Ножная педаль автомат для

- Категория: Отрезной станок >>>

- Поставщик: Wincoo,Engineering,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.15 $* | 0.77 $* |

| Aug-19-2025 | 0.24 $* | 0.74 $* |

| Jul-19-2025 | 0.84 $* | 0.65 $* |

| Jun-19-2025 | 0.38 $* | 0.30 $* |

| May-19-2025 | 0.74 $* | 0.43 $* |

| Apr-19-2025 | 0.70 $* | 0.87 $* |

| Mar-19-2025 | 0.54 $* | 0.97 $* |

| Feb-19-2025 | 0.66 $* | 0.74 $* |

| Jan-19-2025 | 0.18 $* | 0.59 $* |

Характеристики

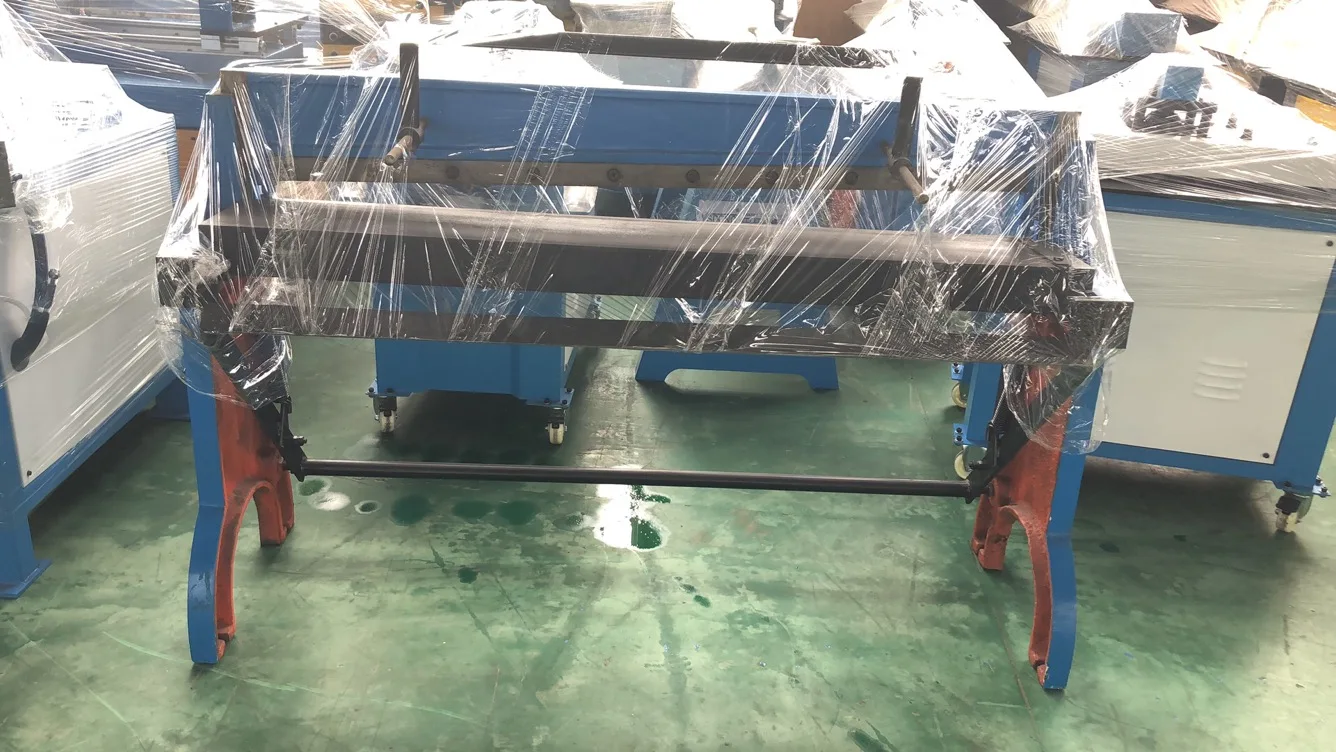

FOOT Pedal Cutting Machine

Dear users:

When you have purchased the mechanical products produced by our factory, please note the following:

1) If you find that the accessories do not match the packing list or have questions in use, please contact our after-sales service department in time, please indicate the product model, specification and factory number.

2) To help you better understand this machine, please read the instructions carefully before installation and use. Must understand the installation, adjustment, operation and other matters in the specification.

3) When our factory produces machinery, all carry on the whole machine assembly and debugging work on the horizontal platform. Therefore, after the customer has been installed, it must be adjusted before it can be debugged.

4) After adjusting the mechanical products, please check the clearance to avoid bite knife or other condition.

5) For the sake of safety, the hydraulic oil of our factory has been pulled out after the inspection of the hydraulic products.

6) More attention should be paid to safety measures and electrical installation. For machine damage and personal injury caused by improper operation or improper use and maintenance in the course of use, the user shall bear the responsibility for the machine damage and personal injury caused by improper operation or improper use and maintenance.

Catalogue

I. Instructions……………………………………........………1

II. Outside drawing …………………………………………2

III. Use and adjustment of machine……........………2

IV. Lubrication of machine…………………......…………3

V. Machine maintenance and safety technical instructions …………………3

I. Instructions

Q11 series foot shearing adopts the whole welding frame, sliding guideway and pull spring structure, which has the characteristics of beautiful appearance, novel structure, light operation, no power supply, convenient movement and so on. Widely used in motor, electrical appliances, hardware, construction, decoration and other industries of metal sheet human shear, can cut all kinds of carbon steel plate, silicon steel sheet, tinplate, copper and aluminum, plastic, insulated plate and so on.

This machine is composed of upper and lower tool holder, side plate, control mechanism and other main parts. When in operation, step down the pedal, drive the upper tool holder through the connecting rod, make the upper tool holder move in a straight line from top to bottom under the action of chute, complete the shear action, relax the foot after the shearing, relax the foot, return to the highest point under the action of reset spring, and wait for the next shear.

II. Outside drawing

Main parameters

Model | Cutting thickness(mm) | Cutting width(mm) | Shear angle | Weight (kg) | L*W*H(mm) |

Q11-1*1000 | 1.0 | 1000 | 1°30' | 130 | 1200*650*950 |

Q11-1*1300 | 1.0 | 1300 | 1°30' | 150 | 1500*650*950 |

Q11-1*1500 | 1.0 | 1500 | 1°30' | 180 | 1800*650*950 |

Q11-1*2000 | 1.0 | 2000 | 1°30' | 220 | 2100*650*950 |

III. Use and adjustment of machine

Knife clearance adjustment:

Step on the pedal, make the upper tool holder outside the lower dead point position, loosen the compression screw located on both sides of the left and right sliding slot plate, adjust the movement of the upper tool holder before and after, measure the full length edge clearance with the plug ruler, and then lock the adjustment nut and close the compression screw when the required value is reached evenly. If the edge is not straight, the fastening screw can be adjusted before and after the knife, so that the edge is straight.

Recommended cutting edge clearance value (sheet material 500MPa) unit: mm

IV. Lubrication of machine

Nu | Name | lubricant | Refueling cycle |

1 | Chute board | Lithium-based lipids | 7 days |

2 | Pin roll | N32 Mechanical Oil | 30 days |

3 | Shaft bearing | Lithium-based lipids | 90 days |

V. Machine maintenance and safety technical instructions

1. This machine operator should be familiar with the mechanism and performance of this machine, and can operate in strict accordance with the relevant regulations in GB 6077< Operation rules for the Safety of Shear Machinery >.

2. When the multi-person operation should coordinate with each other, strictly forbid to extend the hand, the tool extends to the scissors, and beware the sharp edge of the sheet metal scratches the finger;

3. It is prohibited to cut super thick and spring plate and other high strength plates!

Vulnerable parts list

Nu | Name | Drawing number | Material | Pcs |

1 | top knife | 0001 | T8 | 1 |

2 | bottom knife | 0002 | T8 | 1 |