Yi Long многофункциональные полностью автоматический мешок с застежкой-молнией готовых Ротари Машина для упаковки пищевых продуктов дойпак упаковочная

- Категория: Многофункциональные упаковочные машины >>>

- Поставщик: Qingdao,Yilong,Packaging,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.37 $* | 0.89 $* |

| Aug-16-2025 | 0.98 $* | 0.8 $* |

| Jul-16-2025 | 0.85 $* | 0.4 $* |

| Jun-16-2025 | 0.92 $* | 0.91 $* |

| May-16-2025 | 0.37 $* | 0.41 $* |

| Apr-16-2025 | 0.48 $* | 0.50 $* |

| Mar-16-2025 | 0.30 $* | 0.47 $* |

| Feb-16-2025 | 0.97 $* | 0.80 $* |

| Jan-16-2025 | 0.91 $* | 0.88 $* |

Характеристики

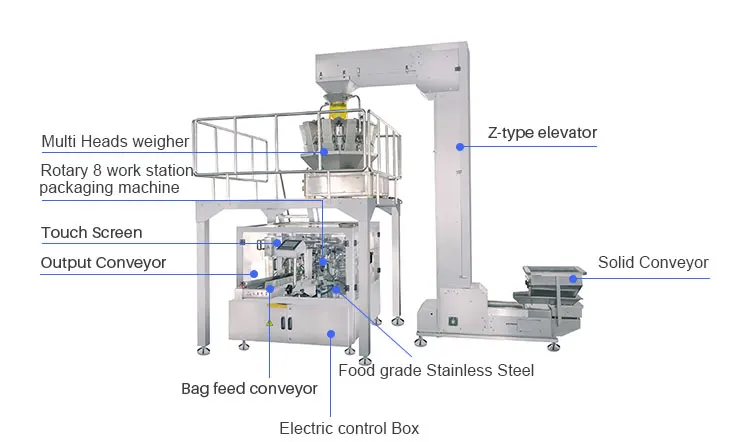

Product Function Introduction

Machine working process

1.Bag Feeding 2.Optional Zipper open and Date print3.Bag mouth and bottom open

4. Product fill 5.Option: Solid :Nitrogen charge,Powder:Bag mouth clean,

Liquid:Secondary filling 6.Heat sealing 7.Heat sealing 8.Output

4. Product fill 5.Option: Solid :Nitrogen charge,Powder:Bag mouth clean,

Liquid:Secondary filling 6.Heat sealing 7.Heat sealing 8.Output

after-sale service | Global after sales service,fast delivery of spare parts. |

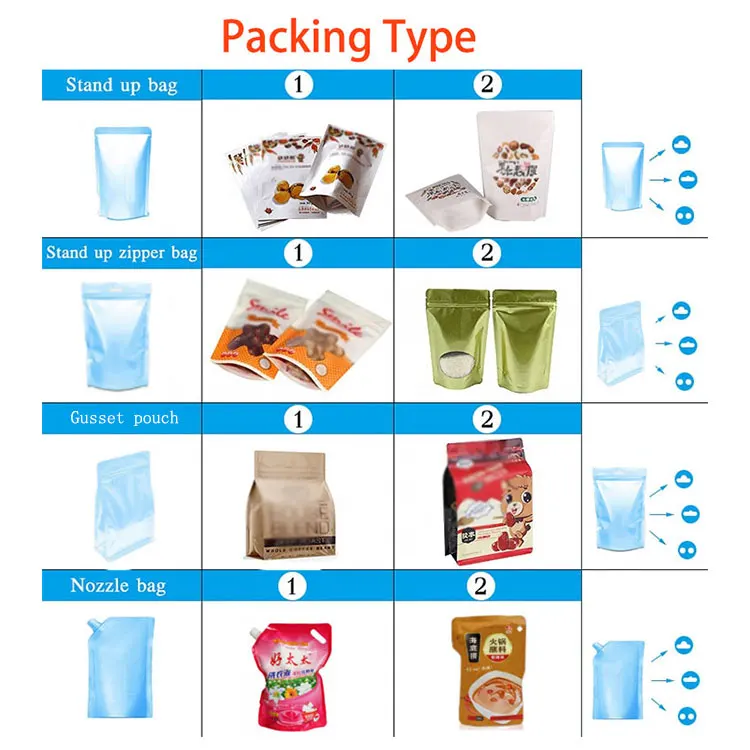

Various bag types | 3 side bag ,4 side bag ,Stand up pouch ,Stand up pouch with hole,Spout pouch ,Gusset pouch ,Shaped bag ,Stand up pouch with zipper etc. |

bag width | 80-305mm |

bag length | 100-380mm |

Capacity | 15-90 bag/min |

custom | Just Tell us : Weight or Bag Size required. |

Fill station | Max 3 |

Parts of Machine | ||||||||

Parts | PLC | Touch Screen | Frequency Conveter | Vacuum Pump | ||||

Brand | SIEMENS | SIEMENS | Danfoss | ORION | ||||

Oringin | Germany | Germany | Holland | Japan | ||||

Parts | Main Motor | Temperature Controllor | Pneumaticelements | AC contactor | ||||

Brand | SEW EURODRIVE | OMRON | SMC | Schneider | ||||

Oringin | Germany | Japan | Japan | France | ||||

Product Display

Detailed Images

Bag zipper open device

Bag mouth and bottom open

Product Filling

Bag mouth clean

Bag Sealing Device

Date print(Option)

multihead weigher(Option)

Conveyor(Option)

Easy control touch screen

Product Advantage

* Easily operated, 10”PLC controlled, and properly integrated with built-in touch screen and electric control system. The HMI is user-friendly.

* Automatic checking: no pouch or pouch open error, no fill, no seal. The bag can be used again, avoid wasting packing materials and raw materials.

* Uses sealed bearings, no oil required.

* Uses a no oil vacuum pump, to avoid polluting the production environment.

* Positive bag opening system with suction and air blast.While the suction cups are pulling open the bottom of the pouch/ bag; the windpipe releases a blast of air to open up the bag fully to the bottom in order to avoid the material overflow from the bag if the it is not opened fully.

* The packing materials loss is low; this machine uses a preformed bag. The bag pattern is perfect and is high quality, the sealing system has consistent pressure and cooling time so the seal integrity is achieved.

* Stainless steel frame, with elegant a ppearance by top grade and stable operation; The product contact parts are adopted sus304 stainless steel to ensure sa nitation and safety, meet the GMP standard.

* Be able to integrate with multi-head weigher, screw feeder & screw conveyer, bottle flling machine, z-shaped Bucket Elevator in automatic line.

* Safety device: Machine stop at abnormal air pressure, heater disconnection alarm.

OPTIONAL: Horizontal conveyor style for bag presentation: loading belt can hold greater amounts of bags than hopper. As the bags are fed to the pickup device a thinner bag structure can be used (if application permits) creating greater yield on your packaging material.

OPTIONAL: The width of the bags can be adjusted by electrical motor. Press the control-button can adjust the width of clips, ease of operation to save time.

* Automatic checking: no pouch or pouch open error, no fill, no seal. The bag can be used again, avoid wasting packing materials and raw materials.

* Uses sealed bearings, no oil required.

* Uses a no oil vacuum pump, to avoid polluting the production environment.

* Positive bag opening system with suction and air blast.While the suction cups are pulling open the bottom of the pouch/ bag; the windpipe releases a blast of air to open up the bag fully to the bottom in order to avoid the material overflow from the bag if the it is not opened fully.

* The packing materials loss is low; this machine uses a preformed bag. The bag pattern is perfect and is high quality, the sealing system has consistent pressure and cooling time so the seal integrity is achieved.

* Stainless steel frame, with elegant a ppearance by top grade and stable operation; The product contact parts are adopted sus304 stainless steel to ensure sa nitation and safety, meet the GMP standard.

* Be able to integrate with multi-head weigher, screw feeder & screw conveyer, bottle flling machine, z-shaped Bucket Elevator in automatic line.

* Safety device: Machine stop at abnormal air pressure, heater disconnection alarm.

OPTIONAL: Horizontal conveyor style for bag presentation: loading belt can hold greater amounts of bags than hopper. As the bags are fed to the pickup device a thinner bag structure can be used (if application permits) creating greater yield on your packaging material.

OPTIONAL: The width of the bags can be adjusted by electrical motor. Press the control-button can adjust the width of clips, ease of operation to save time.

Product Application

Pre-made pouch packing machine have a wild application, it can be used to pack various materials: liquid, sauce, powder, granule, solid, just choose different filling devices according to different materials.Solid type:All kinds of grains and solids material,nuts,chips,fried food,frozen food, pet food etc.

Pre-made pouch packing machine can be equipped with a variety of filling device systems.For example, intelligent combination weighing system, screw weighing system, liquid paste filling system, pickles filling system, measuring cup filling system, and other special product' s filling system.All of them can be easily combined with other external supporting equipment.

* Various bag types are available:3 side bag ,4 side bag ,Stand up pouch ,Stand up pouch with hole,Spout pouch ,Gusset pouch ,Shaped bag ,Stand up pouch with zipper etc.

Customer Real Feedback

Company Profile

FAQ

Q1.Are you a trading company or manufacture?

We are a professional manufacturer with experiences over 23 years. We started this rotary fill and seal machine since 1997.

Q2.Why choose us?

We are a professional manufacturer of packaging machinery.With a strict and effective quality control system, our products are CE approved, and we have ISO9001 Certificate.With numerous in-house service technicians and engineers, we are ready to assist when you need dedicated and knowledgeableexpertise.

Q3.What is your delivery time?

Normally 30-45 working days upon order confirmation and down payment.

Q4.What kind terms of payment can be accepted?

Normally TT. Or L/C if customers order amount is more than 150K USD.Q5.What about the warranty time?

1).Our packing machine is 12 months under warranty. Artificial and thunder strike damage is out of the scope of the warranty.Spare parts are not in the warranty time.

We are a professional manufacturer with experiences over 23 years. We started this rotary fill and seal machine since 1997.

Q2.Why choose us?

We are a professional manufacturer of packaging machinery.With a strict and effective quality control system, our products are CE approved, and we have ISO9001 Certificate.With numerous in-house service technicians and engineers, we are ready to assist when you need dedicated and knowledgeableexpertise.

Q3.What is your delivery time?

Normally 30-45 working days upon order confirmation and down payment.

Q4.What kind terms of payment can be accepted?

Normally TT. Or L/C if customers order amount is more than 150K USD.Q5.What about the warranty time?

1).Our packing machine is 12 months under warranty. Artificial and thunder strike damage is out of the scope of the warranty.Spare parts are not in the warranty time.

2).Maintenance after warranty period

Any machine problems after warranty period, we will provide you same quality spare parts and maintenance service with the best favorable price.

Q6. How about your service?

We have service all over the word. We could send engineers from China who is English speaking or help the customer with our distributors from his country. We can provide the customer with the user training for better operation and maintenance of the machine.

Q7. What information should we need?

1)products details, e.g.solid products specific sizes, weights of each piece, powder density.

2)Bag sizes and types with pictures or samples

3)Packing weight

4)Packing speed, accuracy required

5)Special requirements, such as second fill, Nitrogen flash, zipper close, date printing

6)Power supply voltage, Frequency etc

7)Factory workshop space, Height etc.

Any machine problems after warranty period, we will provide you same quality spare parts and maintenance service with the best favorable price.

Q6. How about your service?

We have service all over the word. We could send engineers from China who is English speaking or help the customer with our distributors from his country. We can provide the customer with the user training for better operation and maintenance of the machine.

Q7. What information should we need?

1)products details, e.g.solid products specific sizes, weights of each piece, powder density.

2)Bag sizes and types with pictures or samples

3)Packing weight

4)Packing speed, accuracy required

5)Special requirements, such as second fill, Nitrogen flash, zipper close, date printing

6)Power supply voltage, Frequency etc

7)Factory workshop space, Height etc.

Похожие товары

Автоматическая машина для упаковки зерна JKPACK

US $6000-$6800

Новая высококачественная упаковочная машина для мешков в саше, на молнии

US $20000-$500000

Автоматическая упаковочная машина для муки с открытым горлом

US $2000-$4000