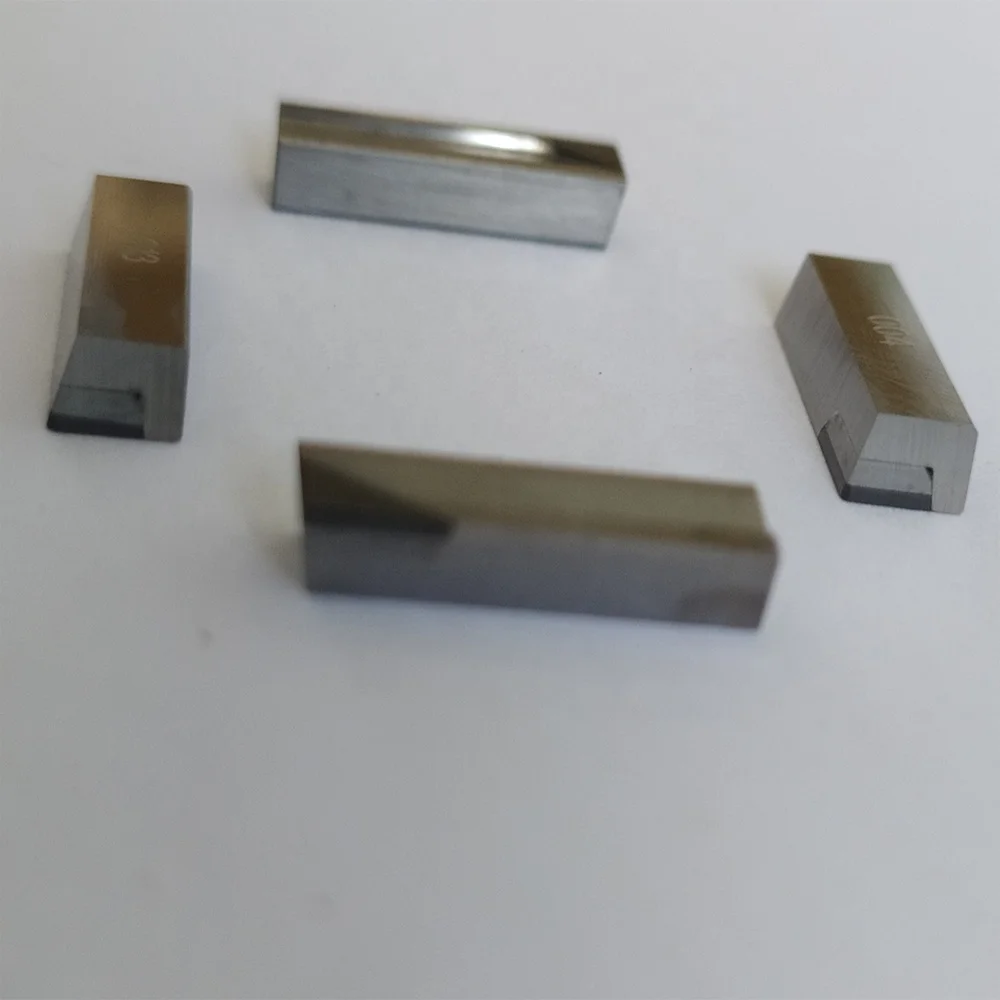

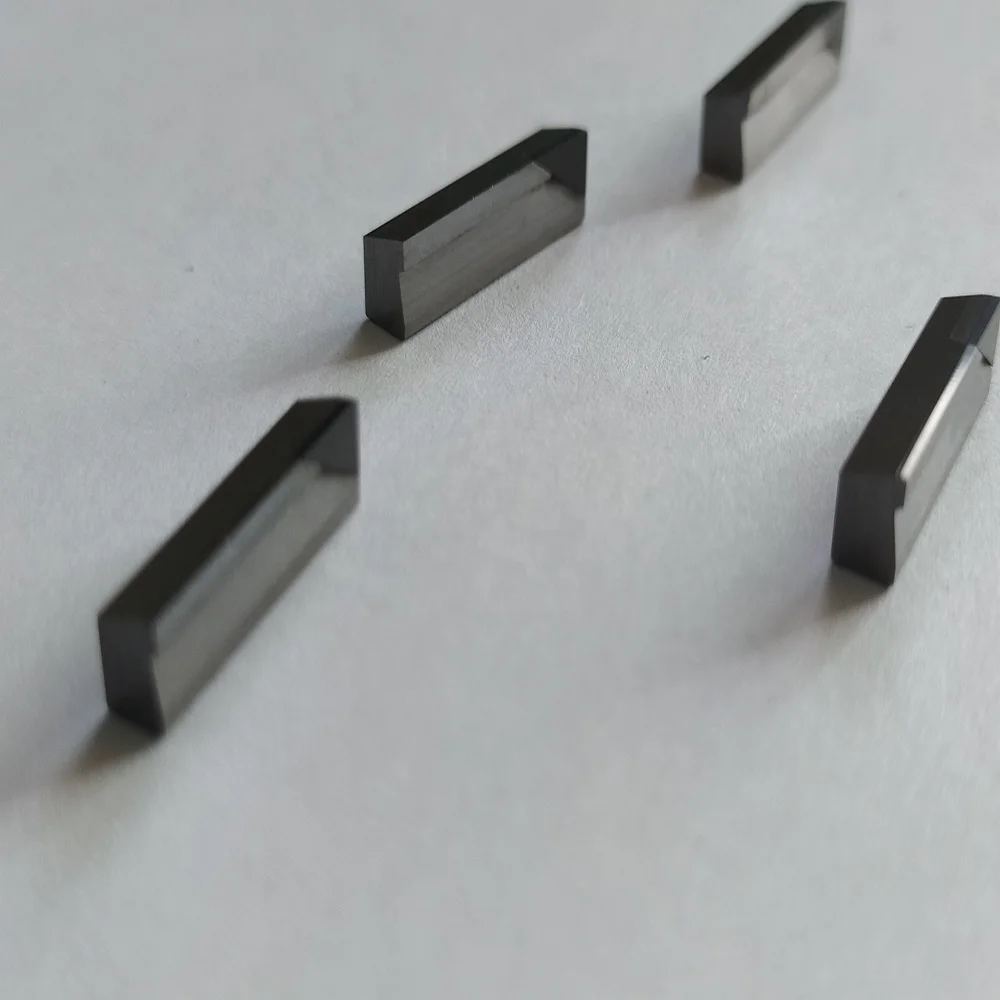

Хорошая высокая точность резки вставка 4 4-14.5L-3Y CBN Резьбовая высокого качества

- Категория: Токарный инструмент >>>

- Поставщик: Dezhou,Drillstar,Cutting,Tool,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 21.21 $* | 22.15 $* |

| Aug-20-2025 | 21.15 $* | 22.6 $* |

| Jul-20-2025 | 18.42 $* | 19.64 $* |

| Jun-20-2025 | 21.38 $* | 22.39 $* |

| May-20-2025 | 18.52 $* | 19.8 $* |

| Apr-20-2025 | 21.39 $* | 22.32 $* |

| Mar-20-2025 | 20.15 $* | 21.92 $* |

| Feb-20-2025 | 20.65 $* | 21.10 $* |

| Jan-20-2025 | 20.36 $* | 21.22 $* |

Характеристики

Product Description

The CBN insert uses a super-hard material called cubic boron nitride through a synthetic insert.

Features:

1. High hardness and wear resistance: The micro hardness of CBN single crystal is HV8000 ~ 9000, which is the second highest

hardness material known at present. The hardness of PCBN composite sheet is generally HV3000 ~ zd5000. Therefore, when used for

processing high-hardness materials, it has higher wear resistance than hard alloys and ceramics, which can reduce dimensional

deviation or dimensional dispersion in the processing of large parts, and is especially suitable for equipment with a high degree

of automation, which can reduce the change The knife adjusts the auxiliary time, so that its efficiency can be fully exerted.

2. It has high thermal stability and high temperature hardness:

The heat resistance of CBN can reach 1400 ~ 1500 ℃. The hardness at 800 ℃ is the normal temperature hardness of Al2O3 / TiC

ceramics. Therefore, when the cutting temperature is high, the processed material will be softened and the hardness difference

between the tool and the tool will increase. , It is beneficial to the cutting process, and has little effect on the life of the

tools weight.

1. High hardness and wear resistance: The micro hardness of CBN single crystal is HV8000 ~ 9000, which is the second highest

hardness material known at present. The hardness of PCBN composite sheet is generally HV3000 ~ zd5000. Therefore, when used for

processing high-hardness materials, it has higher wear resistance than hard alloys and ceramics, which can reduce dimensional

deviation or dimensional dispersion in the processing of large parts, and is especially suitable for equipment with a high degree

of automation, which can reduce the change The knife adjusts the auxiliary time, so that its efficiency can be fully exerted.

2. It has high thermal stability and high temperature hardness:

The heat resistance of CBN can reach 1400 ~ 1500 ℃. The hardness at 800 ℃ is the normal temperature hardness of Al2O3 / TiC

ceramics. Therefore, when the cutting temperature is high, the processed material will be softened and the hardness difference

between the tool and the tool will increase. , It is beneficial to the cutting process, and has little effect on the life of the

tools weight.

Especially suitable for the auto part such as bearing race , processing material is powder metallurgy

Specification

TYPE | INSERT LENGTH | WIDTH | THICKNESS |

4.4-14.5L-3Y | 14.5MM | 4.4MM | 3MM |

4.4-15.88-3T | 15.88MM | 4.4MM | 3MM |

Packing & Delivery

five pieces for one plastic box with foam inner to avoid the damager for this special insert , outer packing with standard carton ,wrapped with foam , prevent the damage.

Recommend Products

Shipping

Company Profie

company brief introduction

Dezhou Drillstar Cutting Tool Co., Ltd is a manufacturer and exporter of gun drills, gun drilling machine, and machine accessories. We also distribute cutting oils, cutter grinder, oil spray pump complete kit on the deep hole drilling field. We are engaged in designing products in compliance with international quality standards with best configuration to offer excellent productivity and quality to clients. Started in the year 2010, we have occupied a strong foothold in the domestic market and have also acquired many clients in South East Asia, Europe and others. As an one-Stop solution provider for deep hole cutting tools. widely meet the need of different

clients.

clients.

FAQ

1. Do you provide free samples for testing?

Our advantage is making the non-standard insert for different application ,so it is a pity that we can not provide samples for free.

2. Can you provide all sizes?

We can provide all sizes can be made by your need.

3.Do you provide free samples for testing?

Answer: Yes, we would like provide you samples free in cost.

4. Will you attend International Exhibition?

Yes, we had attended exhibitions in many countries, such as Turkey, India, Thailand, Vietnam, Taiwan, etc. We have been to

Indonesia in 2018 as usual.

Our advantage is making the non-standard insert for different application ,so it is a pity that we can not provide samples for free.

2. Can you provide all sizes?

We can provide all sizes can be made by your need.

3.Do you provide free samples for testing?

Answer: Yes, we would like provide you samples free in cost.

4. Will you attend International Exhibition?

Yes, we had attended exhibitions in many countries, such as Turkey, India, Thailand, Vietnam, Taiwan, etc. We have been to

Indonesia in 2018 as usual.