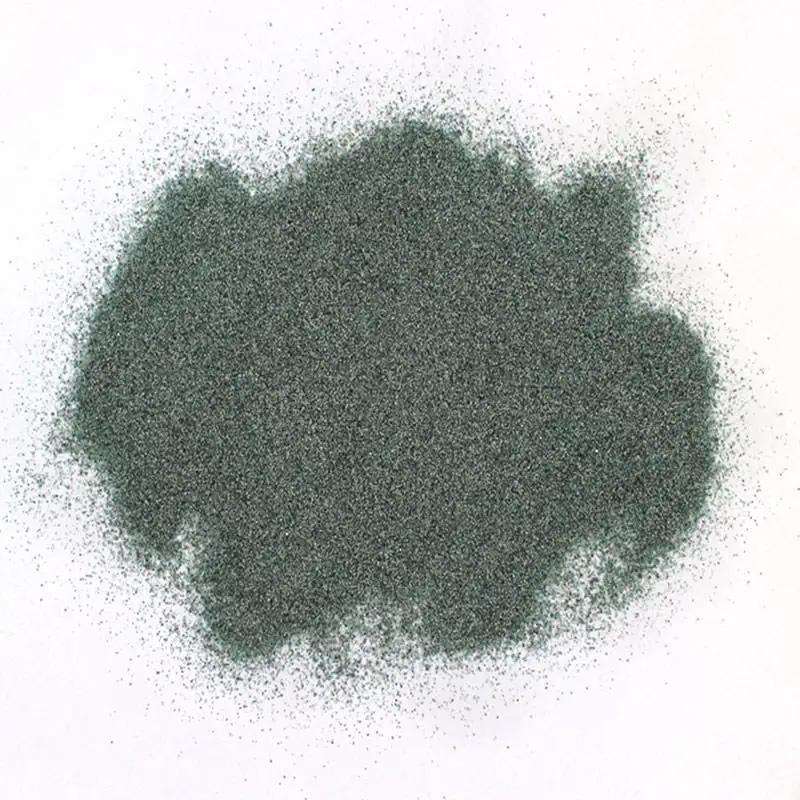

Зеленый карбид кремния/зеленый SIC/кремниевый Карбид для огнеупорных материалов и абразивных материалов/с

- Категория: Abrasives >>>

- Поставщик: Jinan,Enying,Abrasive,Tools,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.50 $* | 0.88 $* |

| Aug-19-2025 | 0.45 $* | 0.29 $* |

| Jul-19-2025 | 0.12 $* | 0.68 $* |

| Jun-19-2025 | 0.72 $* | 0.51 $* |

| May-19-2025 | 0.27 $* | 0.51 $* |

| Apr-19-2025 | 0.58 $* | 0.31 $* |

| Mar-19-2025 | 0.36 $* | 0.89 $* |

| Feb-19-2025 | 0.64 $* | 0.53 $* |

| Jan-19-2025 | 0.41 $* | 0.73 $* |

Характеристики

Green silicon carbide grit is a very hard abrasive material . The hardness of it only ranks after diamond , and it is harder than black silicon carbide. So it is suitable to grinding large range of hard material such as titanium alloy, marble,carbide alloy, optical glasses, ceramics, etc. Green Silicon Carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke. The SiC purity of green silicon carbide is up to 99%min. It is an artificial brittle SiC with high thermal conductivity and high strength which get no decrease in 1000 centigrade.

Green Silicon Carbide (Standard : GB/T2480-2008) | ||||||||

Usage | Green Sic For vitrified wheels | Green Sic For bonded abrasive | Green Sic For flap discs by hand | |||||

Type& Grade | C | C-B | C-P | |||||

NO | Grit No | Chemical composition (%) | ||||||

SiC (≥) | F.C. (≤) | Fe2O3(≤) | ||||||

C | F4-F90 P12-P100 | 98.5 | 0.2 | 0.4 | ||||

F100-F150 P120-P150 | 98.1 | 0.25 | 0.5 | |||||

F180-F220 P180-P220 | 97.2 | 0.3 | 0.55 | |||||

F230-F280 P240-P360 | 97.2 | 0.3 | 0.55 | |||||

F320-F500 P400-P1000 | 97 | 0.35 | 0.6 | |||||

F600-F800 P1200-P1500 | 96.5 | 0.4 | 0.6 | |||||

F1000-F1200 P2000-P2500 | 95.5 | 0.5 | 0.7 | |||||

C-B&C-P | F4-F90 P12-P100 | 98.1 | 0.25 | 0.5 | ||||

F100-F150 P120-P150 | 97.6 | 0.3 | 0.6 | |||||

F180-F220 P180-P220 | 96.7 | 0.35 | 0.65 | |||||

F230-F280 P240-P360 | 96.7 | 0.35 | 0.65 | |||||

F320-F500 P400-P1000 | 96.5 | 0.4 | 0.7 | |||||

F600-F800 P1200-P1500 | 96 | 0.45 | 0.7 | |||||

F1000-F1200 P2000-P2500 | 95 | 0.55 | 0.8 | |||||

Typical Size:

Section sand: 0-1mm, 1-3mm, 3-5mm, 5-8mm

F-macrogrit-sizes-bonded

F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220

Microgrit-sizes-bonded:

240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 3000# 4000# 6000# 8000# 10000#

Section sand: 0-1mm, 1-3mm, 3-5mm, 5-8mm

F-macrogrit-sizes-bonded

F12 F14 F16 F20 F22 F24 F30 F36 F40 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220

Microgrit-sizes-bonded:

240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 3000# 4000# 6000# 8000# 10000#

1. Abrasive: Produce ceramic gring wheel, resinoid gringding wheel, Grinding stone, Gringing block, sand paper, sand cloth, sand belt, polish wax, abrasive paste, coating etc..

2. Sandblasting abrasive: Mainly used for various material workpieces to decontaminate, derusting, prevent corrosion, remove oxide skin etc..

3. Refractory material: Mainly used for abrasion and high temperature resiatant, inoxidizable aggregate and filling of shaped and monolithic refractory in steel metallurgy, various industrial stoves, electric furnace etc..

1.High hardness;

2.High tension;

3.Good self-sharpening;

4.Good thermal stability;

5.High temperature resistance;

6.Anti-corrosion;

2.High tension;

3.Good self-sharpening;

4.Good thermal stability;

5.High temperature resistance;

6.Anti-corrosion;

If you have any question , please do not hesitate to contact with us .