Бетономешалка с низким уровнем шума и потреблением энергии цена

- Категория: >>>

- Поставщик: HeSheng,Heavy,Machinery,(Wuhan),Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 9520.28 $* | 9996.43 $* |

| Aug-19-2025 | 9440.70 $* | 9912.74 $* |

| Jul-19-2025 | 7920.5 $* | 8316.99 $* |

| Jun-19-2025 | 9280.87 $* | 9744.99 $* |

| May-19-2025 | 8080.37 $* | 8484.78 $* |

| Apr-19-2025 | 9120.80 $* | 9576.11 $* |

| Mar-19-2025 | 9040.22 $* | 9492.8 $* |

| Feb-19-2025 | 8960.90 $* | 9408.22 $* |

| Jan-19-2025 | 8880.87 $* | 9324.92 $* |

Характеристики

JS1000 Large Capacity Self Loading Forced Concrete Mixer Machine

Performance advantage:

1.JS1000 forced mixer has the characteristics of convenient control of water addition, large mixing force, low power consumption and strong power. The built-in vortex mixer can prevent materials from settling in the warehouse.

2.The main shaft of the double horizontal shaft forced mixer is immersed in sand and gravel cement materials with strong friction for a long time during mixing. If there is no effective shaft end seal, the main shaft is easy to be worn and damaged, resulting in serious slurry leakage and affecting the grading.

3.HSHM-JS1000 mixer is a self-developed multiple shaft end sealing protection technology, which can effectively prevent mortar leakage. At the same time, the automatic lubrication system transmits lubricating grease, and the grease pressure ensures the long-term reliability of shaft end sealing.

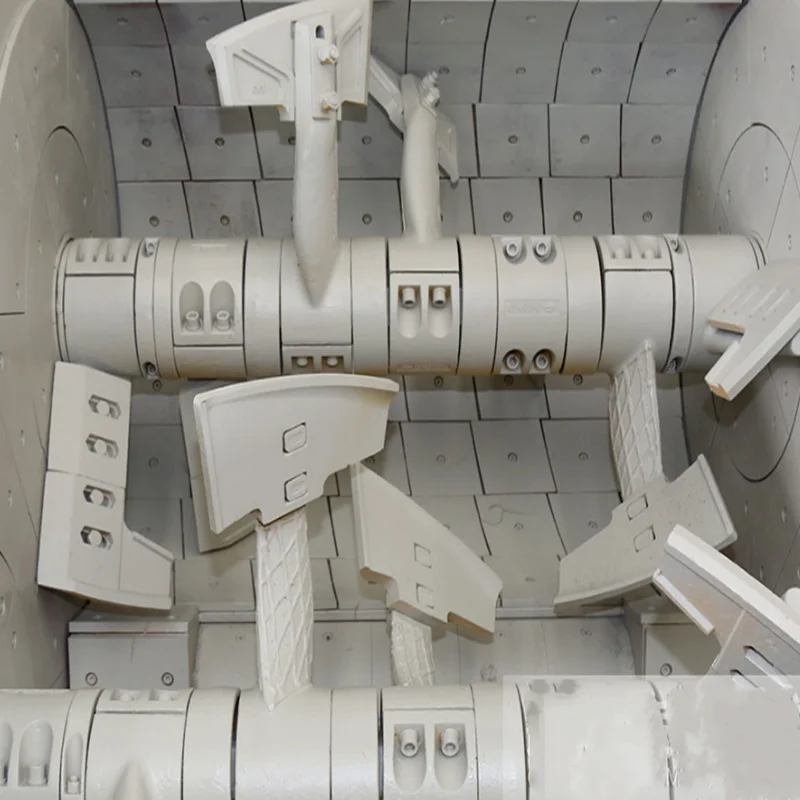

4.The lining plate of JS1000 double horizontal shaft forced mixer includes arc lining plate and end lining plate. The arc lining plate is high chromium wear-resistant alloy, and its performance meets the provisions of JG / t5045.2-93 (HRC ≥ 54, impact value ≥ 7.0n. M / mm2). The end lining plate is made of high-quality high manganese wear-resistant steel plate.

Model | Specification | |

JS1000 | Output Capacity | 1000 |

Feed Capacity | 1600 | |

Theoretical production (m3/h)(based on mixing plant) | ≈60 | |

Maximum aggregate size(pebble/gravel) | 85 | |

Work cycle time(s) | 72/60 | |

Overall weight(kg) | 8700 | |

Overall Dimension(L×W×H)mm | 4320*2200*3300 | |

Mixing blade (speed/quantity) | 29.6r/min 2*8 | |

Mixing motor(model/power) | Y180M-4/2*18.5 | |

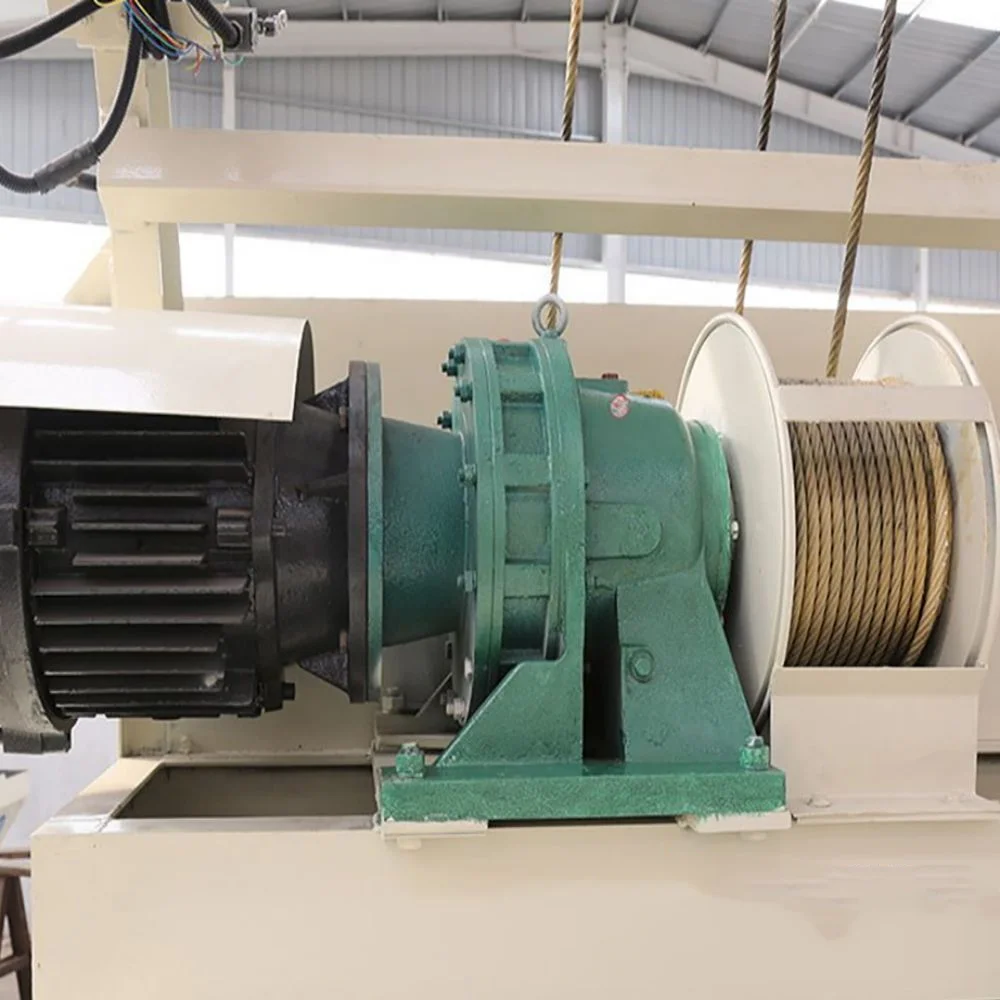

Winch motor(model/power) | YEZ160L-4/15 | |

Water pump motor(model/power) | 80JDB-45/3 | |

Core Components: | Motor, Pump, Mixing shaft, Mixing liner, Mixing Blade | |

“High stability”Mixing system:Low energy consumption,low noise;Automatic control,the liner adopts trapezoidal design;The blades are made of high wear-resistant alloy cast iron to avoid the sticking problem of mixing powder.Stirring speed is fast and uniform.

Reducer:Planetary gear reducer or cycloid gear reducer can be installed;Planetary gear:through the belt transmission,can avoid damage to other parts;Cycloid gear:through the transmission of the impact of the gear,can produce a powerful power to drive the machine.

Electrical system:Motor control parts are in the electric box;Small power consumption,strong power;Safe and reliable,easy to operate and maintain.

Packaging & Delivery:

Overseas Cases:

HSHM is a young and dynamic company specialized in making good machines for building materials industry.

Our main products are concrete bricks & block making machines and auxiliary equipment, from batching plant, mixer, stacker, to auto pallet feeder and auto loading and unloading system, auto packing system, artificial curing system.

HSHM also can provide one-stop turn key solutions for full automatic concrete bricks and block making plant, aerated autoclaved concrete plant, sand-lime bricks making plant and other light weight walling board production line. We offer our customers technologically first-class quality products, creative design services and sound service for optimum, economic production processes. With over 15 years experience's R&D team in concrete bricks making machinery field, HSHM's applied technology service will help you to improve your performance. All our products are synonymous of power and stability, always provide the innovative solutions for complex issues.

Certification:

Our Service:

Before order: Answering Customers' Questions: According to our customer's question by email or telephone, we will provide a patient customer' service. For example: In the beginning of communication, customers will consulting some details about our pellet machine or our company, and we will provide a professional answers for customers understand us better solution just for our customers condition. Design Drawings: We will design drawings for customers' reference. Making offer: According to customers purchase quantity, making a good offer with details solutions.

After order: Delivery Time: After signing the contract and receiving the deposit, the production will take 15~30 working days. Order Tracking: After the deposit received, there will be a professional team tracking the order from production to package and shipment.

After-sale Service: Warranty Period: We provide 12 month warranty for main body. Within 12 month, there is any quality problem with the main body(not including the wearing parts), we will arrange our professional engineers to provide requirement service.

Installation Service: If customers don't need our engineers for installation, we will provide Remote Advisory Services. Also we could arrange engineers to provide installation service if customer need.