Печь для вакуумной очистки с флюидизированным покрытием по заводской

- Категория: Metal & Metallurgy Machinery >>>

- Поставщик: Yancheng,DragonPower,Electric,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 952.32 $* | 1000.26 $* |

| Aug-15-2025 | 944.12 $* | 991.42 $* |

| Jul-15-2025 | 792.20 $* | 832.10 $* |

| Jun-15-2025 | 928.68 $* | 974.38 $* |

| May-15-2025 | 808.73 $* | 848.25 $* |

| Apr-15-2025 | 912.40 $* | 958.47 $* |

| Mar-15-2025 | 904.63 $* | 949.65 $* |

| Feb-15-2025 | 896.32 $* | 941.21 $* |

| Jan-15-2025 | 888.26 $* | 932.21 $* |

Характеристики

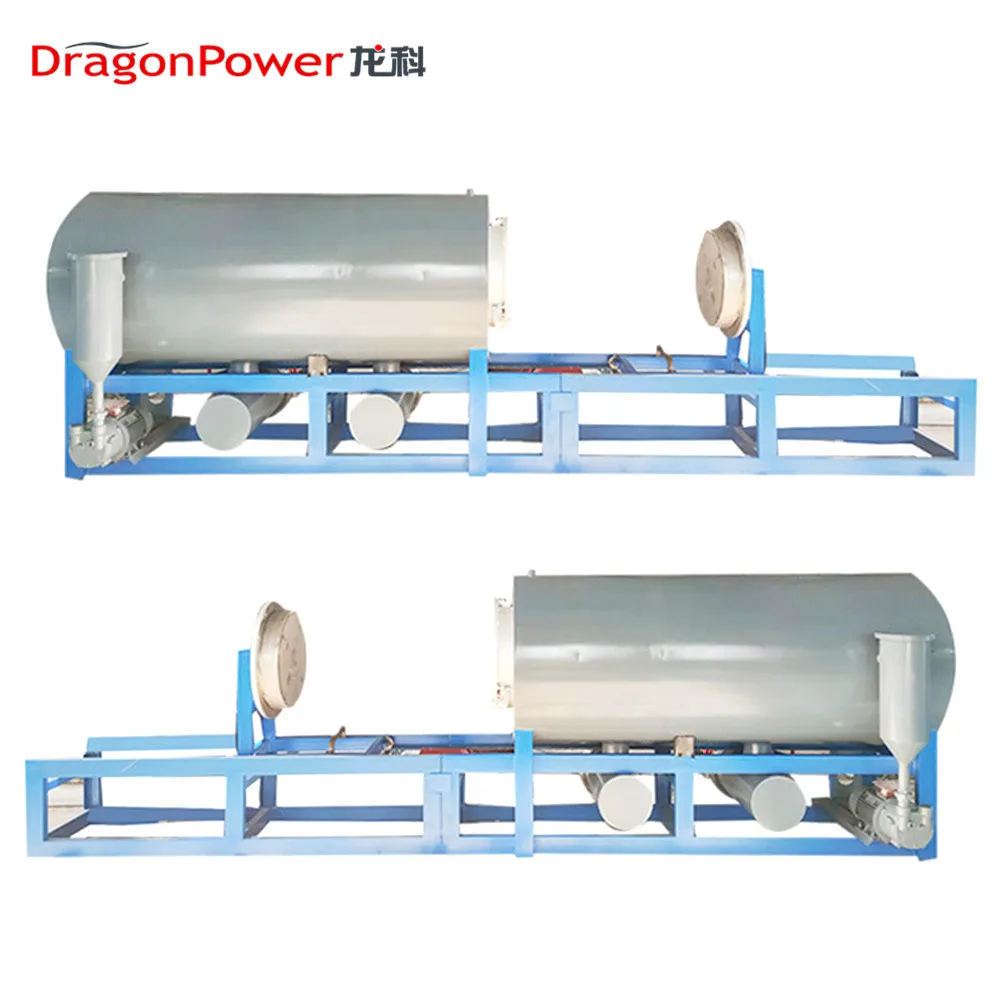

DragonPower vacuum cleaning furnace (also known as vacuum calciner) is suitable for cleaning and processing of chemical fiber industry, nylon and polypropylene production components, spinnerets and filter elements, as well as plastic extrusion mold, cable and textile industry.

DragonPower vacuum cleaning furnace adopts high temperature resistant seal ring, no water cooling protection, so, the device heating power is small, high thermal efficiency, heating speed, temperature uniformity is good, heater inspection and maintenance is convenient, more than the furnace out-of-band heater heating and saving electricity, more water-saving, Moreover, it overcomes the defects of poor temperature uniformity and bad local cleaning effect caused by water cooling.

![I043L`W~$LC`8VF]LBIGH)T.png](https://sc02.alicdn.com/kf/Hc86e629703224b63ab0b3a1b5487f641t/231855089/Hc86e629703224b63ab0b3a1b5487f641t.png)

Type | Model | Guard size (mm) (L*W*H) | External size (mm) (L*W*H) | Power (KW) Heat/vacuum mercury | Water consumption (m3 /h) |

Vertical type | LK-QXLL | φ500×600 | 2000×1800×2100 | 18/2.2 | 0.23 |

LK-QXLL | φ600×800 | 2200×2000×2200 | 21/2.2 | 0.23 | |

LK-QXLL | φ800×1000 | 2600×2300×2500 | 27/3 | 0.28 | |

LK-QXLL | φ1000×1200 | 2800×2500×2700 | 32/2.2 | 0.45 | |

Well type | LK-QXLJ | 1400×400×400 | 1600×1200×1000 | 21/2.2 | 0.28 |

LK-QXLJ | 2200×600×600 | 1800×1300×1100 | 27/3 | 0.28 | |

LK-QXLJ | 3200×600×600 | 2100×1500×1300 | 32/3 | 0.28 | |

LK-QXLJ | 4000×600×600 | 2100×1500×1600 | 36/4 | 0.45 | |

Horizontal type | LK-QXLW | φ500×600 | 2000×1000×1300 | 18/2.2 | 0.23 |

LK-QXLW | φ600×900 | 2400×1100×1600 | 21/2.2 | 0.23 | |

LK-QXLW | φ800×1100 | 2600×1200×1800 | 27/3 | 0.28 | |

LK-QXLW | φ1000×1500 | 2800×1400×2000 | 32/4 | 0.45 |

Cleaning principle:

This equipment utilizes the characteristic of polymer that can be melt at about 300 ℃, be coked and cracked above 300 ℃ under isolation air, and be oxidized in vacuum environment with a small amount of air above 400 ℃. And firstly work pieces with polymer sewage are heated to 300 ℃ (according to the process requirements) so that a large number of high-molecular polymer on the work pieces dissolve and flow into the collection container at the lower part of the furnace, and then the furnace temperature is raised to 400 ℃-500 ℃. While opening the vacuum pump, a small amount of fresh air is added to make the remaining polymer fully oxidized and the carbon dioxide generated is pumped through a ring vacuum pump after water spraying and discharged out of the oven together with water.

Packing: 1.Standard Cartons or Woonden Case 2. As customer's request

Delivery Time: 1. Generally in 7 days after the payment 2. Depend on the item specification, quantity

![XFOLRB]GG%G(9]ZQ%3IE0N.png](https://sc02.alicdn.com/kf/Hb972d3bfc91e45268677a45b2b1f56d5p/231855089/Hb972d3bfc91e45268677a45b2b1f56d5p.png)

DragonPower specializes in producing industrial electric heaters with a strength in R&D. Our products include air cooling & heating system, ceramic heaters, cast aluminum/copper heaters, mica heaters, cartridge heaters, infrared heaters, tubular heaters, immersion heaters, thermocouples, high temperature insulated wires & cables, etc. We provide OEM and design services. The other services we are committed to offer include:

1. Flexibility with minimum order requirements

2. On-time delivery

3. Free replacement if any product quality issues within guarantee period

4. Technical support

5. Simple ordering procedure: Email, fax or mail.

DragonPower had passed ISO9001 and CE certificate. It applies strict test and control over every single part of the products as well as every processing step, ensuring that our products have longer lifetime, better insulation, more even heating and longer thermal inertia.