Прямая поставка с завода трубки диаметром 90 - 150 мм машина для изготовления труб холодной

- Категория: Трубопрокатное оборудование >>>

- Поставщик: Beijing,Ron-En,Machinery,&,Integration,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 23800.93 $* | 24990.21 $* |

| Aug-16-2025 | 23600.24 $* | 24780.72 $* |

| Jul-16-2025 | 19800.76 $* | 20790.45 $* |

| Jun-16-2025 | 23200.53 $* | 24360.82 $* |

| May-16-2025 | 20200.95 $* | 21210.25 $* |

| Apr-16-2025 | 22800.86 $* | 23940.79 $* |

| Mar-16-2025 | 22600.38 $* | 23730.35 $* |

| Feb-16-2025 | 22400.55 $* | 23520.20 $* |

| Jan-16-2025 | 22200.79 $* | 23310.8 $* |

Характеристики

Tubes Cold Roll Forming Machines Rolling Mills

Product Parameters

Diagram Layout |

Coil material |

Uncoiling |

Shear&Weld |

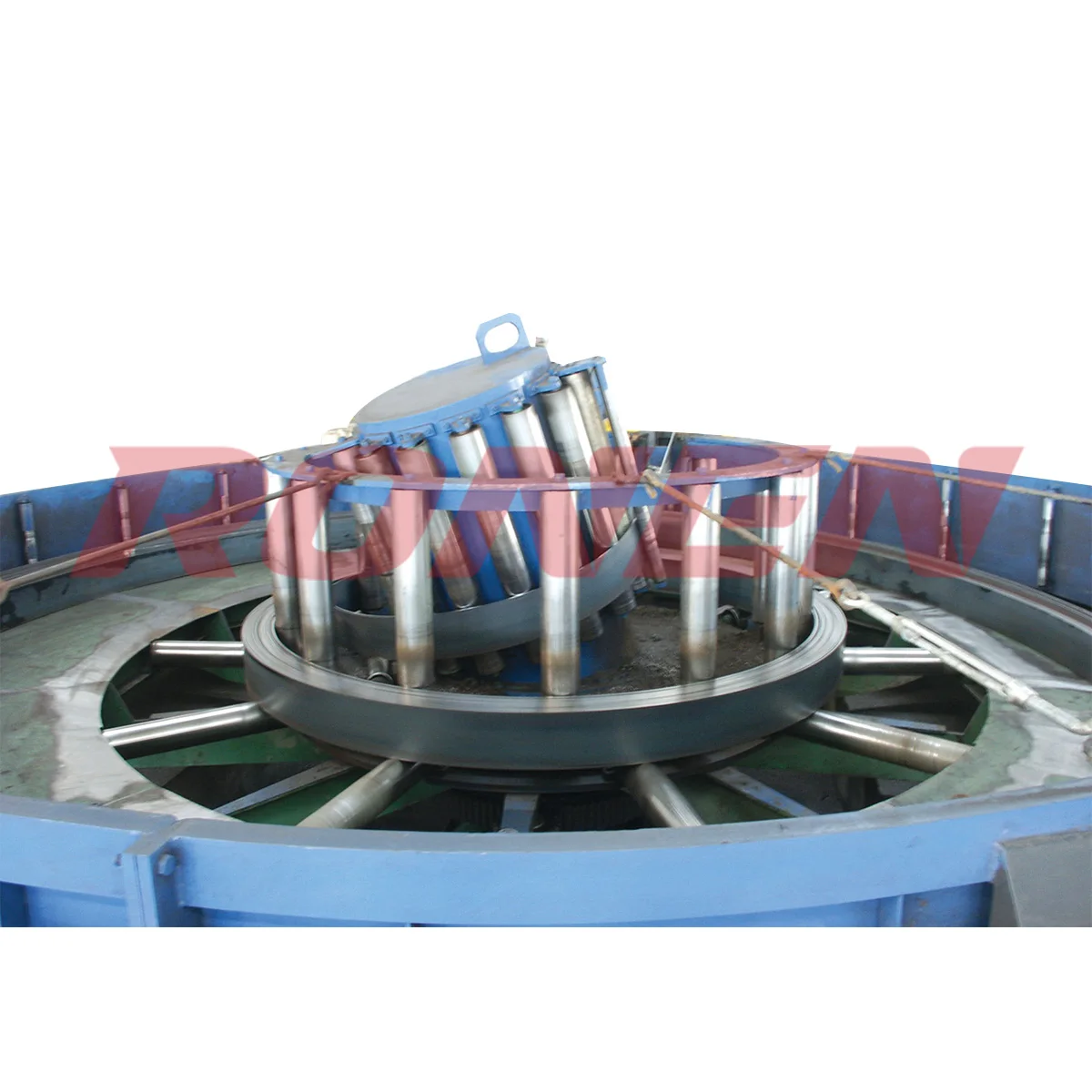

Horizontal spiral accumulator |

Forming,Welding,Cooling,Sizing—Flying saw |

Packing machine |

Product Description

General Description

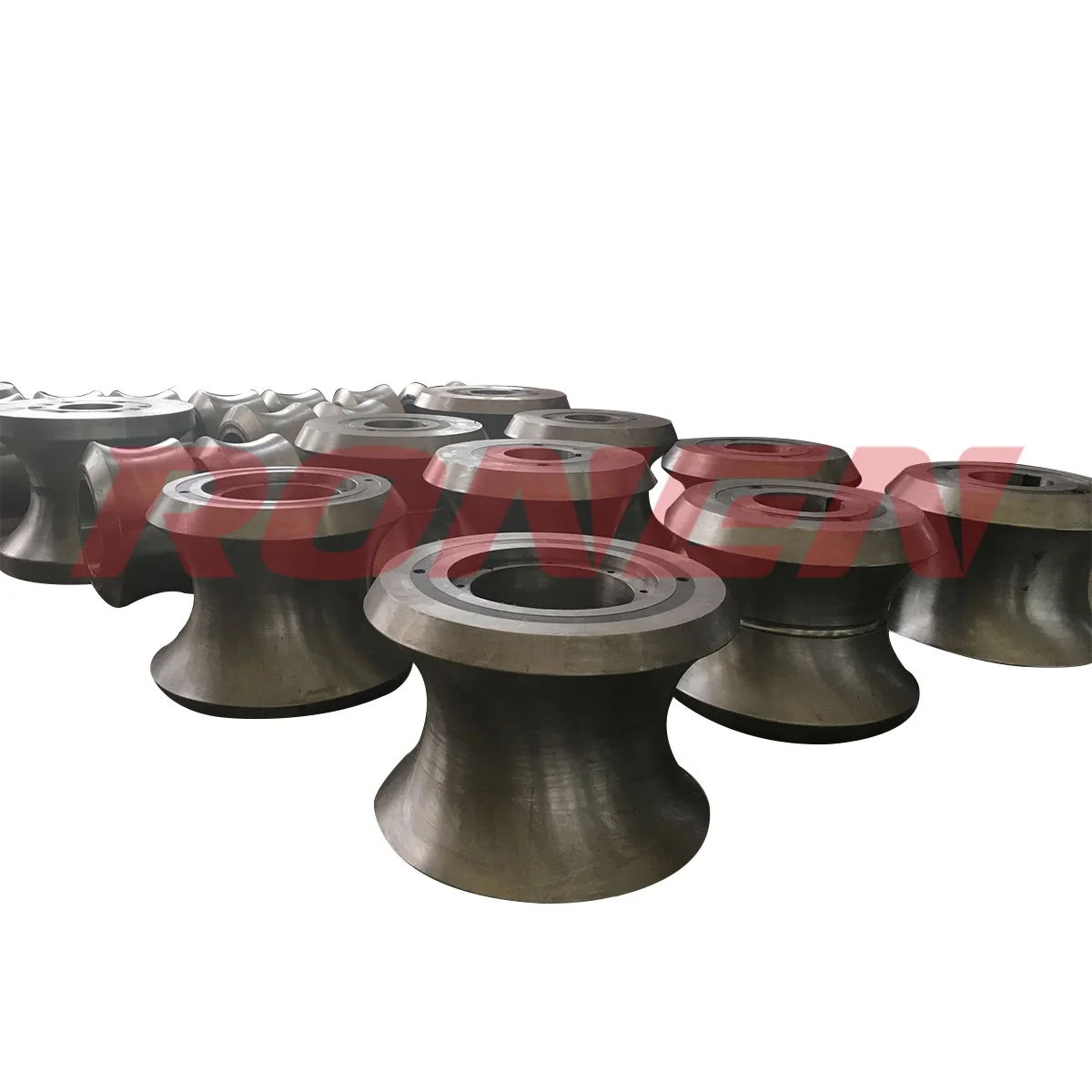

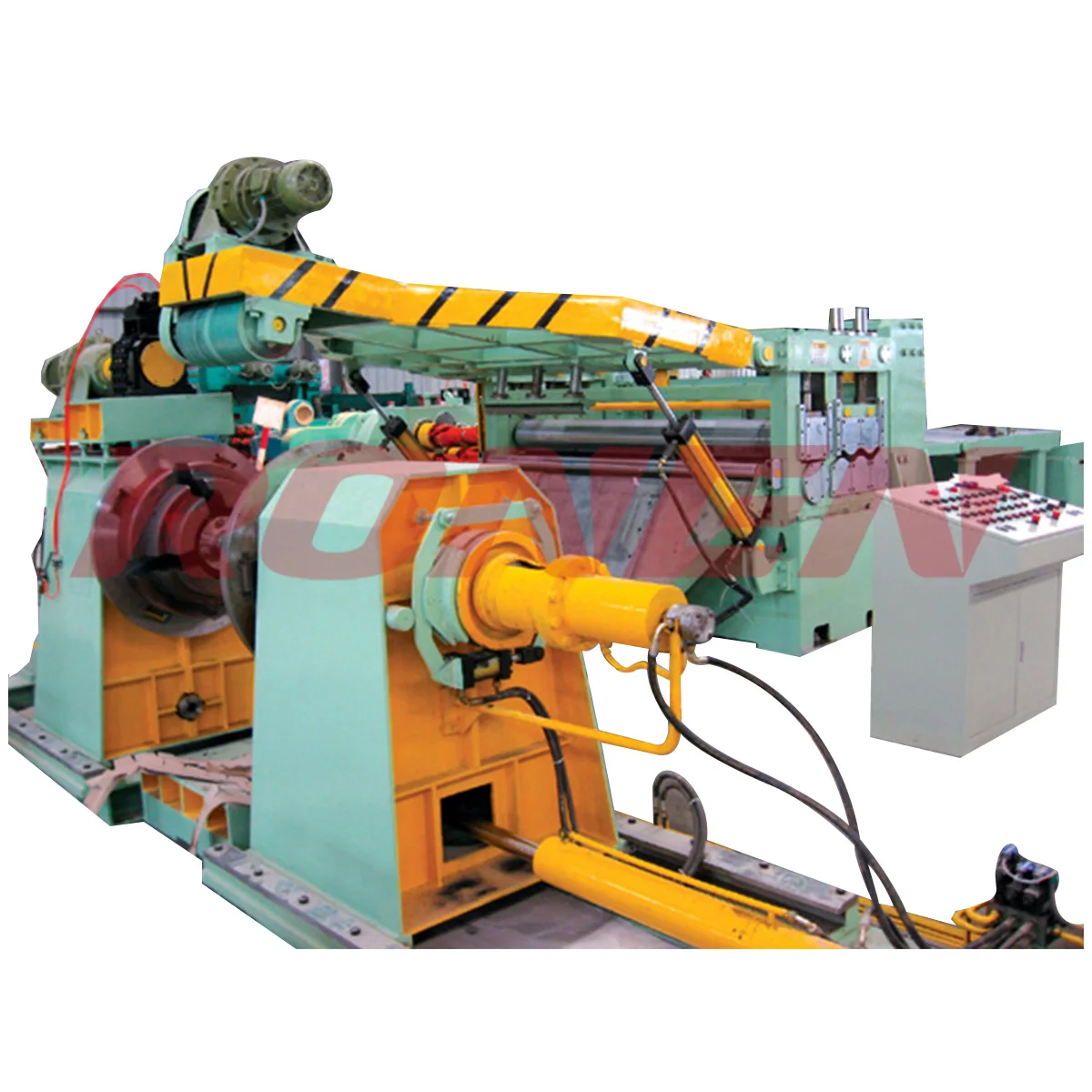

The proposed Tube Mill is a combination of equipment installed in a line for the production of High Frequency Induction Welded (HFIW) carbon steel tubes. The process involved is cold forming of carbon steel strip in circular shape, longitudinal welding, sizing, converting into specified shape and cutting to pre determined length.

Ф90 high-frequency welded tube mill line is designed to produce round tubes with diameter of Φ38.1~Φ90mm with wall thickness of 1.0~4.5mm and square/rectangular tubes of corresponding size. This line utilizes roll forming to process steel strip into various shapes. Using high frequency induction heating, this line is capable of producing section material of various diameters and sizes by squeezing weld seam together into closed shape. The products conform to BS/ASTM Standard. Adopting the advantages of the equipment of the same kind at home and abroad, each element of the line is designed with new ideas. The application of advanced technology, PLC automatic control system and British Eurasia Digital speed regulating unit ensure that the production line works reliably、operates and maintains easily. Being the best production line in China, it can also compete with the advanced ones in the world.

The proposed Tube Mill is a combination of equipment installed in a line for the production of High Frequency Induction Welded (HFIW) carbon steel tubes. The process involved is cold forming of carbon steel strip in circular shape, longitudinal welding, sizing, converting into specified shape and cutting to pre determined length.

Ф90 high-frequency welded tube mill line is designed to produce round tubes with diameter of Φ38.1~Φ90mm with wall thickness of 1.0~4.5mm and square/rectangular tubes of corresponding size. This line utilizes roll forming to process steel strip into various shapes. Using high frequency induction heating, this line is capable of producing section material of various diameters and sizes by squeezing weld seam together into closed shape. The products conform to BS/ASTM Standard. Adopting the advantages of the equipment of the same kind at home and abroad, each element of the line is designed with new ideas. The application of advanced technology, PLC automatic control system and British Eurasia Digital speed regulating unit ensure that the production line works reliably、operates and maintains easily. Being the best production line in China, it can also compete with the advanced ones in the world.

Advantages of the line: It is easy to operate,adjust and maintain with good welding seam quality and rigid machine structure.

Tube Mill Line Technical Specification

Direction of Operation: (To be confirmed by Buyer)

·Total Power: 900kW

·Compressed Air: 5m2/min Pressure: 0.4~0.7MPa

·Capacity of cooling liquid: 20t/h~30 t/h

·Tube welding speed: 20-60m/min

(Square and Rectangular Hollow Shapes are produced at lower speeds depending on side to wall thickness ratio)

·Total Power: 900kW

·Compressed Air: 5m2/min Pressure: 0.4~0.7MPa

·Capacity of cooling liquid: 20t/h~30 t/h

·Tube welding speed: 20-60m/min

(Square and Rectangular Hollow Shapes are produced at lower speeds depending on side to wall thickness ratio)

Raw Material Specification

Material: Carbon Steel, Cold or Hot Rolled pre slit strip coils of weld able grade with max. 0.2% carbon.

Material.: σb≤345Mpa σs≤520Mpa

Strip thickness: Min 1.2mm Max 4.5mm

Width of strip: 120~ 280mm

Strip Width Tolerance: ±0.1 mm

O.D of coil: φ1000-φ1800mm

I.D of coil: 508mm,(To be confirmed by Buyer)

Coil weight: 5.0T( Max)

Material.: σb≤345Mpa σs≤520Mpa

Strip thickness: Min 1.2mm Max 4.5mm

Width of strip: 120~ 280mm

Strip Width Tolerance: ±0.1 mm

O.D of coil: φ1000-φ1800mm

I.D of coil: 508mm,(To be confirmed by Buyer)

Coil weight: 5.0T( Max)

Product Specifications

· Round Tube diameter: Minφ38.1mm Max φ90mm

· Round tube wall thickness:Min1.5mm Max 4.5mm

· Square tube: Min 40x40mm, Max 70x70 mm

· Rectangle Min30x50 mm, max 40x100 mm

· Wall thickness square & rectangle tube: 1.2- 4.5 mm

· Sizing length: 4m~12m

· Cut Length Tolerance: ±3.0 mm

· Tube Thickness/Diameter Ratio:Min 0.02 Max 0.10

· Tube Standard: Apply to relevant international standard ASTM A513, ASTM A500

· Outside Diameter Tolerance: ±0.2% or ±0,15

· Round Tube diameter: Minφ38.1mm Max φ90mm

· Round tube wall thickness:Min1.5mm Max 4.5mm

· Square tube: Min 40x40mm, Max 70x70 mm

· Rectangle Min30x50 mm, max 40x100 mm

· Wall thickness square & rectangle tube: 1.2- 4.5 mm

· Sizing length: 4m~12m

· Cut Length Tolerance: ±3.0 mm

· Tube Thickness/Diameter Ratio:Min 0.02 Max 0.10

· Tube Standard: Apply to relevant international standard ASTM A513, ASTM A500

· Outside Diameter Tolerance: ±0.2% or ±0,15

Company Profile

Ronen Group is committed to designing and manufacturing of induction heating equipment, which are widely used in machinery,building materials, metallurgy, papermaking, automobile manufacturing and other fields, to fully meet the needs of steel pipe seam welding, stainless steel pipe welding, strip heating, vacuum melting, copper pipe Welding, steel pipe annealing,refrigerator tube welding, metal heat treatment, metal smelting, welding, brazing, thermal assembly and other induction heating process requirements, mainly include spring steel wires, high-strength pipe piles PC steel rods / PC bar, Prestressed steel wire,Prestressed Concrete strand, rebar, aluminum-plastic pipes, wires and cables production equipment lines.

Ronen Group domestic market share is more than 60%, and In recent years, we have exported our machines to USA, Europe, Russia, Egypt, Japan, Korea etc. more than 25 countries.

Ronen Group domestic market share is more than 60%, and In recent years, we have exported our machines to USA, Europe, Russia, Egypt, Japan, Korea etc. more than 25 countries.

Ronen will always be here for you!

Filed Application

Advantages of pipe welding equipment

2.In terms of application, welded pipes are used more and more widely, suitable for all walks of life such as agriculture and industrial production.

3.In terms of quality, the welded pipe products of the welded pipe equipment have good quality, good welding seam condition, less burr, fast speed, saving energy and cost.

4.Due to the advantages of high frequency welded pipe, such as good welding quality, fast welding speed and low power consumption, it has been widely applied and implemented.

5.Due to the large section modulus of square and rectangular tubes, welding tube equipment can withstand greater bending force, and can save a lot of metal, processing time and parts, so it is increasingly used in all aspects of industry and agriculture.

Packing & Delivery

FAQ

Contact Us

Похожие товары

Pipe machine manufacturing ERW tube production line steel pipe mill

US $80000-$90000

Steel rolling mill TY 89 carbon steel precision HF pipe making machine

US $160000-$170000

HF precision carbon steel black steel round steel pipe machine

US $90000-$95000

Pipe mill made in China TY89 HF carbon steel pipe making machine

US $160000-$170000