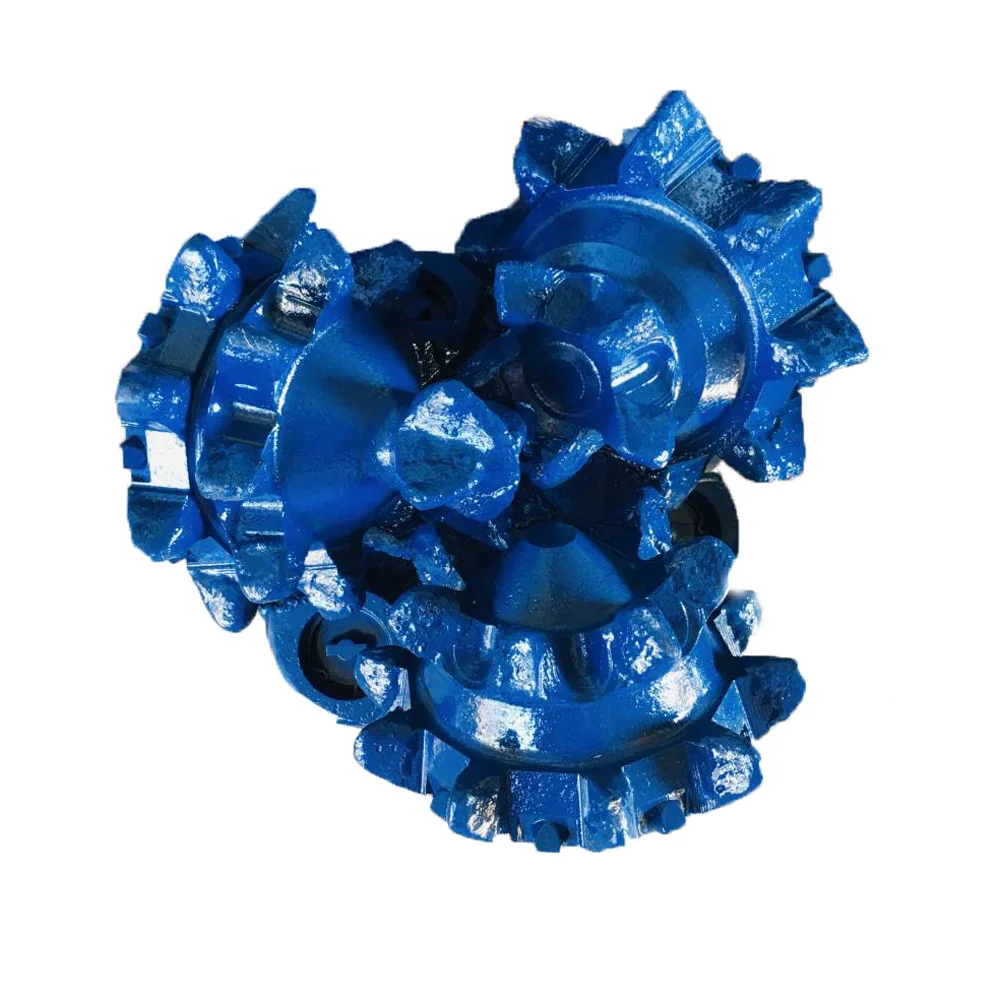

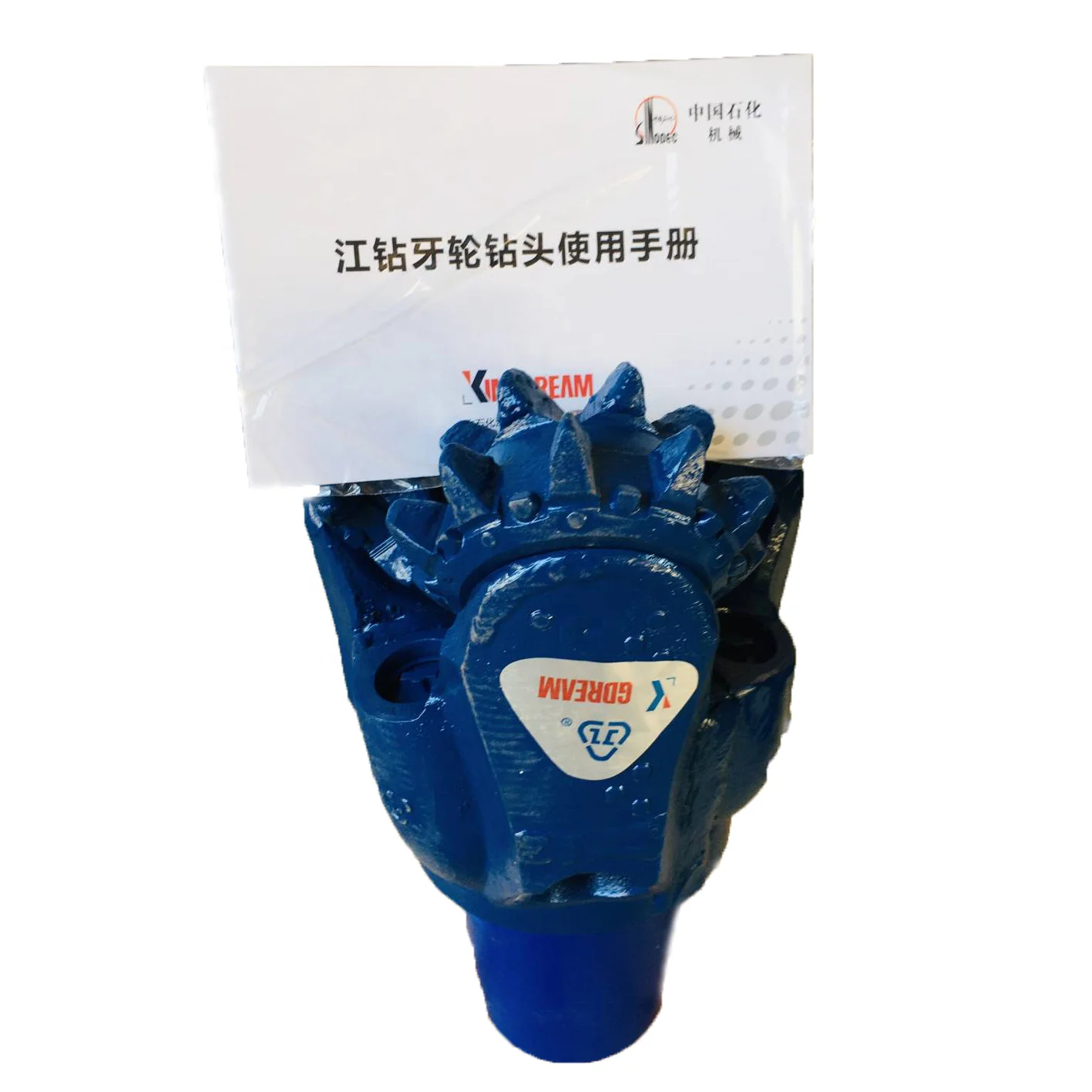

Трехшарошечное долото для бурения скважин с твердым образованием API 8 1/2 дюйма HAT127

- Категория: Mining Machinery Parts >>>

- Поставщик: Hejian,Deris,Petroleum,Drilling,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 2209.46 $* | 2253.30 $* |

| Jul-19-2025 | 1791.75 $* | 1827.70 $* |

| Jun-19-2025 | 2174.53 $* | 2217.61 $* |

| May-19-2025 | 2156.3 $* | 2199.28 $* |

| Apr-19-2025 | 1722.50 $* | 1756.31 $* |

| Mar-19-2025 | 2122.65 $* | 2164.48 $* |

| Feb-19-2025 | 2104.18 $* | 2146.48 $* |

| Jan-19-2025 | 2087.78 $* | 2129.42 $* |

Характеристики

Product Description

HAT bit rubber seal with journal bearing

HAT series bit adopts rubber seal with journal bearing,which can sustain higher WOB under normal rotary speed and is suitable for drilling in formations from very soft to middle hard by properly selecting different cutting structure.

Main structure features

1.Journal bearing. Hardfaced head bearing surface. Inner hole of cone is silver-plated. The load capacity and seizure resistance of the bearing is greatly improved. O ring seal is made of the more wear resistance high saturated buna-N with the increased seal section and precisely designed sealing flange in the cone sealing area increased the reliability of the seal.

2.All rubber compensator is used which can limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication.

HAT series bit adopts rubber seal with journal bearing,which can sustain higher WOB under normal rotary speed and is suitable for drilling in formations from very soft to middle hard by properly selecting different cutting structure.

Main structure features

1.Journal bearing. Hardfaced head bearing surface. Inner hole of cone is silver-plated. The load capacity and seizure resistance of the bearing is greatly improved. O ring seal is made of the more wear resistance high saturated buna-N with the increased seal section and precisely designed sealing flange in the cone sealing area increased the reliability of the seal.

2.All rubber compensator is used which can limit pressure differential and prevent drilling fluid from entering the lubrication system and this provides the bearing system with good assurance of lubrication.

3. For steel tooth bit the tooth surface is hardface with new type of wear resistant material and thus extended working life of the cutting structure while still maintaining high ROP.

Basical Specification | ||

Size of tricone bit | 8 1/2" 215.9mm | |

Connection | 4 1/2" Reg Pin | |

IADC CODE | HAT 127 | |

Bearing type | Sealed journal bearing | |

Operating Parameters | ||

Recommended Make up torque | 16.3~21.7 KN.M | |

WOB (Weight On Bit) | 0.35~1.00KN/mm | |

Rotary speed | 180~80 r/min | |

Formation | soft with Low compressive strength and high drillability. Such as shale, clay, salt bed and soft limestone etc | |

Drill bit application instructions

1 bit selection

1. Please reading lithology description and bit records of adjacent wells carefully,and analyzing formation characteristics.

2. Selecting appropriate type in accordance with lithology.

2 Preparation before drilling

1.Inspect previous bit for body damage, lost cutters or inserts etc. Make sure there are no any junk on bottom hole, and clean the bottom hole if necessary.

2.Bit must be handled with care in order not no damage cutters and hard substances.

3.Check if there is any damage on bit cutters and if there any foreign matter inside the bit.

4.Check if installing nozzle is meet requirements, and replace nozzles if necessary.

1. Please reading lithology description and bit records of adjacent wells carefully,and analyzing formation characteristics.

2. Selecting appropriate type in accordance with lithology.

2 Preparation before drilling

1.Inspect previous bit for body damage, lost cutters or inserts etc. Make sure there are no any junk on bottom hole, and clean the bottom hole if necessary.

2.Bit must be handled with care in order not no damage cutters and hard substances.

3.Check if there is any damage on bit cutters and if there any foreign matter inside the bit.

4.Check if installing nozzle is meet requirements, and replace nozzles if necessary.

3 Marking up the bit

1.Clean bit threads and apply grease on threads.

2.Fit the breaker to the bit, lower the drill string onto the pin and engage the threads.

3.Locate the bit and breaker in the rotary bushing, and make-up the bit to be recommended torque.

4 Tripping in

1.Remove the breaker and carefully lower the bit through the wellhead device in order not to damage it.

2.Shrinkage,shoulder,dogleg and key seat of borehole should be cautious when bit through blank hole.

3.Start pump and cycle drilling fluid to wash buttom hole when drill to a point about 30 meters to bottom of the hole, and rotate drill string at the low speed not more than 60rpm.

4.Approach the bottom approximately half meter. Circulate for 5 to 10 minutes with full flow.

2.Fit the breaker to the bit, lower the drill string onto the pin and engage the threads.

3.Locate the bit and breaker in the rotary bushing, and make-up the bit to be recommended torque.

4 Tripping in

1.Remove the breaker and carefully lower the bit through the wellhead device in order not to damage it.

2.Shrinkage,shoulder,dogleg and key seat of borehole should be cautious when bit through blank hole.

3.Start pump and cycle drilling fluid to wash buttom hole when drill to a point about 30 meters to bottom of the hole, and rotate drill string at the low speed not more than 60rpm.

4.Approach the bottom approximately half meter. Circulate for 5 to 10 minutes with full flow.

Title goes here.

5 Reaming

1.Reaming long sections of under gauge hole is not recommended.

2.If reaming operation is necessary, it is strongly recommended that the reaming operation should be done with maximum flow rate circulation,specific weight on bit not exceed 90N/mm (diameter),rotary speed not exceed 60 rpm where stuck was encountered when tripping in.

1.Reaming long sections of under gauge hole is not recommended.

2.If reaming operation is necessary, it is strongly recommended that the reaming operation should be done with maximum flow rate circulation,specific weight on bit not exceed 90N/mm (diameter),rotary speed not exceed 60 rpm where stuck was encountered when tripping in.

6 Bit break-in

1.Overusing display instruments when bit approach bottom hole. If the WOB and torque increase,that shows bit have arrived at bottom hole.Use not more than 90N/mm,weight on bit and 40 to 60 rpm to establish the bottom hole pattern at least half meter.

2.Bit break-in is finished and should be adjusted RPM to obtain optimal drilling parameter combination.

3.Drilling parameters adjustment should be selected within the limits of the recommended parameters refer to recommended drilling parameters optimization method.

2.Bit break-in is finished and should be adjusted RPM to obtain optimal drilling parameter combination.

3.Drilling parameters adjustment should be selected within the limits of the recommended parameters refer to recommended drilling parameters optimization method.

7 Normal drilling

1.Drilling situations should be monitored and analyzed during, so that we can judge complex condition and take corresponding measures.

2.See the table of complex circumstance in this manual for any conditions and treatment action.

1.Drilling situations should be monitored and analyzed during, so that we can judge complex condition and take corresponding measures.

2.See the table of complex circumstance in this manual for any conditions and treatment action.

Detailed Images

A row of inserts is added between gauge row and heel row of HA bit to trim borehole wall and protect cone shell and

consequently,the special HAT series bit is formed.

consequently,the special HAT series bit is formed.

Related Products

Packing&Shipping

Package Type : wooden case ,also be packaged according to customers requirement

Transportation : by sea , by air or land transportation . Less than 50kg shipping by courier better

Delivery : If we have stock, the delivery time will need about 2~3 working days. In general, common size tricone bits and pdc bit, we have stock.

If we have no stock, such as the tci reamer and pdc hole opener, it will be 7-10 working days in total.

Transportation : by sea , by air or land transportation . Less than 50kg shipping by courier better

Delivery : If we have stock, the delivery time will need about 2~3 working days. In general, common size tricone bits and pdc bit, we have stock.

If we have no stock, such as the tci reamer and pdc hole opener, it will be 7-10 working days in total.

Company Introduction

Hejian Deris Petroleum Drilling Equipment Co., Ltd established in 2000 ,is a professional manufacturer and supplier of drilling Located in the Junziguan industrial park,Hejian city ,Hebei province ,China Near Beijing airport and Tianjin seaport Experience: 12 years production experience

Tools-Tricone bit, PDC bit, Hole opener, drag bit ,hammer bit, core bit and tools ,tricone bit cutters drilling pipe etc .

Our principle -Doing a professional job that meets our customers needs

Quality policy-Perfect teamwork to provide high quality products to our valuable customers as per their requirements on time

Objectives-Usage of best raw material and on time delivery . Quality checking at every stage. Immediate action upon customer complaints Adopt of up date for the enhancement of performance

Tools-Tricone bit, PDC bit, Hole opener, drag bit ,hammer bit, core bit and tools ,tricone bit cutters drilling pipe etc .

Our principle -Doing a professional job that meets our customers needs

Quality policy-Perfect teamwork to provide high quality products to our valuable customers as per their requirements on time

Objectives-Usage of best raw material and on time delivery . Quality checking at every stage. Immediate action upon customer complaints Adopt of up date for the enhancement of performance

FAQ

1. About lead time?

Answer: Answer: We always have regular model stock, i.e. payment on delivery, which is our advantage. Batch production depends on the number of orders. It usually takes three to five days to get to Tianjin Port or Beijing Airport in China. Even small or urgent orders can be shipped to you by air or express upon receipt of your consent. According to the distance from China to your port, it takes about 30 days to ship from China to Europe. It takes about 25 days to ship to the west of the United States.

2. About payment terms?

Answer : We accept all regular payment terms, including letters of credit, T/T, etc. 100% payment through Alibaba Trade. Please pay 30% T / T in advance for customization.

3. How to get an exact quotation?

Answer: Drilling depth in vertical drilling, drilling length in hard disk, hardness of rock, and capacity of drilling rig. FOB or

CIF or CFR, by plane or ship, destination port / unloading. An easy way to do this is to send us a photo, the more information you provide, the more accurate the quote.

4. About Transport?

Answer:We are very close to Beijing Airport and Tianjin (Xingang). The transportation from our factory to Beijing or Tianjin takes only one day. It is a fast and very economical inland toll.

5. What is packaging and delivery?

Answer: We use high quality export wooden boxes or you can customize.

6. Can we provide sample service?

Answer :We can provide sample service. 3 7/8 inch, 4 5/8 inch, 5 7/8 inch and 6 inch can offer you free trial service.

7..How do you guarantee your quality?

Answer: All of our production are in lines of API rules and ISO9001 strictly, from signing contract , to raw materials, to

each production processes, to product finish, to after-sale service, each processes and sections are in accordant with standard.

Answer: Answer: We always have regular model stock, i.e. payment on delivery, which is our advantage. Batch production depends on the number of orders. It usually takes three to five days to get to Tianjin Port or Beijing Airport in China. Even small or urgent orders can be shipped to you by air or express upon receipt of your consent. According to the distance from China to your port, it takes about 30 days to ship from China to Europe. It takes about 25 days to ship to the west of the United States.

2. About payment terms?

Answer : We accept all regular payment terms, including letters of credit, T/T, etc. 100% payment through Alibaba Trade. Please pay 30% T / T in advance for customization.

3. How to get an exact quotation?

Answer: Drilling depth in vertical drilling, drilling length in hard disk, hardness of rock, and capacity of drilling rig. FOB or

CIF or CFR, by plane or ship, destination port / unloading. An easy way to do this is to send us a photo, the more information you provide, the more accurate the quote.

4. About Transport?

Answer:We are very close to Beijing Airport and Tianjin (Xingang). The transportation from our factory to Beijing or Tianjin takes only one day. It is a fast and very economical inland toll.

5. What is packaging and delivery?

Answer: We use high quality export wooden boxes or you can customize.

6. Can we provide sample service?

Answer :We can provide sample service. 3 7/8 inch, 4 5/8 inch, 5 7/8 inch and 6 inch can offer you free trial service.

7..How do you guarantee your quality?

Answer: All of our production are in lines of API rules and ISO9001 strictly, from signing contract , to raw materials, to

each production processes, to product finish, to after-sale service, each processes and sections are in accordant with standard.

Похожие товары

Буровое долото из карбида вольфрама 8 1/2 "IADC 537 637 tci tricone

US $200.00-$520.00

Буровая установка поворотного типа

US $100.00-$200.00