Northstar FS1 #400 HDD сверлильный стержень используемый для Hdd Rig D20 * 22

- Категория: Mining Machine Parts >>>

- Поставщик: North,Star,(Beijing),Machinery,&,Drilling,Tools,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.56 $* | 0.3 $* |

| Aug-19-2025 | 0.42 $* | 0.67 $* |

| Jul-19-2025 | 0.2 $* | 0.20 $* |

| Jun-19-2025 | 0.61 $* | 0.94 $* |

| May-19-2025 | 0.99 $* | 0.79 $* |

| Apr-19-2025 | 0.83 $* | 0.14 $* |

| Mar-19-2025 | 0.55 $* | 0.36 $* |

| Feb-19-2025 | 0.28 $* | 0.66 $* |

| Jan-19-2025 | 0.76 $* | 0.70 $* |

Характеристики

Product Description

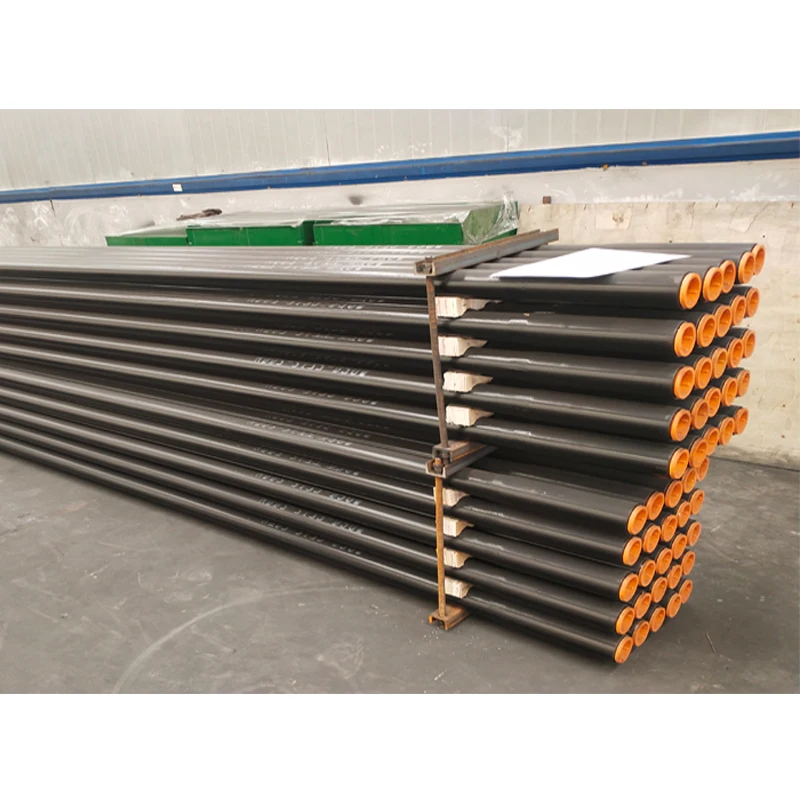

HDD Drill Rod Compatible With Ditch Witch HDD rigs

Specification

RIG COMPATIBILITY | THREAD | LENGTH (MM) | PIPE OD (MM) | WEIGHT (KG) |

JT2720 | DW1.94 | 3000 | 60 | 34 |

JT20 | DW1.94 | 3000 | 52 | 28 |

JT2720M1,JT3020M1 | DW2.11 | 3000 | 60 | 36 |

JT25/30 | DW2.11 | 3000 | 60 | 34 |

JT4020 | DW2.40 | 4500 | 73 | 65 |

JT4020M1 | DW2.59 | 4500 | 76 | 76 |

JT7020M1,JT8020M1, JT100M1 | DW3.27 | 4500 | 89 | 98 |

More details please feel free to contact with us.

Quality Control

Our quality team’s work begins by ensuring a consistently high standard of raw material: checking every batch on delivery against the technical team’s strict criteria for dimensional accuracy and steel chemistry. Once approved for production, every item of material is issued a work number that allows us to track it through every subsequent step of the manufacturing process. The completed product is finally issued and stamped with a serial number that enables 100%

traceability of all that manufacturing data.

traceability of all that manufacturing data.

Consistent raw material quality & 100% traceability

Zero-flaw visual and physical inspection standard

.

S135 mechanical quality testing

Complete control of heat treatment

and data traceability

and data traceability

Upset Forging

Packing & Delivery

Company Profie

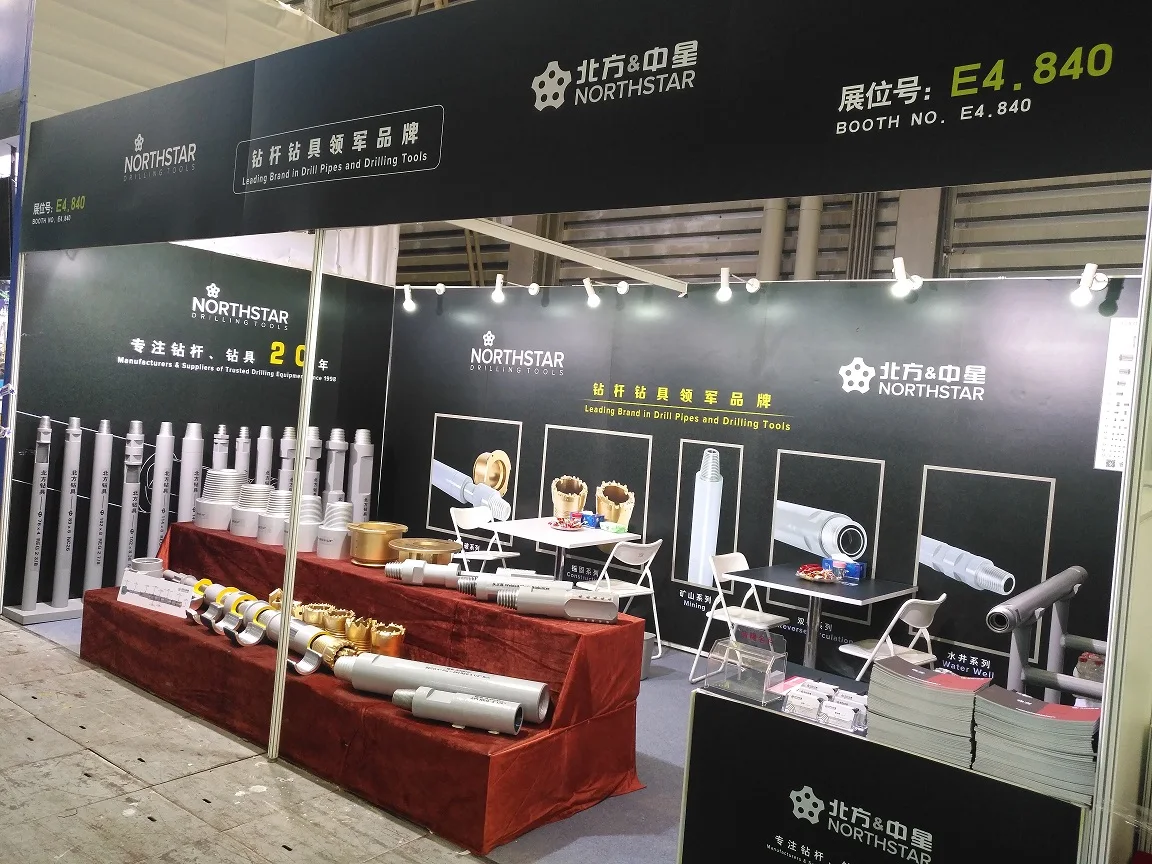

North Star is well known in HDD tools, DTH tools, top hammer, rotary tools, ...and so on. We are serving the drilling industry in mining, construction and energy with different application. Our vision is to be market leader in related industry with innovation and customer orientation.

Northstar has 20 year's experience in manufacturing drill pipe for the Chinese and international markets. Sales in 2018 are approaching 250,000 pipes, and we are to lift capacity to well in excess of 300,000 pipes in 2019.

We stand by our products. Our aim is 100% customer satisfaction and to that end we take every enquiry and every question with equal seriousness. Our multilingual, muti-cultural management team prioritizes smooth, effective communication.

Northstar has 20 year's experience in manufacturing drill pipe for the Chinese and international markets. Sales in 2018 are approaching 250,000 pipes, and we are to lift capacity to well in excess of 300,000 pipes in 2019.

We stand by our products. Our aim is 100% customer satisfaction and to that end we take every enquiry and every question with equal seriousness. Our multilingual, muti-cultural management team prioritizes smooth, effective communication.

We are dedicated to continuous improvement of all production and delivery processes. No pipe is released to market without a quality report compliance with all destructive and non-destructive testing critiria. We aim to achieve 100% traceability to ensure our partners and customers can use North Star products with complete confifidence.

Exhibition

Related Products

Why Choose Us

THE NORTH STAR TEAM IS AT YOUR SERVICE

North Star has 20 years’ experience in manufacturing drill pipe for the Chinese and international markets. Sales in 2018 are approaching 250,000 pipes, and we are pursuing a US$4 million expansion and upgrading program that will lift

capacity to well in excess of 300,000 pipes in 2019.

capacity to well in excess of 300,000 pipes in 2019.

2.INTERNATIONAL SERVICE CULTURE & PRODUCT SUPPORT

We stand by our products. Our aim is 100% customer satisfaction and to that end we take every enquiry and every question with equal seriousness. Our multilingual, multicultural management team prioritizes smooth, effective communication.

We work together with our partners and end-users to help ensure they get maximum value from every product. If necessary, we send staff members and engineers on site for further study and training. All our products are fully

guaranteed against defects in materials or workmanship.

We work together with our partners and end-users to help ensure they get maximum value from every product. If necessary, we send staff members and engineers on site for further study and training. All our products are fully

guaranteed against defects in materials or workmanship.

3.QUALITY MANAGEMENT

Our quality team’s work begins by ensuring a consistently high standard of raw material: checking every batch on

delivery against the technical team’s strict criteria for dimensional accuracy and steel chemistry. Once approved

for production, every item is issued a work number that allows us to track it through each subsequent step of the

manufacturing process.

We are dedicated to continuous improvement of all production and delivery processes. No pipe is released to market without a quality report verifying compliance with all destructive and non-destructive testing criteria. We aim

to achieve 100% traceability to ensure our partners and customers can use North Star products with complete confidence.

delivery against the technical team’s strict criteria for dimensional accuracy and steel chemistry. Once approved

for production, every item is issued a work number that allows us to track it through each subsequent step of the

manufacturing process.

We are dedicated to continuous improvement of all production and delivery processes. No pipe is released to market without a quality report verifying compliance with all destructive and non-destructive testing criteria. We aim

to achieve 100% traceability to ensure our partners and customers can use North Star products with complete confidence.

4.CONTINUOUS INVESTMENT

North Star is investing US$4 million in 2018 and 2019 as we upgrade equipment and expand production into a new

12,000-square meter workshop, complete with a loading bay that will allow containerization of export product by our

own dedicated team. In 2018 we have already installed a dedicated tool joint forge and heat treatment line, enabling both cost savings and more effective in-house quality control.

12,000-square meter workshop, complete with a loading bay that will allow containerization of export product by our

own dedicated team. In 2018 we have already installed a dedicated tool joint forge and heat treatment line, enabling both cost savings and more effective in-house quality control.

5.TRUST IN PARTNERSHIPS

North Star believes in long-term, mutually supportive business relationships. We are totally committed to working

together with our partners: making sure we match the right product with the right project - and at the right price.

together with our partners: making sure we match the right product with the right project - and at the right price.

Похожие товары

Буровое долото из карбида вольфрама 8 1/2 "IADC 537 637 tci tricone

US $200.00-$520.00

Буровая установка поворотного типа

US $100.00-$200.00