2022 новая дизайнерская лабораторная машина для кардинга текстиля

- Категория: Кардочесальные машины >>>

- Поставщик: Hefei,Fanyuan,Instrument,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 15470.74 $* | 16244.91 $* |

| Aug-15-2025 | 15340.6 $* | 16107.52 $* |

| Jul-15-2025 | 12870.99 $* | 13514.84 $* |

| Jun-15-2025 | 15080.99 $* | 15834.68 $* |

| May-15-2025 | 13130.56 $* | 13787.37 $* |

| Apr-15-2025 | 14820.95 $* | 15561.38 $* |

| Mar-15-2025 | 14690.53 $* | 15425.61 $* |

| Feb-15-2025 | 14560.93 $* | 15288.62 $* |

| Jan-15-2025 | 14430.36 $* | 15152.78 $* |

Характеристики

DW7010H Laboratory Textile Carding Machine

Application of textile carding machine:

Laboratory Textile Carding Machine of Spinning is used to comb loose fibers cleaned and opened through the previous opener to produce sliver in cotton spinning mill. The small carding machine is used for processing cotton fiber and chemical fiber, belonging to textile machinery. According to the spinning process, carding is an important process. The former process of the carding machine is to open the cleaning cotton combination machine, and the latter process is the drawing machine (general combing process flow) or the strip winding machine (combing process flow).

Lab Carding machine is to use cover plate type or roller type carding machine, with the aid of needle surface movement, to comb the small cotton bundle into a single fiber state, further remove impurities and non-spinnable short fiber, so that the fiber parallel straight, finally made into a cotton strip disc into a cylinder

What material to use:

Cotton silver wool Silver

FEATURES of textile carding machine:

lDelta brand PLC + touch screen control, easy to learn and operate;

lHigh mechanical-electrical integration degree, stable and reliable;

lUse touch screen as man-machine interface, input technical parameters and show machine running state by touch screen;

lUse standard can coiler to output cotton sliver;

lIntegrated electrical control, easy to maintain;

lIt consists of feeding box, machine, and coiler, of which feeding box makes the feeding evenness;

KEY SPECIFICATIONS of textile carding machine:

l Control mode | Touch screen & PLC |

l Applicable fiber length | 22~50mm |

l Working width | 480mm |

l Feed quantity | 4~6kg/h |

l Feed roller diameter | Φ250mm |

l Feed roller speed | 750rpm |

l Cylinder diameter | Φ446mm |

l Cylinder speed | 750rpm |

l Cover plate qty (Working/Total) | 20/41 |

l Doffer diameter | Φ258mm |

l Doffer speed | 13rpm |

l Can diameter | Φ250mm |

l Large touch screen.

l It is easy to operate for customer . and more suit for University teaching and Lab research

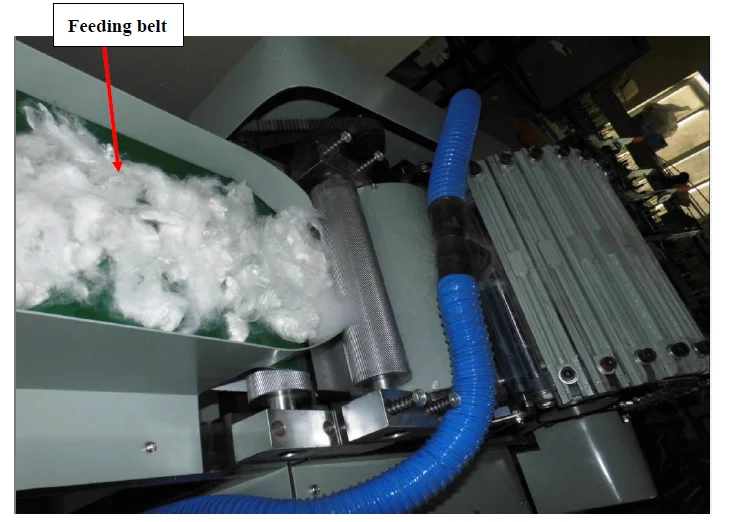

l With Feeding belt thus can feeding material quickly

l Can be used for wool fiber or chemical fibers.

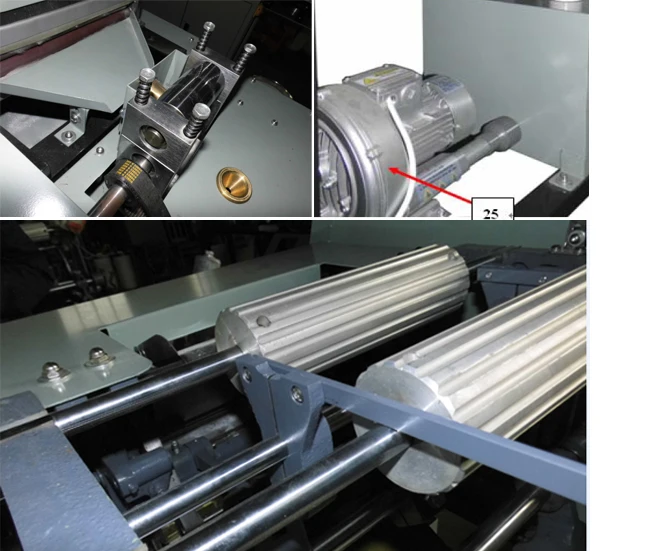

l Equipped with imported Motor ,high efficiency and easy to control

l Stainless appearance , Mini sample lab carding machine .and suit for Lab researching . Save the cost and save the space

· Large Roller and easy to clean .

· It equipped with hopper to improve the quality of output sliver of course can produce web or sliver according to customer optional .

Installation in customer's lab Training in FYI showroom

Customer in our factory

Standard wooden packaging

Environment required to install the machine must meet requirements as below:

· Dry place, no drips, steam or oily dust;

· No corrosive, flammable gas or liquid;

· Solid base and no vibration;

· No electromagnetism and noise;

· To minimize electrostatic charge, it is much better if constant temperature &

· humidity room, 28℃;

Electrical wiring must follow regulations as below:

· In order to ensure safety, once the wiring specifications is selected, please follow the electrical wiring regulations to implement;

· The machine must be separately grounded. It is best not to ground with other equipment. (We recommend using two metal rods about 2 meters that 2.5meters far away hit into the ground, who’s upper connected with a wire and then connected to the ground terminal of the machine.