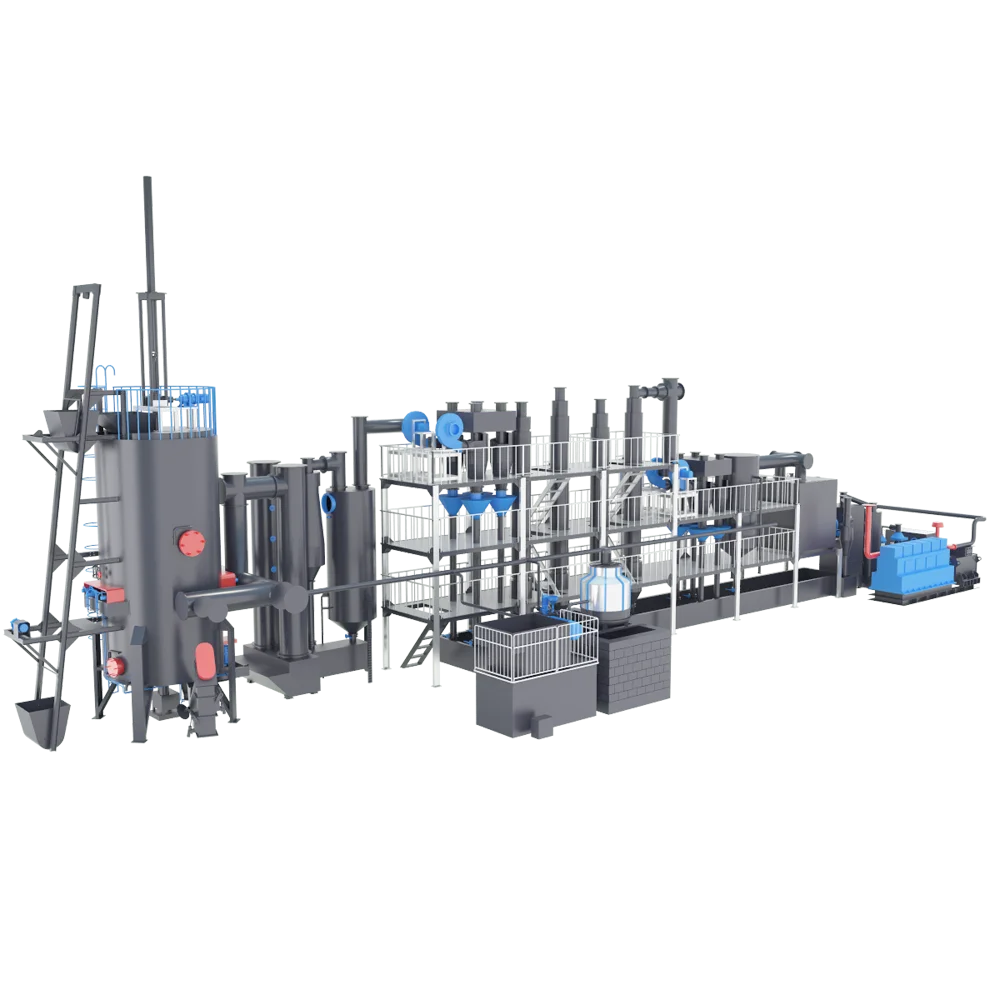

Оборудование для генерации биомассы древесных чипов/опилок/гранул/навоза

- Категория: Electricity Generation >>>

- Поставщик: Henan,Haiqi,Environmental,Protection,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 340340.94 $* | 357357.0 $* |

| Aug-16-2025 | 337480.15 $* | 354354.53 $* |

| Jul-16-2025 | 283140.82 $* | 297297.31 $* |

| Jun-16-2025 | 331760.7 $* | 348348.7 $* |

| May-16-2025 | 288860.93 $* | 303303.15 $* |

| Apr-16-2025 | 326040.98 $* | 342342.88 $* |

| Mar-16-2025 | 323180.90 $* | 339339.55 $* |

| Feb-16-2025 | 320320.53 $* | 336336.55 $* |

| Jan-16-2025 | 317460.45 $* | 333333.62 $* |

Характеристики

Biomass fuel Features

Fuel Typle: Wood chip,Herbals,Straw,Rice Husk,Coconut shells.

Material size: 30-50mm

Moisture content: 10-15%

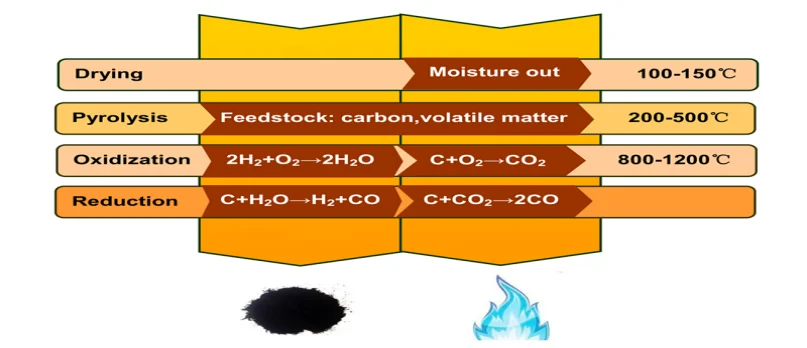

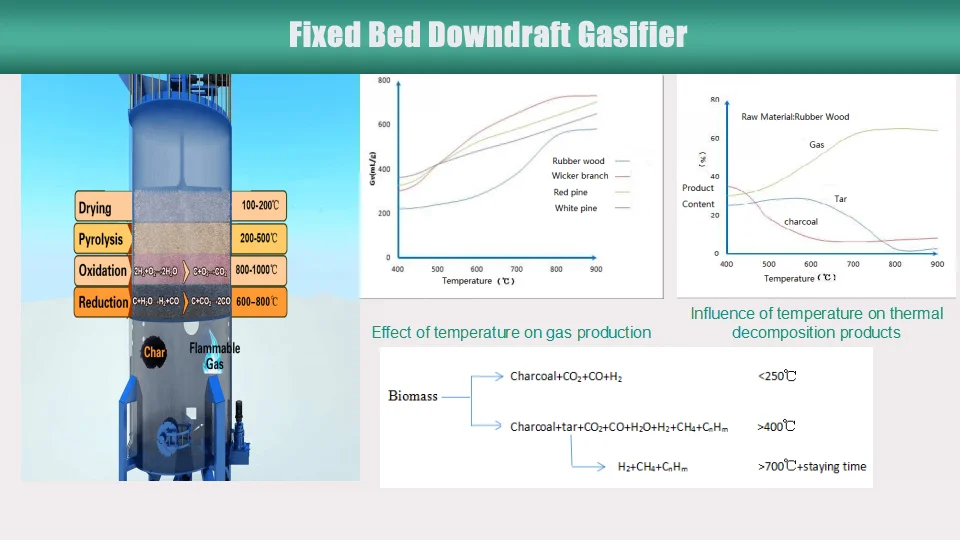

Principle of pyrolysis and gasification

Biomass gasification refers to the thermochemical process of converting biomass fuels into flammable gases. In this process, water vapor, free oxygen, or bound oxygen reacts with the carbon in the fuel to form a combustible gas. Biomass gasification process is more complex and the gasification reaction conditions are also different. However, all the gasification reaction processes basically include the processes of biomass drying, pyrolysis, oxidation and reduction.

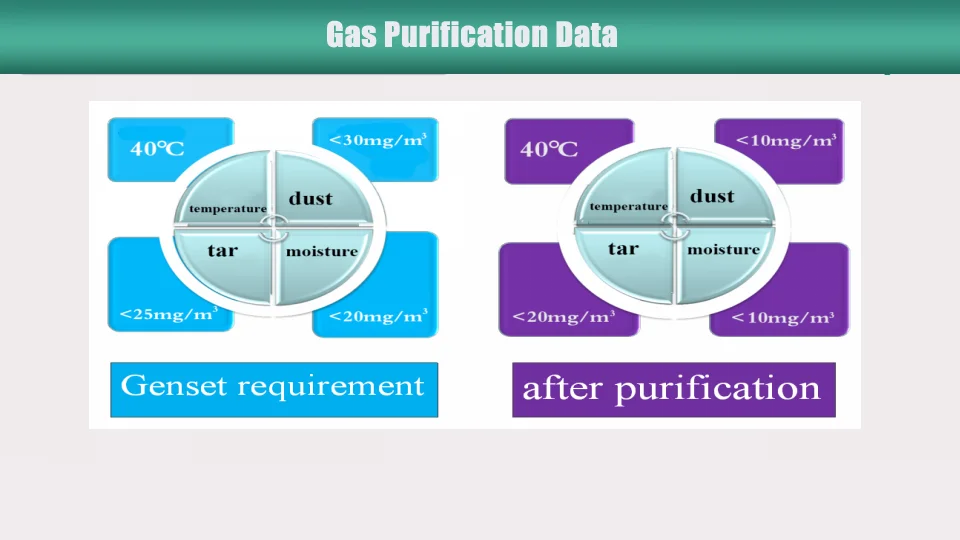

Purification Process

Spraying tower :Spray cooling, small amount of water, instant vaporization, no sewage, sedimentation of large dust particles, quickly reduce the temperature of the syngas.

Tube condenser:Indirect heat exchange with circulating water reduces the temperature of the mixture and further liquefies the tar.

Quadruple cyclone:Using the principle of high-speed centrifugal separation to effectively settle the liquefied tar.

Tube cyclone separator:Combination of tube condensation and cyclone dust removal, further dust reduction and tar removal.

Quadruple cyclone:Using centrifugal separation principle to further remove tar.

Tube condenser:Cold water heat exchange, reduce the temperature of the mixture, continue to liquefy the tar and reduce it.

Box filters:Efficient filler, modular arrangement, remove small particles of dust and tar in the mixture.

Tube condenser:The last step is to reduce the temperature and ensure that the temperature of the gas mixture reaches the internal combustion engine.

Rotary filter:The unique structure of rotary vane filter can effectively remove water vapor and partial tar from the gas mixture.

Gas filter:The use of a customized air filter can effectively intercept small particles, so that the flammable gas entering the engine can reach the standard, and the customized filter can be used repeatedly.

Buffer tank:The equipment is placed on the front of the generator set, mainly to buffer and temporarily store part of the combustible gas, so as to reduce the impact of the fluctuation of the gasification system on the generator set.

Syngas Gas component table

| Test Report | No. | Test item | Test result | |

| 1 | Component | O2 | 2.30% |

| 2 | N2 | 48% | ||

| 3 | CH4 | 5.00% | ||

| 4 | CO | 10.50% | ||

| 5 | CO2 | 21.30% | ||

| 6 | H2 | 11.80% | ||

| 7 | CMHN | 1.10% | ||

| 8 | Caloric value | 5.188MJ/m³ | ||

| 9 | Relative density | 97.32% | ||

Cooperation Method

1.Equipment Purchase and Sal.

2.Equipment Agency or Agency Sales.

3.Contract energy management.

Our service: