Новый завод по переработке убойных отходов 2 тонны с

- Категория: Экологическая техника >>>

- Поставщик: Shandong,Tinwing,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.32 $* | 0.35 $* |

| Aug-15-2025 | 0.20 $* | 0.63 $* |

| Jul-15-2025 | 0.77 $* | 0.45 $* |

| Jun-15-2025 | 0.89 $* | 0.6 $* |

| May-15-2025 | 0.54 $* | 0.11 $* |

| Apr-15-2025 | 0.38 $* | 0.76 $* |

| Mar-15-2025 | 0.68 $* | 0.6 $* |

| Feb-15-2025 | 0.54 $* | 0.41 $* |

| Jan-15-2025 | 0.57 $* | 0.14 $* |

Характеристики

Product Description

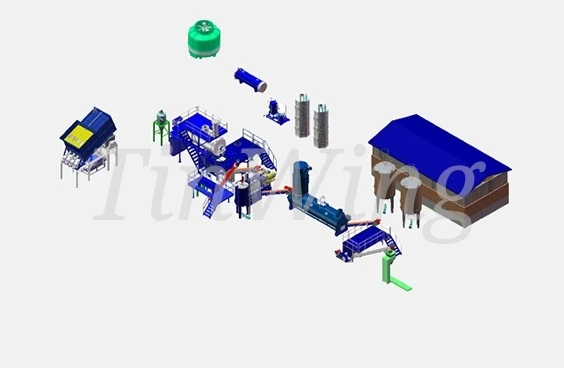

New developing slaughter waste rendering plant 2 ton unit with workshop

Our Machine's Introduction:

Our poultry waste rendering process line machine owns the characters as followed:Full-automatic control, instant handling speed, thorough sterilizing effect, scientific and environmentally protective process,100% free from extraneous odor and no second pollution. The output material will bring high profit both in the society and economy. It’s the most popular and approved handling style internationally.

Technological process

material

→crush

→cooking/dry

→press

→powder

→ pack

Simple process introduction

Dry cooking-treatment is a technology that cooks the dead/diseased animals for sterilization and melting the meat in a closed high-pressure jacketed cooker, heated by circulated steam going into interlayer of the cooker, and the steam is not in direct contact with the carcasses. The raw material (carcass, or waste) under the condition of high temperature ≥140℃ and high pressure ≥ 0.5MPa, lasting for 4 hours, is converted into organic fertilizer or fuel. Meanwhile, VOCs (volatile organic compounds) generated during the processing will be treated to reach national discharging standards.

Inputting System:

When the collecting truck sends the material in front of the storage door, the storage door will open automatically. Then the raw material will slide into the storage. The raw material will be sent into the pre-crusher through screw conveyor .And the dead animal will be crushed into less than 5mm material in the function of high-speed crush.

Pre-breaker

The Pre-breaker is especially designed or size reduction of complete carcasses of cattle , horses and pigs as well as all sorts of offal and bones from slaughterhouses. The pre-breaker is installed as the first stage of a rendering plant , always doing the hard work before crushers and mincers for final grinding if necessary . All knives and anvils are hard faced .

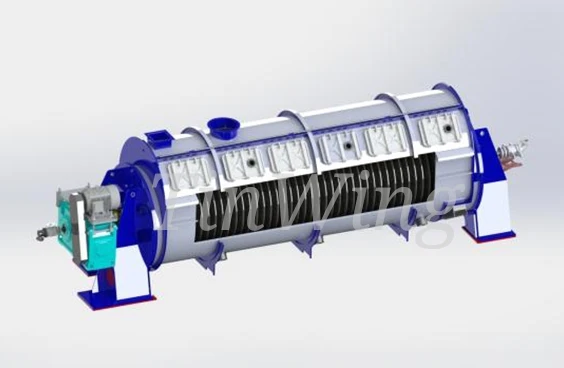

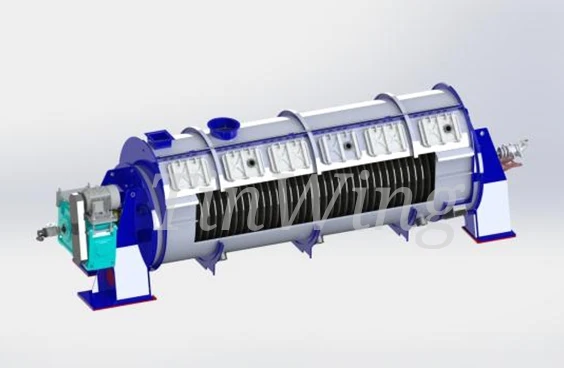

Batch Cooker

Oil Press

With thick steel plate , more durable .

A variety of models , suitable for different processing capacity of customers .

Handing large quantities , occupy a small workshop area . Small power consumption , easy to operation , management and maintenance Low residual oil press cake , good oil quality , the processed cake is loose and not fragile .

A variety of models , suitable for different processing capacity of customers .

Handing large quantities , occupy a small workshop area . Small power consumption , easy to operation , management and maintenance Low residual oil press cake , good oil quality , the processed cake is loose and not fragile .

Cooker type | Capacity(kg/batch) | ||||||

Mixed meat offal,bones | Raw blood | Wet feathers | Mixed poultry offal | ||||

XBC5000 | 3000 | 2000 | 2700 | 3000 | |||

XBC6500 | 4000 | 2500 | 3500 | 4000 | |||

XBC8500 | 5000 | 3400 | 4600 | 5000 | |||

XBC10000 | 6000 | 4000 | 5400 | 6000 | |||

XBC16000 | 10000 | 7000 | 9000 | 10000 | |||

Other auxiliary equipment

Packing&Shipping

Packaging Details | Standard packing of Poultry waste rendering plant | ||||||

Port | Qingdao | ||||||

Lead Time | Shipped in 45 days after payment | ||||||

We usually pack our products by standard export cartons as master carton. We always choose the best and safe packaging material to make sure your orders won't be damaged during delivery.

Company Introduction

Shandong TinWing Machinery Manufacturing Co.,Ltd.is a professional manufacture of food processing machine and pressure vessel,inculding sterilization autoclave,jacketed pot,vacuum cooling machine,modified atmosphere packaging machine,vulcanization

tank,autoclave,animal waste rendering plant,feather meal production line,fish meal production line,wood processing machine etc. We have many years’ experience in this industry.

We can produce the machine according to your requirement and production.Please don't

hesitate to contact me if you have any question or you are interested in any of our equipment,

we will offer the best service to you within 24 hours.

Welcome to visit our company at any time and thanks for visiting our website!

tank,autoclave,animal waste rendering plant,feather meal production line,fish meal production line,wood processing machine etc. We have many years’ experience in this industry.

We can produce the machine according to your requirement and production.Please don't

hesitate to contact me if you have any question or you are interested in any of our equipment,

we will offer the best service to you within 24 hours.

Welcome to visit our company at any time and thanks for visiting our website!

Our Workshop

Our Customer

Certifications

FAQ

1.What are the payment terms?

TT,L/C and trade assurance are acceptable,TT will be more appreciated,30% deposit before production,70% balance before shipment.

2.What is the delivery time?

At least 2 month after the deposit recipit,depend on how many machines included in the line.

3.How to pack the machine?

Standard packaging

4.How to install after the machines arriving destination?

Our engineer will go to customers site if you need,but need to pay installation fee accord with the contract.

5.What's the capacity you can do?

We always produce depend on customers' requirement.

TT,L/C and trade assurance are acceptable,TT will be more appreciated,30% deposit before production,70% balance before shipment.

2.What is the delivery time?

At least 2 month after the deposit recipit,depend on how many machines included in the line.

3.How to pack the machine?

Standard packaging

4.How to install after the machines arriving destination?

Our engineer will go to customers site if you need,but need to pay installation fee accord with the contract.

5.What's the capacity you can do?

We always produce depend on customers' requirement.

Contact

SHANDONG TINWING MACHINERY MANUFACTURING CO.,LTD

NAME:Jerry

E-mail:jerry@xzdjx.com

Tel:+86-18766363705

www.sensitar.com

Address:Xiangzhou Industrial Park,Zhucheng City,Shandong Province

NAME:Jerry

E-mail:jerry@xzdjx.com

Tel:+86-18766363705

www.sensitar.com

Address:Xiangzhou Industrial Park,Zhucheng City,Shandong Province