Установка для непрерывного литья вверх медный стержень без содержания

- Категория: Машины для литья металла >>>

- Поставщик: Wuxi,Jintong,Furnace,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.80 $* | 0.73 $* |

| Aug-19-2025 | 0.70 $* | 0.0 $* |

| Jul-19-2025 | 0.82 $* | 0.15 $* |

| Jun-19-2025 | 0.58 $* | 0.59 $* |

| May-19-2025 | 0.76 $* | 0.50 $* |

| Apr-19-2025 | 0.57 $* | 0.87 $* |

| Mar-19-2025 | 0.7 $* | 0.45 $* |

| Feb-19-2025 | 0.61 $* | 0.80 $* |

| Jan-19-2025 | 0.64 $* | 0.65 $* |

Характеристики

Product Application

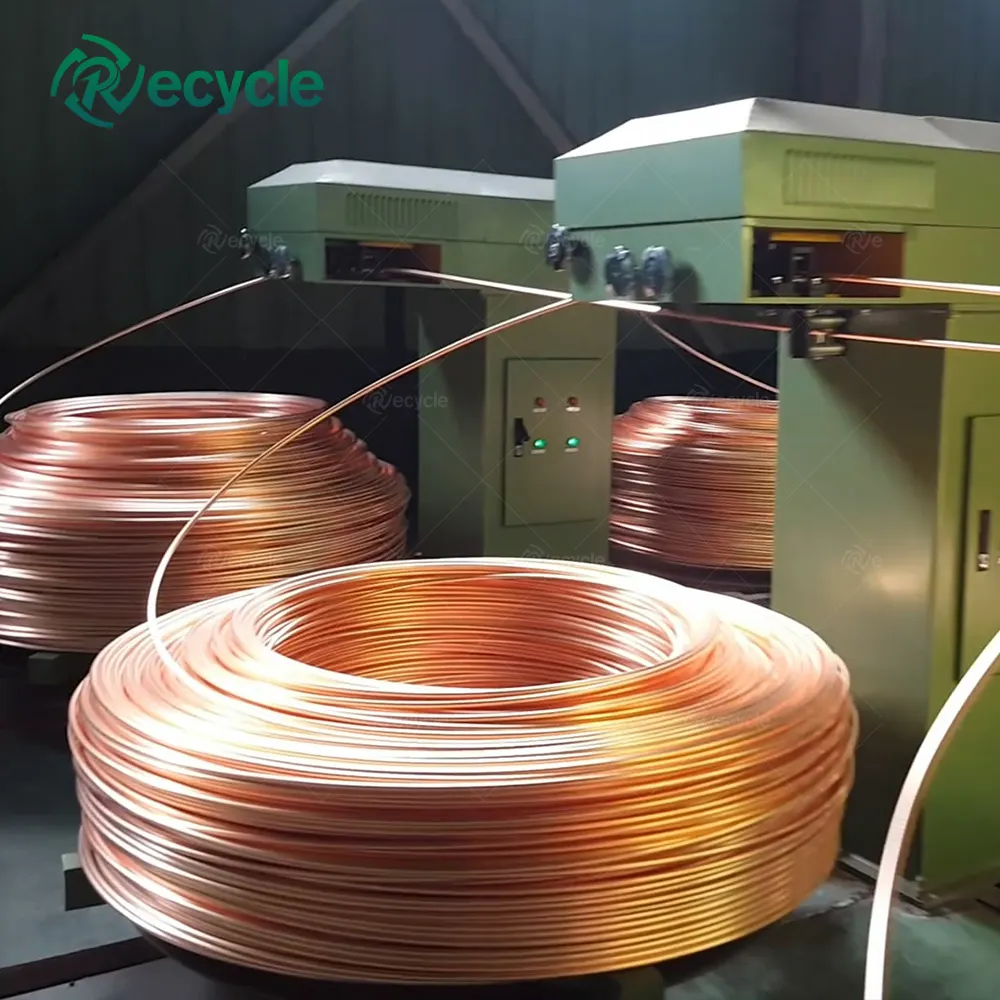

- Copper rod continuous casting machine is specially used for making copper rod with different sizes. The production procedures are as follows:

- copper cathode to be put in the furnace through the lifting system for baking

- adjust the feeding speed according to the casting speed

- feed the copper cathode into the melting furnace for melting (charcoal or graphite scale to be used for avoiding the oxygen)

- copper liquid flow into the transition part (charcoal or graphite scale still need to be used for avoiding the oxygen)

- copper liquid flow into the holding furnace (charcoal or graphite scale still need to be used for avoiding the oxygen)

- copper liquid flow into the crystallizer, and the copper rods come out from crystallizer

- copper rods flow into the upward casting device and go through the output frame

- copper rods go through the separate shelf on the top (to separate each rod)

- copper rods go through the support rack on the ground (to control the take up speed)

- copper rods go through the take up machine, and finish coiling.

Copper Melting and Holding Furnace

No. | Parameters: |

1 | Rated Power: 240Kw (melting furnace 160kw, holding furnace 80kw) |

2 | Type: Melting Copper Scrap/Temperature Holding |

3 | Model: GYT300/300/300 |

4 | Input voltage: 380 VAC |

5 | Content Capacity: 6000KG |

6 | Input phase: 3 phase (ABC) |

7 | Power Factor: 0.95 |

8 | Input Frequency: 50 Hz |

9 | Melting Rate: 600KG/Hour |

10 | Working Temperature: 1200 ℃ |

11 | Hook: 3 |

12 | Cooling System: Water cooling |

13 | Voltage Regulating: Autotransformer |

14 | Temperature Measurement: Thermocouple |

15 | Electric Cabinet: 3 Sets |

Up-drawing Machine/Traction Machine

No. | Parameters: |

1 | Motor: Servo Motor 3KW (Single Servo Motor) |

2 | Up Drawing Speed: 1800mm/minute |

3 | Copper Rod Diameter: 8mm-17mm |

4 | Copper Rod Qty: 6pcs |

5 | Control: PC Controlled |

Wire Take-up Machine

No. | Parameters: |

1 | Motor: Variable Frequency Motor 3Kw(two sides) |

2 | Speed Reducer: Gear Reducer |

3 | Take-up Reel Capacity: >2000KG/PC |

Wuxi Jintong Furnace Co., Ltd. called Wuxi Xinlian Furnace Factory before was established since year 2004, having 10+ years experience in metal melting and metal heat treatment area. Jintong Manufacturing Corp. is specialized in manufacturing induction melting furnace(copper scrap brass scrap, aluminium scrap, zinc scrap, bronze scrap, steel, iron, stainless steel, carbon steel scrap and precious metal like gold or silver). Our furnaces can be applied to many fields such as copper/brass rod/pipe continuous casting, zinc ingot, aluminum rod continuous casting or power resistance.

We sincerely invite you to visit our factory and offer your valuable guidance. Looking forward to cooperating with you.

Our Customers:

FAQ

Q. What is your MOQ?

A. 1 set.

Q. Your company is a trading firm? or Factory?

A. We are a factory with 10+ years experience in industrial melting feild. We currently have three branches: main frequency furnace production, medium frequency furnace production, component machine production. You are warmly welcomed to visit our factories.

Q. How is your products quality?

A. As a manufacturer, we have our own R&D team. Basing on several years of technical innovation, we have accumulated successful experience in induction heating, temperature holding, fast melting. We've customized so many furnaces with all positive feedbacks.

Q. What kind of material our furnace can melting?

A. Jintong is able to supply a melting production line such as copper/zinc/aluminum melting line.Jintong medium frequency furnace can also melt iron, steel, gold, silver and so on.

Q. I am not so familiar with your machine now. I am not sure I can use it well if I buy it from you.

A. Don't worry about this. With the machine, we will send you a brochure with detailed information of our machine operation. In addition, we will send you videos of machine set up and using. Our engineers are always available for consultation. Engineers can support at your place if it is needed.

How to Contact

How to Contact Us?

Please provide us with following basic information:

What product you want to make?

What kind of raw material do you have? (Pictures are very appreciated)

What capacity do you need, daily, monthly or yearly?

What is the working hours there every day?

Whatsapp/Wechat: 0086 15906188353

Send your Inquiry Details Below , Click "Send" Now !