Высококачественная режущая и Резьбовая прокатная линия для резки арматуры с

- Категория: Проволочноволочильные станки >>>

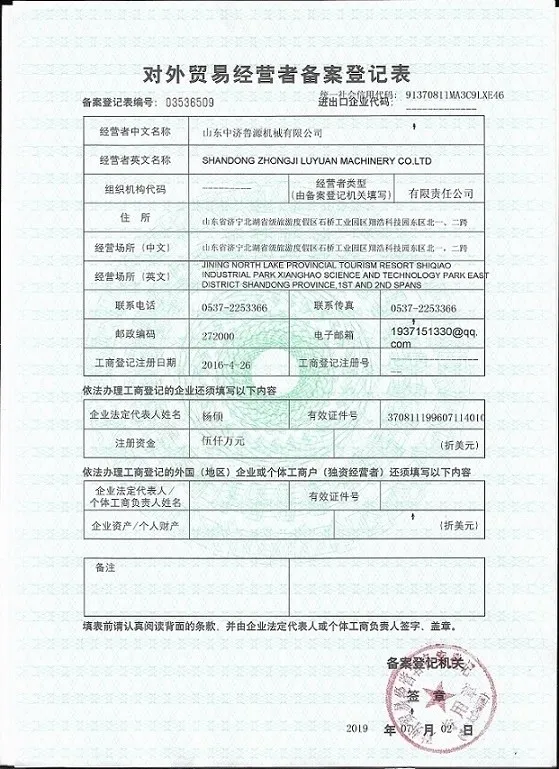

- Поставщик: Shandong,Zhongji,Luyuan,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 58310.29 $* | 61226.45 $* |

| Aug-17-2025 | 57820.4 $* | 60711.34 $* |

| Jul-17-2025 | 48510.15 $* | 50936.59 $* |

| Jun-17-2025 | 56840.36 $* | 59682.59 $* |

| May-17-2025 | 49490.24 $* | 51965.76 $* |

| Apr-17-2025 | 55860.4 $* | 58653.34 $* |

| Mar-17-2025 | 55370.28 $* | 58139.50 $* |

| Feb-17-2025 | 54880.59 $* | 57624.62 $* |

| Jan-17-2025 | 54390.86 $* | 57110.85 $* |

Характеристики

Product Description

Top Quality CNC Rebar Saw Cutting and Thread Rolling Line

The automatic production of steel bar saw cutting, thick pier, thread and grinding process is realized, which improves the automation degree of thread production equipment and reduces labor force.

Feature:

*Labor saving:high degree of automation, greatly reduce the labor.

* Feeding convenient:the machine is equipped with transverse feeding device, which is convenient for feeding.

* Space saving :after the steel bar is cut to the specified length , it goes directly into the thread equipment

* Time saving:in the shortest time to achieve from raw materials to both ends of the semi-finished wire

Specification:

Details Images

Sawing machine parts

The sawing machine adopts China famous brand Chen-long sawing machine, hydraulic controlled sawing feed, non-pole adjustable workpiece tightening, double vise tightening, so that the sawing is more stable, the band saw blade adopts rolling bearing, and hard alloy guide, extend the service life of the saw blade.

Cutting parts

The drive wheel adopts groove design to increase friction and prevent slipping while transferring steel.

Cutting parts

It adopts automatic manual combination, automatic feeding trolley, automatic sizing, servo motor control for the whole positioning of 12 meters, accuracy ±2mm.

Set of wire transmission

The distance between V-shaped wheels is 50cm and the distance is small, so there will be no transmission failure when transferring short reinforcing bars.

Sleeve conveyor wheel

Precision casting V groove wheel, special material heat treatment process, high hardness, wear resistance, more accurate and durable transmission.

Transducer

Schneider sensor is adopted, which has large and sensitive sensing area.

Set of wire part

Set of wire machine set of wire diameter Φ 45 biggest, adopts 7.5 kw power motor, wire faster.

Set of grind part

Sandpaper grinding method is adopted.The finished workpiece has no burr and is more smooth when connecting the sleeve.

Transimission

Adopt belt type soft connection, protect motor, reducer, chain, failure rate greatly reduced, maintenance cost greatly reduce (only need to replace belt).

Finished Goods

Elegant appearance

Our Company

Our Service

Pre-sale Service

1. According to your requirements to help you design a reasonable solution,choose a reasonable equipment .

1. According to your requirements to help you design a reasonable solution,choose a reasonable equipment .

2.In-depth explanation of customer service scheme by design experts.

Sale Service

1. Provide the video to help you to learn about how the device works.

2.Help you to know the details of the Key parts and our advantage.

After-sales Service

1. Guarantee for One year.

2. Quality problem, we will send you the accessories.

3. Free repair whole using life (without the freight and accessories charge)

4.24 hours maintenance response: timely feedback within 24 hours after acceptance of maintenance service.

5. Customer can enjoy lifelong value maintenance.

6. Professional and international experienced after-sales service team.

Sale Service

1. Provide the video to help you to learn about how the device works.

2.Help you to know the details of the Key parts and our advantage.

After-sales Service

1. Guarantee for One year.

2. Quality problem, we will send you the accessories.

3. Free repair whole using life (without the freight and accessories charge)

4.24 hours maintenance response: timely feedback within 24 hours after acceptance of maintenance service.

5. Customer can enjoy lifelong value maintenance.

6. Professional and international experienced after-sales service team.

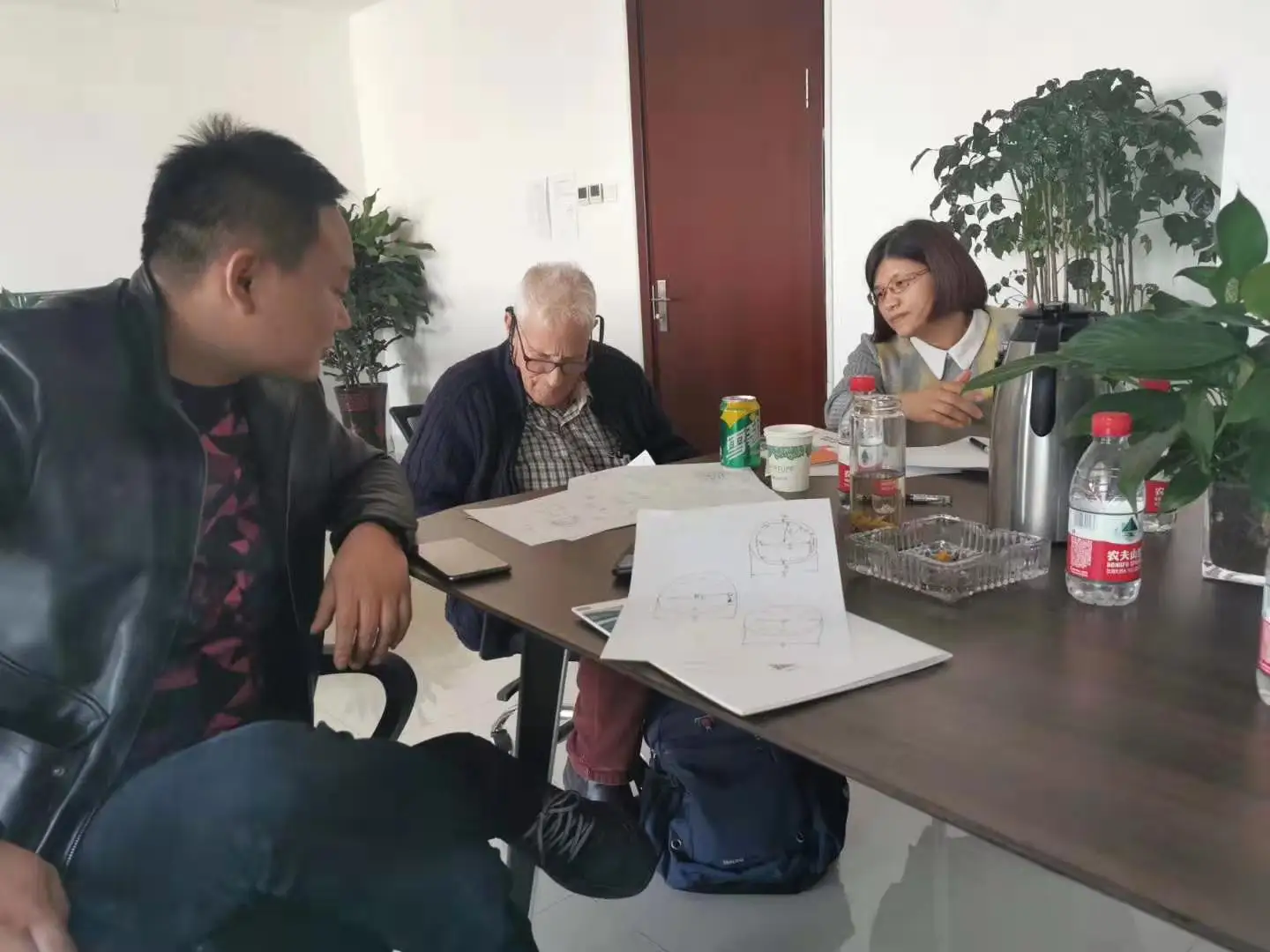

Customer Photos

Certifications

Recommend Products

FAQ

1. Q: Are you a factory or trading company?

A: We are a professional manufacturer with strong capability in research, development and manufacturing, you can not only get the factory price but also can enjoy the "ultra-high quality and professional design" unique to Zhongjiluyuan.

2. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Jining City, Shandong Province, China. You can visit us by air to Qufu airport, or by the high-speed rail. All the customers, from home or abroad, are warmly welcome to visit us!

3. Q: Can you do OEM?

A: Yes, we can do OEM as client's requirement.

4.Q: All products have a warranty?

A:YES, Our warranty term is One Year.

5.Q:What about the delivery time?

A:Usually3-10 days after down payment, the exact delivery time is according to the production season and order quantity.

6. Q: What is the biggest advantage of the company?

A: Stable Better Quality and Perfect Service .

Our company is a state high-tech enterprise, our rebar processing machinery are used in hundreds of infrastructure projects both with China and abroad. We have the most complete after-sales service support system ,"8-level quality assurance system," truly lifelong maintenance,customer satisfaction is almost 100%.

A: We are a professional manufacturer with strong capability in research, development and manufacturing, you can not only get the factory price but also can enjoy the "ultra-high quality and professional design" unique to Zhongjiluyuan.

2. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Jining City, Shandong Province, China. You can visit us by air to Qufu airport, or by the high-speed rail. All the customers, from home or abroad, are warmly welcome to visit us!

3. Q: Can you do OEM?

A: Yes, we can do OEM as client's requirement.

4.Q: All products have a warranty?

A:YES, Our warranty term is One Year.

5.Q:What about the delivery time?

A:Usually3-10 days after down payment, the exact delivery time is according to the production season and order quantity.

6. Q: What is the biggest advantage of the company?

A: Stable Better Quality and Perfect Service .

Our company is a state high-tech enterprise, our rebar processing machinery are used in hundreds of infrastructure projects both with China and abroad. We have the most complete after-sales service support system ,"8-level quality assurance system," truly lifelong maintenance,customer satisfaction is almost 100%.