Лидер продаж производственная линия для

- Категория: Pipe Making Machinery >>>

- Поставщик: Hebei,Tubo,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 23760671.33 $* | 24948705.95 $* |

| Aug-19-2025 | 23561001.46 $* | 24739051.31 $* |

| Jul-19-2025 | 19767281.37 $* | 20755645.23 $* |

| Jun-19-2025 | 23161662.7 $* | 24319745.72 $* |

| May-19-2025 | 20166620.34 $* | 21174951.86 $* |

| Apr-19-2025 | 22762323.64 $* | 23900439.38 $* |

| Mar-19-2025 | 22562654.13 $* | 23690787.12 $* |

| Feb-19-2025 | 22362984.82 $* | 23481133.8 $* |

| Jan-19-2025 | 22163315.92 $* | 23271481.32 $* |

Характеристики

Company Profile

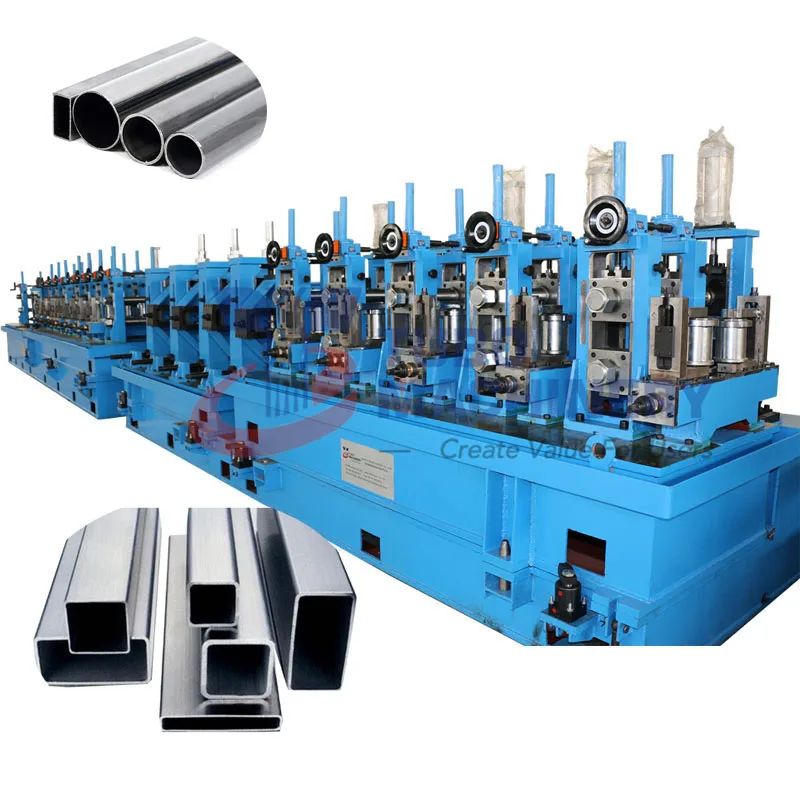

Hebei Tubo Machinery Co.,LTD is a high-tech enterprise registered in Shijiazhuang City. Hebei Province. It specialized in Developing and Manufacturing for the complete set of equipments and related technical service of High Frequency Welded Pipe Production Line and Large-size Square Tube Cold Forming Line . With more than 130 sets all types of CNC machining equipment, Hebei Tubo Machinery Co.,Ltd., manufactures and exported to over 20 countries of welded tube/pipe mill, cold roll forming machine and slitting line, as well as auxiliary equipment for more than 15 years. TUBO Machinery, as a partner of users, provides not only high precision machine products, but also technical support everywhere & anytime.

Which kind of pipe can be produced by our Pipe mill ?

1.Oil & Gas Pipes

2.Wire and Cable Protection Pipe

3.Heating Pipe

4.Structural Support Steel Pipe

5.Low-pressure Process Pipeline

6.Industrial Steel Pipes

7. Low Pressure Fire Fighting Pipeline

8. Decoration Pipe

9. Sewage Pipes

10.Water Pipe

11.Steel Scaffolding Pipe

12. Building pip

Product Specification

Model | Round pipe | Square&Rectangular Pipe | Speed (m/min) | ||

Dia(mm) | Thickness(mm) | Dia(mm) | Thickness(mm) | ||

ERW32 | 10-38 | 0.5-2.0 | 10*10-30*30 | 0.5-1.6 | Max.120 |

ERW50 | 15-51 | 0.5-2.5 | 15*15-40*40 | 0.5-2.0 | Max.120 |

ERW60 | 16-60.3 | 0.5-3.0 | 15*15-50*50 | 0.5-2.5 | Max.120 |

ERW76 | 20-76 | 1.0-4.0 | 20*20-60*60 | 1.0-3.0 | Max.120 |

ERW89 | 25-89 | 1.0-4.5 | 20*20-70*70 | 1.0-3.5 | Max.120 |

ERW114 | 38-114 | 1.0-5.0 | 40*40-90*90 | 1.0-4.0 | Max.80 |

ERW165 | 60-165 | 2.0-6.0 | 50*50-150*150 | 2.0-5.0 | Max.60 |

ERW219 | 89-219 | 3.0-8.0 | 80*80-200*200 | 3.0-8.0 | Max.50 |

ERW273 | 114-273 | 4.0-10.0 | 100*100-250*250 | 4.0-10.0 | Max.40 |

ERW325 | 165-325 | 4.0-12.7 | 100*100-300*300 | 4.0-12.0 | Max.30 |

ERW426 | 219-426 | 5.0-14.0 | 150*150-350*350 | 5.0-14.0 | Max.30 |

ERW508 | 219-508 | 6.0-16.0 | 200*200-400*400 | 6.0-16.0 | Max.25 |

ERW610 | 325-610 | 6.0-18.0 | 250*250-500*500 | 6.0-18.0 | Max.25 |

ERW720 | 355-720 | 6.0-20.0 | 300*300-600*600 | 6.0-20.0 | Max.25 |

Step 1: Uncoiler

Function: support rolled plate and strip tension for erw pipe mill production line, by the frame, main shaft, increases of drum,brake.There are 3 types: pneumatic, hydraulic and manual.

Step 2: Shearing butt welding

2 Types: Automatic & Manual

Function: Shear the end of each strip coil, then welding them together, so that pipe making welding machine line can be continue production.

Step 3: Accumulator

Function: storage strip to keep continue production.

2 Types: Horizontal / Vertical

Advantage: Horizontal type can be larger storage. Vertical type is much cheap and small space occupied.

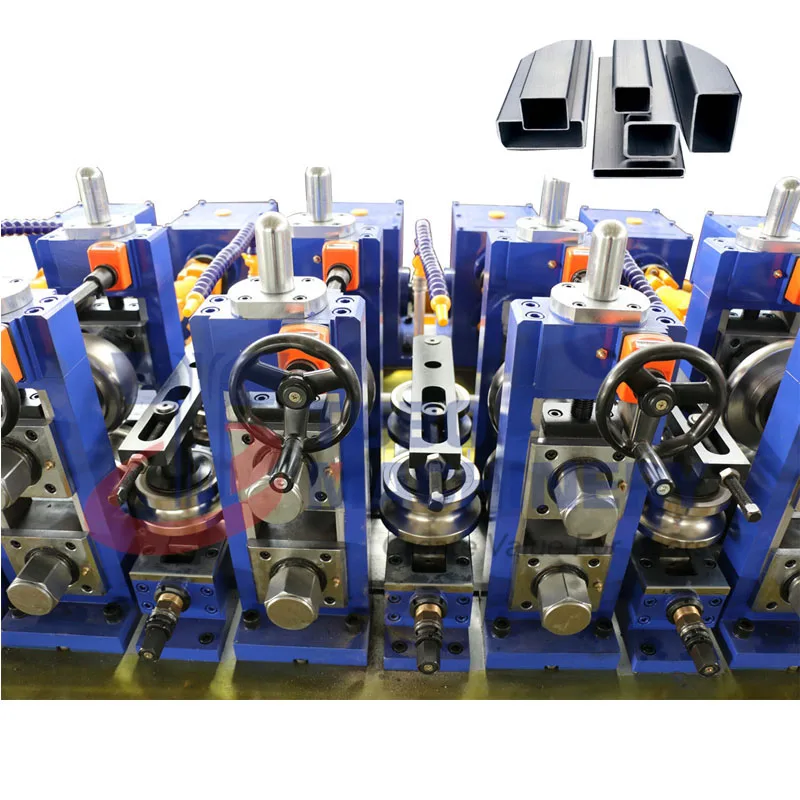

Step 4: Forming Section.

Function: forming the tube from strip

Advantage:

>Advanced forming technical

>One-stage molding platform

>Reliable quality gear box

>Siemens Beide motor

Step 5: High Frequency Welding

Function: Welding the pipe , different thickness & diameter, the power of the HF welding machine welder

Our advantage: We choose the China best welder

Step 6: Sizing Section

Function: sizing the tube to precise size

Advantage:

>Advanced sizing technical

>One-stage molding platform

>Reliable quality gear box and Siemens Beide motor

>High precision, low error of the pipe size

Step 7: Flying saw / Cold Saw

Function: cutting the tube mill line tube to right length.

Fly saw: easy to operation, low investment.

Cold saw: no noise, no burr cutting precision and cross section.

Step 8: Run Out Table & Stacking Machine

Function: For output and packaging of products

2 Types: Automatic,Manually

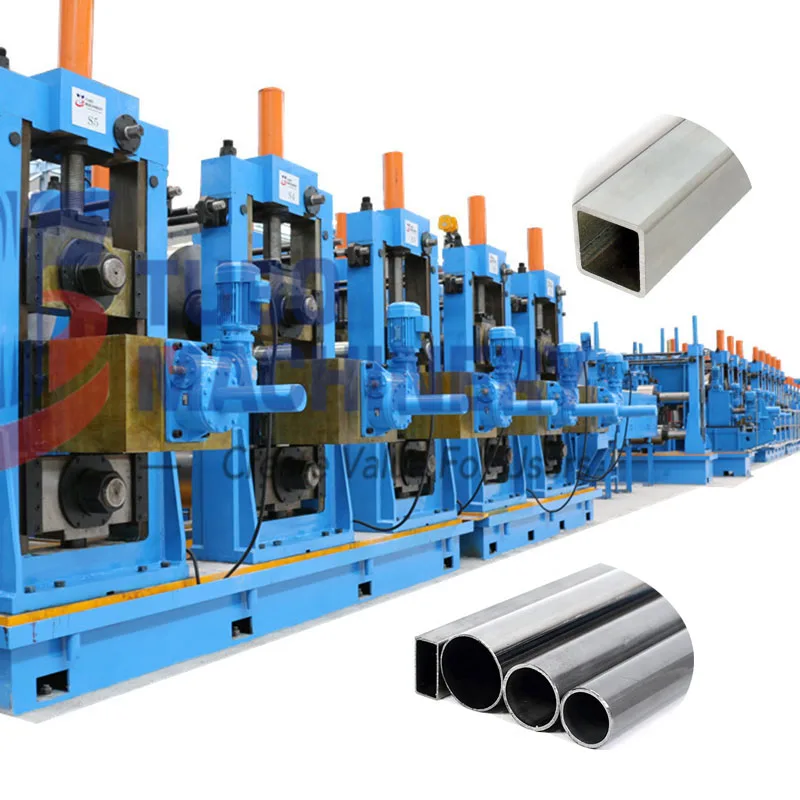

Successful Project

1.In 2020. Chongqi,China.

ERW300x300x16mm, Direct Square Forming Technology,

With cold roll forming producing function.

2.In 2020.Guangdong,China.

ERW300x300x14mm, Direct Square Forming Technology,

Motor Adjusting

3.In 2020. Shandong,China.

ERW200x200x10mm,YS700MPa, Direct Square Forming Technology,

Motor Adjusting.

4.In 2019,Argentina.

ERW203/160x160mm. FFX + Direct Square Technology.

Fully Siemens Automatic Size Changing System. The Best Roller Share-Use Technology for Round+Square pipes.

5.In 2020,Uzbekstan.

ERW76mmUpgrading for Forming,Welding,Sizing & Flying Saw.

Packing&Shipping

Field Visits