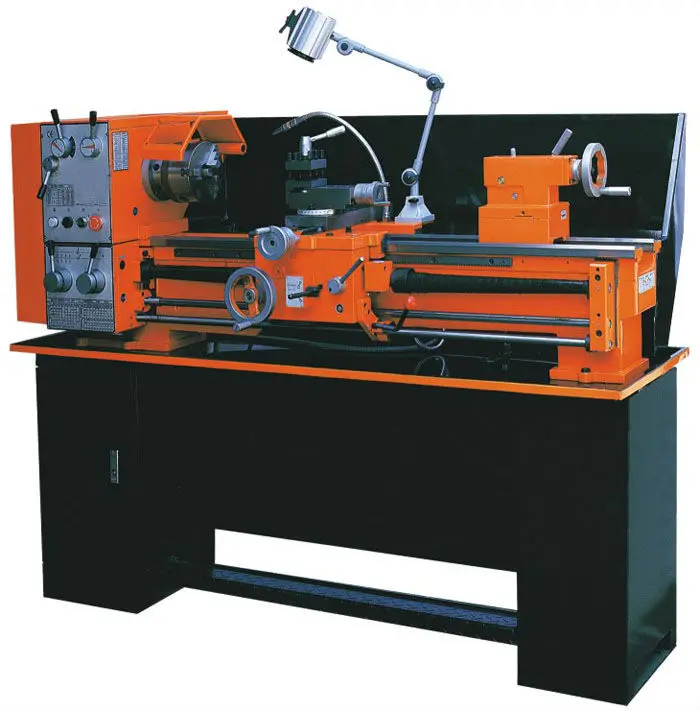

Высокоскоростной точный токарный станок

- Категория: Lathe >>>

- Поставщик: Extreme,Machinery,Manufacture,Co.,Ltd.,(Jingjiang)

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 273141.10 $* | 286798.63 $* |

| Aug-16-2025 | 270845.1 $* | 284387.13 $* |

| Jul-16-2025 | 227235.38 $* | 238597.0 $* |

| Jun-16-2025 | 266255.67 $* | 279568.79 $* |

| May-16-2025 | 231825.6 $* | 243416.45 $* |

| Apr-16-2025 | 261664.94 $* | 274747.3 $* |

| Mar-16-2025 | 259369.9 $* | 272337.96 $* |

| Feb-16-2025 | 257074.39 $* | 269928.62 $* |

| Jan-16-2025 | 254778.26 $* | 267517.67 $* |

Характеристики

L2415LG high speed precision lathe

Feature

·Precision ground and supersonic frequency hardened bed ways.

·The spindle is supported with precision roller bearing.

·Headstock gears are made of high quality steel, ground and hardened.

·Removable gap is provided for larger diameter work.

·Easy operating gear box has various feeds and thread cutting function.

Main specification

|

Model |

L2415LG |

|

Max.swing over bed |

410mm |

|

Max.swing over carriage |

255mm |

|

Over gap |

580mm |

|

Center height |

205mm |

|

Maximum turned length |

1000mm |

|

Width of bed |

250mm |

|

Size of tool(W |

20x20mm |

|

Max.travel of cross slide |

210mm |

|

Max.travel of top slide |

140mm |

|

Spindle bore |

52mm |

|

Spindle bore |

D1-6 |

|

Taper of spindle bore |

MT6 |

|

Range of spindle speed |

16changes 45-1800r/min |

|

Diameter of ball screw |

4T.P.I |

|

Inch threads range |

2-72 T.P.I |

|

Metric threads range |

0.2-14mm |

|

Inch longitudinal feeds range |

0.002"-0.067"/rev |

|

Metric longitudinal feeds range |

0.05-1.7mm/rev |

|

Inch cross feeds range |

0.001"-0.0335"/rev |

|

Metric cross feeds range |

0.025-0.85mm/rev |

|

Moudle threads range |

0.3-3.5M.P |

|

Diametral threads range |

8-44D.P |

|

Max.Traverse |

120mm |

|

External diameter |

50mm |

|

Taper of bore |

MT4 |

|

Power of main motor |

4P/8P.3PH.3.3/2KW(4.5/3KW OPTIONAL) |

|

Power of pump |

4P,3PH 90W |

|

Overall dimensions |

1940X850X1320mm |

|

Packing size |

2070x940x1600mm |

|

Net weight/Cross weight |

1550/1760KG |

|

|

|

|

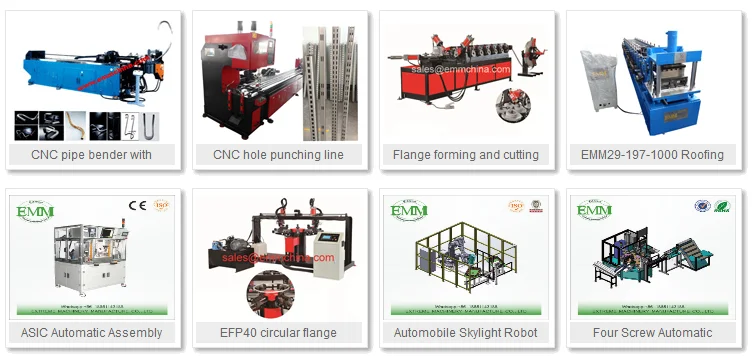

Non-standard automation equipment production workshop |

|

Founded in 2008, EXTREME MACHINERY MANUFACTURE Co., Ltd. Has established long-term cooperation with many enterprises. It is a professional supplier of punching machine, lathe, bending machines, cutting machines, polyurethane equipment, linear punching machines and other metal processing equipment.

|

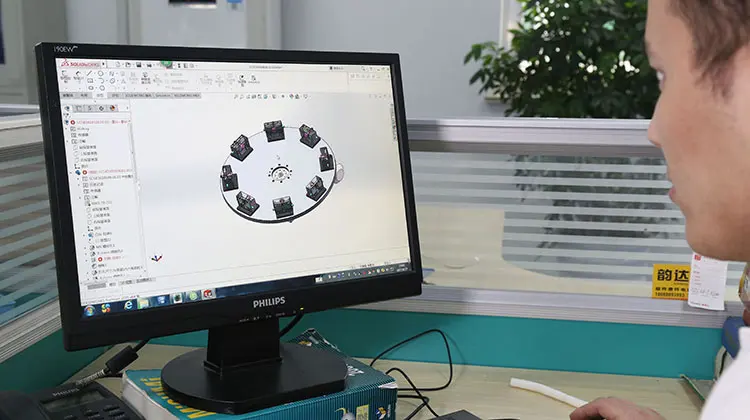

Design office |

Design of non-standard product turntable workpiece |

Dedicate to research and innovation, EMM’s technical team formed long-term cooperation to help enterprises and Shanghai Jiao Tong University, Harbin institute of Technology, Jiangsu University and many other institutions. The company has obtained a number of patents and employed several professionals with Ph.D. degrees. EMM is committed to providing customers with a complete solution in metal processing industry.

|

Meeting |

9 years since its establishment, EMM seizes the opportunity to coordinate all resources and supply good service and professional metal processing machinery solution to customers. The complete industrial supply chain allows us to offer qualified products to more than 800 partner in the world

|

General Manager of EMM-Joan Wang |

Presale Service

We assist customers in well understanding the product information like features, functions and applications and so on. As for the detailed procuring information or drawings, our professionals will first conduct a careful examination and then recommend the most suitable machines or devise proper schemes for customers. We also provide free samples if necessary.

Service during the Sale

1. We are manned with professional salesmen and technicians to provide the information, technical support and the optimal solutions with high cost performance.

2. Based on the specific requirements of customers and the lead time, we will formulate a rigorous operation process. Through the close cooperation of Commodity Department, Sales Department, Technical Department and the Ocean Shipping Department, we are devoted to timely supplying customers with superior machines.

3. Generally, certain quantity of quick-wear parts will be delivered with the goods. The delivery deadline depends on the specific order, which is usually within 1 to 3 months.

After-Sale Service

1. One year warranty is provided.

2. Customers can send photos or samples for our confirmation once the parts are damaged within the one year warranty. If the parts are not damaged by misoperation, we will reply to customers within 48 hours and provide free parts for replacement. Besides, for the parts out of commission and beyond the

warranty, we only charge for the basic costs of parts.

3. We regularly follow up the service condition of products, and timely analyze and copy with the feedbacks. As for the disputes, we will figure out effective actions to reach mutual satisfaction.

1. What does the low pressure polyurethane foam injection machine can produce ?

Re: Our machine can used for making insulating layer, making memory foam, toys, Imitation wood and some other foam products.

2. What is the payment terms?

Re:

1. 100% by T/T;

2. 30% deposit by T/T,the balance paid by T/T before commodity inspection and before shipment.

3. 30% deposit by T/T, the balance paid by L/C at sight;

4. 100% by L/C at sight;

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com