Сжималка и гранулятор для пластиковой полиэтиленовой полипропиленовой

- Категория: Plastic Drying Machines >>>

- Поставщик: Zhangjiagang,Lonham,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 1768985.89 $* | 1857434.78 $* |

| Aug-18-2025 | 1754120.96 $* | 1841826.25 $* |

| Jul-18-2025 | 1471677.14 $* | 1545261.14 $* |

| Jun-18-2025 | 1724389.25 $* | 1810608.40 $* |

| May-18-2025 | 1501407.79 $* | 1576477.57 $* |

| Apr-18-2025 | 1694658.80 $* | 1779391.48 $* |

| Mar-18-2025 | 1679792.69 $* | 1763782.7 $* |

| Feb-18-2025 | 1664927.43 $* | 1748173.25 $* |

| Jan-18-2025 | 1650062.4 $* | 1732565.92 $* |

Характеристики

Product Application

1) This machine is our new designed machine, made by the advanced Japan techniques, specially screw pressing dewatering design;

2) Equipped with Speed reducer, hard gear box.

3) It is equipped with a electric control cabinet, feeder mouth is easy to control the drying effect;

4) This machine is especially for plastic film, plastic bags, woven bags, Jumbo bags. Solve the drying problem in the past.

5) Instead of the dewatering machine, hot blower in the recycling line.

6) Easy to operate, drying effect can reach to 98%, the final product moisture is around 1%~2%.

Main Technical Specification

Model | Screw Diameter (mm) | Main Motor Power (kw) | Capacity (kg/hr) |

LHSD300 | 300 | 90 | 500-700 |

LHSD350 | 350 | 132 | 700-900 |

LHSD400 | 400 | 160 | 900-1000 |

semi-finished product

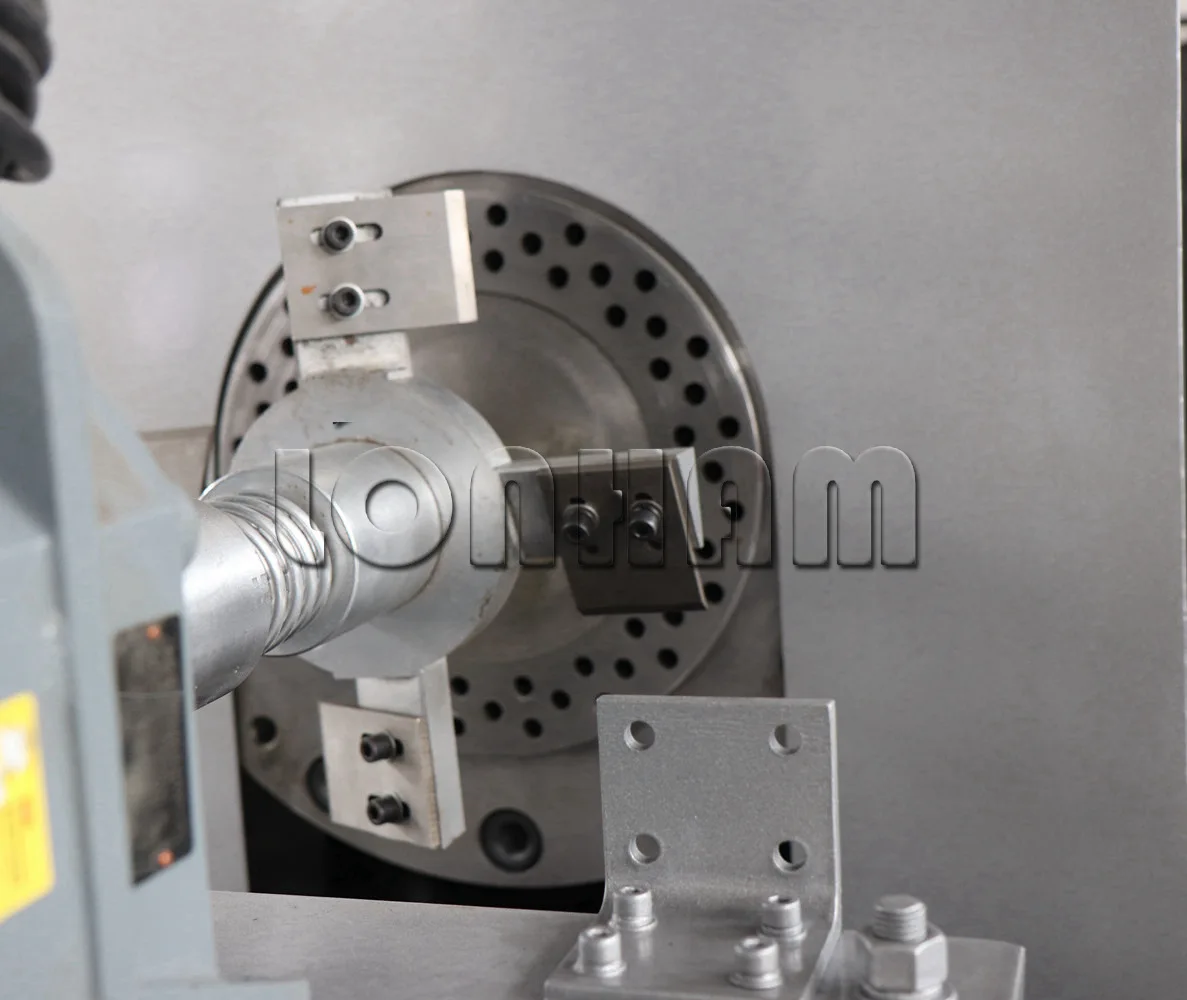

Special designed Screen

Cutter

Delta PLC Touch Screen

Model B: Squeezing heating without cutting

Model C: Squeezing heating and cutting

Equipment selection, technical negotiation process:

1. Let you know machines' details technical specification and character.

2. Designing the machines and arrange the water, electric layout according to your requirement.

3. We can provide turnkey project according to your requirement.

Equipment production process:

1. Improve product quality through advanced production management.

2. Let you know production schedule through regular pictures, video, show the real production process to you.

3. Invite you or your third party, to our factory to test, inspection machine before shipment, until you are satisfied.

Equipment operation process:

1. Engineers are available to your factory for installation, commissioning, technical guidance and personnel training.

2. The equipment is completely free of charge for 12 months warranty. Spare parts are supplied with cost prices after 12moths after warranty time.

3. Establish the customer database, all the sold equipment can be checked any time.

4. Visit customers regularly, follow up the usage of each customer's equipment.

5. Increase service stations gradually, effectively improve service and spare parts supply speed.

Похожие товары

Пластиковые гранулы PE сушилка для машины для литья под давлением

Европейская пластиковая стандартная сушилка с бункером

Воздушная сушилка Zillion с тепловым резервуаром, пластиковая сушилка 50 кг

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com