Пескоструйная машина вертикальный вал ударная Дробилка камня для производства

- Категория: Sand Making Machinery >>>

- Поставщик: Zhengzhou,Tianyu,Heavy,Industry,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 8147068.76 $* | 8554421.74 $* |

| Aug-18-2025 | 8078606.62 $* | 8482536.52 $* |

| Jul-18-2025 | 6777813.8 $* | 7116704.13 $* |

| Jun-18-2025 | 7941680.36 $* | 8338764.23 $* |

| May-18-2025 | 6914739.46 $* | 7260476.65 $* |

| Apr-18-2025 | 7804755.76 $* | 8194993.0 $* |

| Mar-18-2025 | 7736292.63 $* | 8123107.64 $* |

| Feb-18-2025 | 7667829.6 $* | 8051220.37 $* |

| Jan-18-2025 | 7599366.48 $* | 7979334.23 $* |

Характеристики

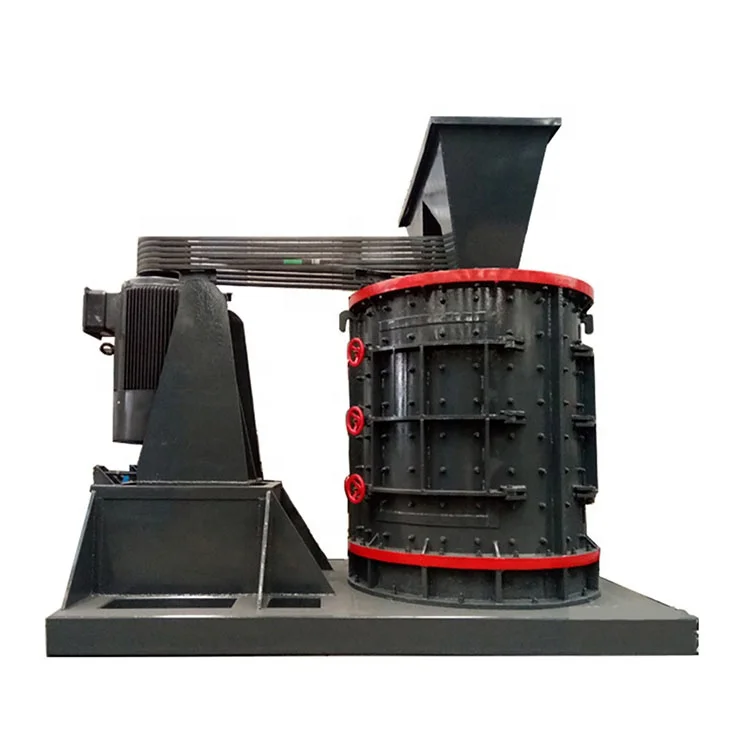

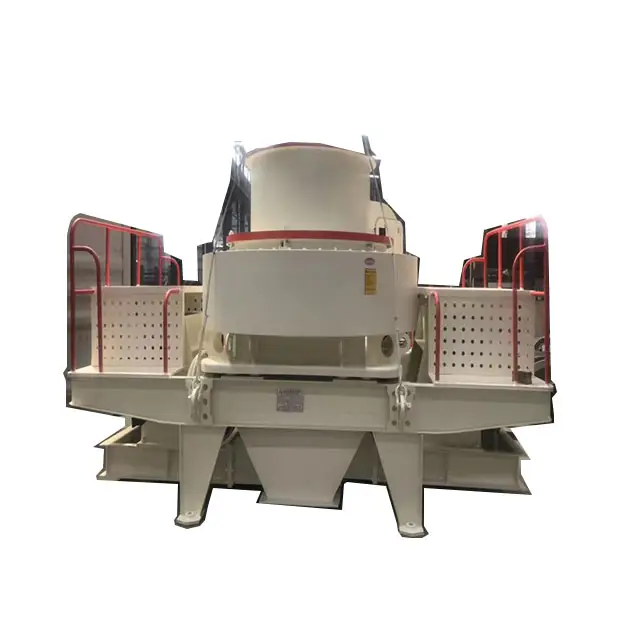

Product Name:Sand Maker Vertical Shaft Impact Rock Stone Crusher Sand Making Machine

Vertical plate hammer sand making machine belongs to a traditional small sand making machine, also called vertical sand making machine, plate hammer sand making machine, vertical axis plate hammer sand making machine, composite sand making machine, etc. It is a kind of fine crushing equipment without sieves, mainly suitable for limestone, clinker, coal, and other materials whose compressive strength does not exceed 140 MPa and humidity is not more than 15%. Sand making equipment is very common in small sand and stone factories.

Features and advantages of sand maker vertical shaft impact rock stone crusher sand making machine

1:The breaking ratio is large. Its feed particle size is 5-100mm, and it can produce 0-5mm sand with a large crushing ratio. The design of the plate hammer adopts the rigid connection mode, which can obtain greater speed and kinetic energy and improve the processing capacity of the equipment.

2:Good crushing performance. The rotor adopts a new design structure, which adopts the steel disc structure of the impact crusher and the hammer disc structure of the hammer crusher. Its structural design effectively enhances the crushing performance and improves the production efficiency. No screen strip setting, crushing materials with a large amount of sediment will not be blocked, unbreakable materials can be automatically discharged into the machine body, and will not cause damage to the equipment.

3:The equipment is durable and has a low failure rate. The wearing parts are made of high-hardness, high-toughness multi-element alloy wear-resistant materials. At the same time, they adopt a new combined hammer head structure design, which is more conducive to hammering and crushing of materials, greatly improving the life of the hammer head and effectively reducing production costs. Reduce the impact of equipment downtime. Moreover, the structural design is convenient, and the wearing parts can be easily replaced by opening the working warehouse door.

4:Environmental protection and energy saving. The equipment is equipped with a dustproof board, which has good sealing performance, avoids the splashing of small materials after crushing, less dust, low working noise, and effectively improves the working environment on the construction site.

There are multiple hammers in the CNC vertical shaft sand making machine. After the material enters the crushing chamber, it is hit by the high-speed running hammer head. Under the action of the high-speed rotating impeller centrifugal force, the material produces high-speed impact and crushing. The impeller and the casing are collided with each other multiple times, rubbed and crushed, and discharged directly from the lower part, forming a closed circuit multiple cycles, and controlled by the screening equipment to achieve the required particle size of the finished product.

| Model | Barrel diameter (mm) | Capacity (t/h) | Feeding size (mm) | Discharging size (mm) | Motor power (kw) | Dimensions (mm) | Weight (t) |

| PFS-800 | 750 | 10 - 20 | <100 | 10-120 adjustable | 30 | 2100×1200×1700 | 4300 |

| PFS-1000 | 1000 | 20-40 | <120 | 10-120 adjustable | 55 | 2600×1400×1900 | 6200 |

| PFS-1250 | 1250 | 40-60 | <150 | 10-120 adjustable | 90 | 2800×1600×2100 | 8500 |

| PFS-1500 | 1500 | 80-100 | <180 | 10-120 adjustable | 132 | 3100×1900×2200 | 13700 |

| PFS-1750 | 1750 | 130-160 | <200 | 10-120 adjustable | 160 | 3710×2360×2390 | 20200 |

| PFS-2000 | 2000 | 200-250 | <220 | 10-120 adjustable | 185 | 4100×2660×2620 | 24500 |

Q:Can I order the product with special size?

A:Of course you can, also we will produce the products according to your detail requests.

Q: Do you supply oversea service?

A: Yes, we do. Engineers available to service overseas.

Q: How about the warranty?

A: We will supply you one year warranty and lifelong technical support.

Q: Why we are your best choice?

A:We have direct factory and many years of export experience, and offer the best price with high quality product, timely delivery, also have good after-sales service, therefore with good reputation on boards and with many clients have good long-term business relationship.