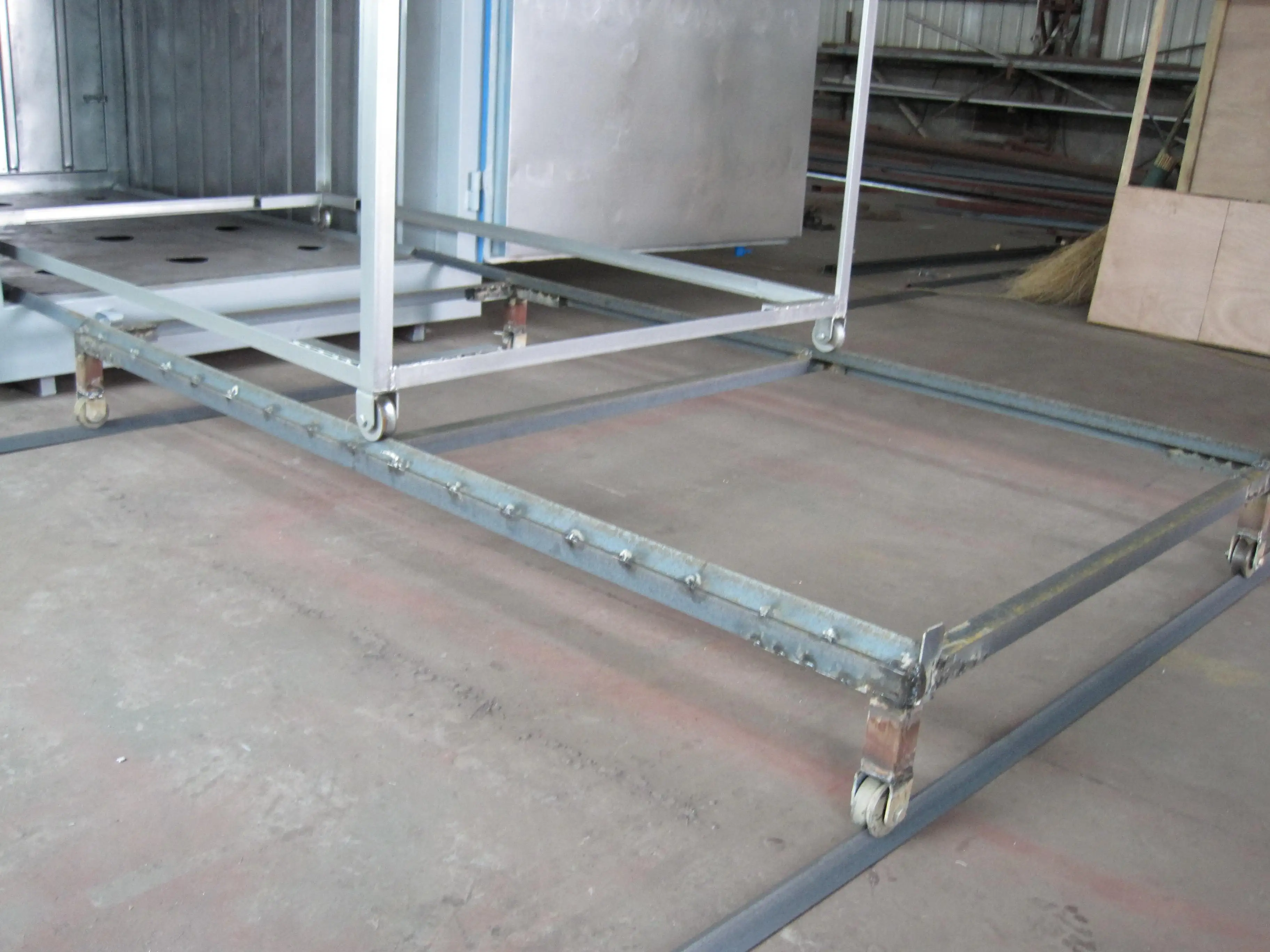

Transporting System

The trolley can design according to your metalworks,in order to conveneint for parts hanging and transport.

This transporting system will not pollute the inner chamber and workparts, ensure the clean environment in powder curing process and purity of workparts.

This transporting system will not pollute the inner chamber and workparts, ensure the clean environment in powder curing process and purity of workparts.

Company Introduction

JINAHI is professional manufacturer and export that is concerned with the design, development and production of different kinds of powder coating equipment. Covering Electrophoresis Line, Liquid Paint Line, Dip Device, Powder Coating Line, Spray Booth Oven, Powder Gun Spare Parts, Powder Coating Machine, etc. We own a development technology team with rich experience and professional sale & service team in powder coating industrial, that enable us give the best quality powder coating equipment and competitive price to customer from all over the world.

Our Services & Strength

Each piece of equipment is built to meet your specific needs. Also make sure you get the best results. Enable our customers to catch up the latest equipment, increase profits and maintain their competitiveness in the word of trade.

FAQ

Is it safe to order from JINHAI?

Yes,100% sure you are safe to order from us. JINHAI exported to many countries and we are the famous factory produce powder coating equipment more than 10 years in China.

How to delivery?

By sea for big order ,by courier for small order ,by airlines.

How to pay?

We accept the paypal ( but credit card not accepted),Western Union ,Bank transfer , money gram,etc.

Which model should I choose?

When spray specially metallic powders, according to your product shapes and the coating job details. For example, need to change colors often or only few colors, then choose the box feed unit or hopper feed unit. The small hopper unit is good for lab test or small work.

Can I customized the machines?

Yes, we are a professional team for powder coating equipments, Our technician will design for you specially according to your needs and your factory, workpiece etc information.

What should I offer if I want to customized the machine?

a. Your factory available for the equipment dimension by L x W x H

b. Your max workpiece or product weight and size by L x W x H

c. Your product surface condiation(with oil or dust?) and some pictures if possible

d. Your output capacity(for machine line)

e. Your industrial electric power in V-Phase-Hz.

Can you install for us?

Yes, we can install overseas for you. But the engineers overseas installation cost, round trip air tickets, accommodation, meals and transport charges are on the buyers.

Yes, we are a professional team for powder coating equipments, Our technician will design for you specially according to your needs and your factory, workpiece etc information.

What should I offer if I want to customized the machine?

a. Your factory available for the equipment dimension by L x W x H

b. Your max workpiece or product weight and size by L x W x H

c. Your product surface condiation(with oil or dust?) and some pictures if possible

d. Your output capacity(for machine line)

e. Your industrial electric power in V-Phase-Hz.

Can you install for us?

Yes, we can install overseas for you. But the engineers overseas installation cost, round trip air tickets, accommodation, meals and transport charges are on the buyers.

Related Products