Одноцелевая солнечная вакуумная трубка

- Категория: Запчасти для солнечного водонагревателя >>>

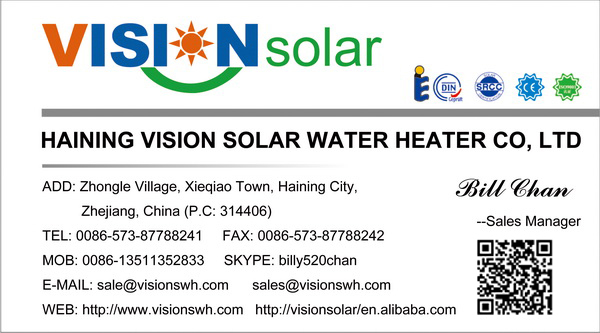

- Поставщик: Haining,Vision,Solar,Water,Heater,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.68 $* | 0.30 $* |

| Aug-15-2025 | 0.32 $* | 0.62 $* |

| Jul-15-2025 | 0.94 $* | 0.46 $* |

| Jun-15-2025 | 0.75 $* | 0.15 $* |

| May-15-2025 | 0.67 $* | 0.50 $* |

| Apr-15-2025 | 0.15 $* | 0.74 $* |

| Mar-15-2025 | 0.84 $* | 0.29 $* |

| Feb-15-2025 | 0.16 $* | 0.2 $* |

| Jan-15-2025 | 0.90 $* | 0.83 $* |

Характеристики

Single Target Solar Vacuum Tube Price VST-T5818

VISION solar vacuum tubes are the heart of the VISION tube solar water heater and solar collector, responsible for absorbing sunlight and converting it into usable heat. The single-target vacuum tube is usually used for direct solar water heating application.

VISION vacuum tubes are made of double layer borosilicate glass, the solar tube is carefully selected with improved hailstone impact resistant and thermal shock resistance. The evacuated tunnel consists of two concentric glass tubes which are sealed in a semicircular shape on one side and are joined to one another on the other side.

The space between the tubes is evacuated and then hermetically sealed, the internal glass tube is coated with an environmentally friendly, highly ‘sensitive’ layer on the outside, thus turning it into an absorber. The coating is protected against adverse weathering influences within the evacuated space, the single-target spattering coating AL/AL-ALN(H)/AL-ALN(L)/ALN is characterized by extremely low emission and excellent absorption.

Technical Data of VISION Single-target Vacuum Tube:

Tube structure | All-glass double-tube co-axial structure | |||

Glass material | High borosilicate 3.3 glass | |||

Outer tube size | Φ=47±0.7mm &=1.6±0.15mm, Φ=58±0.7mm &=1.6±0.15mm, Φ=70±0.7mm &=2.0±0.15mm | |||

Inner tube size | Φ=37±0.7mm &=1.6±0.15mm, Φ=47±0.7mm &=1.6±0.15mm, Φ=58±0.7mm &=2.0±0.15mm | |||

Tube length | 800mm, 1200mm, 1500mm, 1600mm, 1800mm, 1900mm, 2000mm, 2100mm, etc. | |||

Absorber coating | Coating material | AL/AL-ALN(H)/AL-ALN(L)/ALN | ||

Sediment method | Single target magnetron sputtering plating | |||

Absorptivity | as=0.90 ~ 0.93 (AM1.5) | |||

Emission ratio | Eh=0.05 ~ 0.075 (80±5 oC) | |||

Vacuum degree | P≤5.0X10-3 Pa | |||

Stagnation temperature | 220 ~ 260 oC | |||

Average heat loss | ULT=0.6 ~ 0.7 W/(m2* oC) | |||

Pressure-endure | 1.0 Mpa | |||

Hail Resistance | Φ25 mm | |||

Model Number | Tube Size/ MM | Container Loading Quantity (PCS) | ||

20GP | 40GP | 40HQ | ||

VST-T4715 | Φ47*1500 | 4444 | 8889 | 10794 |

VST-T4718 | Φ47*1800 | 3733 | 7467 | 9067 |

VST-T5818 | Φ58*1800 | 2625 | 5250 | 6375 |

Warranty:

15 years international responsibility for VISION solar glass vacuum tube due to original quality problems.

Features of VISION Solar Glass Vacuum Tube:

Tube Design

The vacuum tube design used by VISION was originally developed in the 1980s and has been proven to be extremely robust. Referred to as the "Sydney" tube, "twin-tube" or "all-glass", the tube is essentially two glass tubes that are fused at the top and bottom. The inner tube has a solar absorbing coating, and the space between the two tubes is evacuated to form a vacuum.

Strong Glass

The tubes are made from a type of glass called Borosilicate, the same base material as used in many Pyrex glass products used in kitchens around the world. Borosilicate glass has the characteristic of being very strong and also has excellent light transparency (>94% ) .

The wall thickness of the glass greatly impacts the strength, longevity and naturally also the cost. VISION vacuum tubes are custom made to strict requirements that exceed the industry standards, including a 1.6mm thick wall ensuring excellent strength and resilience to hail impact.

To confirm the strength of the tubes, each batch of evacuated tubes assembled in the VISION factory have randomly selected samples tested by dropping a 30mm / 1.2" diameter steel ball onto the tube from various heights.

Vacuum Insulation

The name "evacuated" is used to describe the process that expels the air from within the space between the tube tubes, forming a vacuum. A vacuum is an excellent insulator against heat loss, and so evacuated tubes are able to operate very efficiently when there is a big difference between the inside of the tube and the outside ambient air. For this reason vacuum tubes are the ideal choice for high temperature hot water applications or locations that get cold in the winter.

Barium Getter

In order to help maintain the vacuum over the 15-20 year life of the vacuum tube, a barium getter "soaks up" any remaining gases in the evacuated chamber plus any fresh gases such as Nitrogen that can slowly permeate through the glass over time, a process known as out-gassing. This barium layer also provides a clear visual indication of the vacuum status; the silver-colored barium layer turns white if the vacuum is lost making it easy to identify a fault tube.

Solar Absorber

The absorber coating comprises a base layer of Aluminum on the outside of the inner glass tube followed by thin layer of the dark colored AL/N material. These coatings are applied using a method called DC reactive sputtering which is extremely reliable after having been fine-tuned over the past 20 years since it was developed.

Efficiency

The combination of the highly efficient absorber coating and the vacuum insulation means that the coating can be well over 200oC / 392oF and the outer glass is cool to touch. In strong sunlight, each vacuum tube can provide over 60 Watts / 204 Btu of water heating output.

Other Tube Designs

There are a number of different structural vacuum tube designs that exist. Such as three-target vacuum tube, Three-target purple tube, Super heat tube, Three-cavity tube, Magnetic vacuum tube, Eccentric vacuum tube, Both-side open tube, Heat pipe tube, Metal-glass heat pipe tube, etc.

Extracting Heat

The heat produced by an evacuated tube can be extracted in a number of ways, depending on the design. The most common methods include direct water flow, U tube pipe, pipe-in-pipe or heat pipe.

Advantages of VISION Vacuum Tube Collector:

Comparing with flat plate collector:

1. Much more economical for solar water heating application;

2. Higher efficiency with much less heat loss in glass tube;

3. Working all year round even in subzero temperatures;

4. Inexpensive tube and easy to maintenance;

5. More convenient in parts carring and installation;

OEM: Your LOGO information can be made on our solar glass vacuum tubes and carton boxes.

ODM: Design can be made according to your requirements such as tube shape and size etc.

Heat Pipe: Please be noted that single target tube can not be used for heat pipe.

Packaging Details: Export strong corrugated carton outside with thick styrofoam protection inside.

Delivery Detail: Within 5 - 7 days for container order quantity upon confirmed invoice or sales contract.

Fast response: Your inquiry will be replied within 24 hours via e-mail or online messenger;

Technical support: You have more than 10 years experience from VISION SOLAR for product suggestion, installation guidance, market analysis, etc.

OEM & ODM: We welcome OEM & ODM requirements for tube size, length, coating, logo making;

Sample checking: In spite of quality control in production, samples will be selected and tested to check prior to delivery;

Minimum order quantity: We offer sample sample manufacturing for customers to check VISION quality and service;

Shipping service: VISION company offers to arrange goods shipment to abroad ocean port or inland site, and if necessary to make goods insurance, customs clearance, etc;

Import certificates: VISION company offers to make Certificte Origin CO, FORM A, FORM E, FORM F, customs certification, etc.

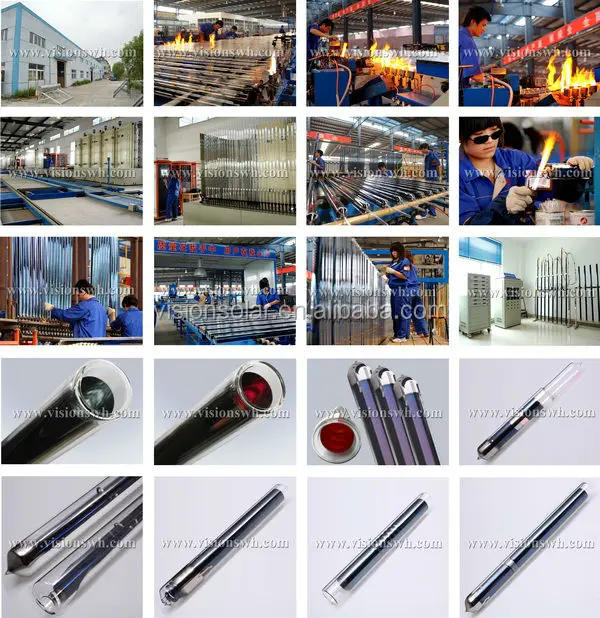

Production & Tube Pictures: