Linbel падающий пленочный испаритель промышленный Cbd из нержавеющей

- Категория: Evaporator >>>

- Поставщик: Shanghai,Linbel,Instrument,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-15-2025 | 12699.28 $* | 12953.58 $* |

| Jul-15-2025 | 10299.74 $* | 10505.88 $* |

| Jun-15-2025 | 12499.6 $* | 12749.94 $* |

| May-15-2025 | 12399.81 $* | 12647.90 $* |

| Apr-15-2025 | 9899.29 $* | 10097.66 $* |

| Mar-15-2025 | 12199.48 $* | 12443.40 $* |

| Feb-15-2025 | 12099.46 $* | 12341.46 $* |

| Jan-15-2025 | 11999.7 $* | 12239.82 $* |

Характеристики

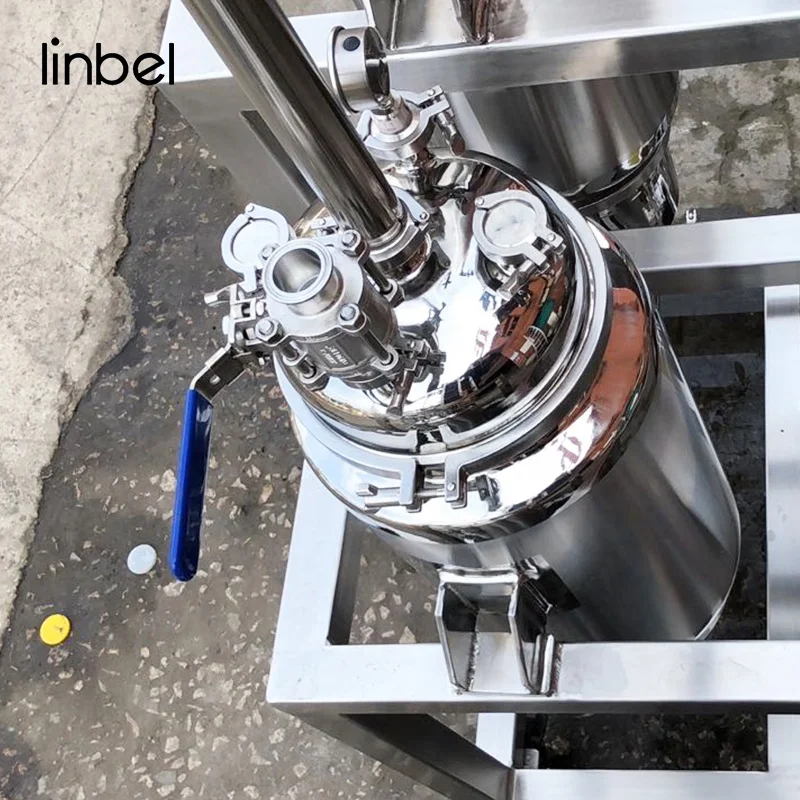

Linbel Falling Film Evaporator Industrial Falling Film Evaporator Cbd Stainless Steel Falling Film Evaporator

Falling film evaporation is to add the material liquid from the upper tube box of the heating chamber of the falling film evaporator, and distribute it evenly into the heat exchange tubes through the liquid distribution and film forming device. Under the action of gravity, vacuum induction and air flow, it becomes a uniform film. Flow from top to bottom. During the flow process, it is heated and vaporized by the heating medium in the shell side. The generated steam and liquid phase enter the separation chamber of the evaporator. After the vapor and liquid are fully separated, the steam enters the condenser for condensation (single-effect operation) or enters the next-effect evaporator as The medium is heated to achieve multi-effect operation, and the liquid phase is discharged from the separation chamber.

| Project | One effect evaporator | Condenser |

| Material name | Alcohol solution | --- |

| PH value | / | --- |

| Discharge method | First effect output | --- |

| Total feed | 300kg/h | |

| Rated evaporation | 200kg/h | |

| Raw steam consumption | 200kg/h(Saturated Vapor) | |

| Steam consumption ratio | Each ton of water evaporated requires ≤1100kg steam | |

| Raw steam temperature (℃) | 105±2 vapor phase | --- |

| Secondary steam temperature of each effect (℃) | 70±2 vapor phase | 70±2 vapor phase |

| Temperature of each effect material liquid (℃) | 75±2vapor phase | 45±2vapor phase |

| Vacuum degree of each effect (-MPa) | ~0.05 | ~0.090 |

| The boiling point of each effect material liquid increases (℃) | ~5 | --- |

| Temperature loss of each effect (℃) | 2 | --- |

| Heat loss of each effect (%) | 0.08 | --- |

| Effective heat transfer temperature difference of each effect (℃) | 30 | --- |

| Circulation type of each effect evaporator | Falling film circulation | --- |

| Heat transfer coefficient of each effect (W/m2.k) | 1150 | --- |

| Feed in/out of material liquid (kg/h) | 300/100 | |

| Concentration of incoming and outgoing materials (%) | 13/40 | |

| Design heating area (m2) | 9.5 | --- |

| Design condensing area (m2) | 11 | --- |

| Recycled alcohol (kg/h) | ~200kg/h |

Shanghai Linbel Instrument Co., Ltd. was founded in Shanghai, which is a professional supplier of chemical and pharmaceutical equipments with many years’ experience. We have a professional team including experienced consultants, engineers, quality inspection team and shipping company to provide reliable quality and professional service for our customers. We always expand our production line, we produce recirculating chiller, rotary evaporator, reactor, dynamic temperature control system, molecular distillation system, short path turnkey, oil circulating heater and centrifuge machine etc. We will design and customize suitable machines to our customers according to their requirments and also provide OEM and ODM service for them.