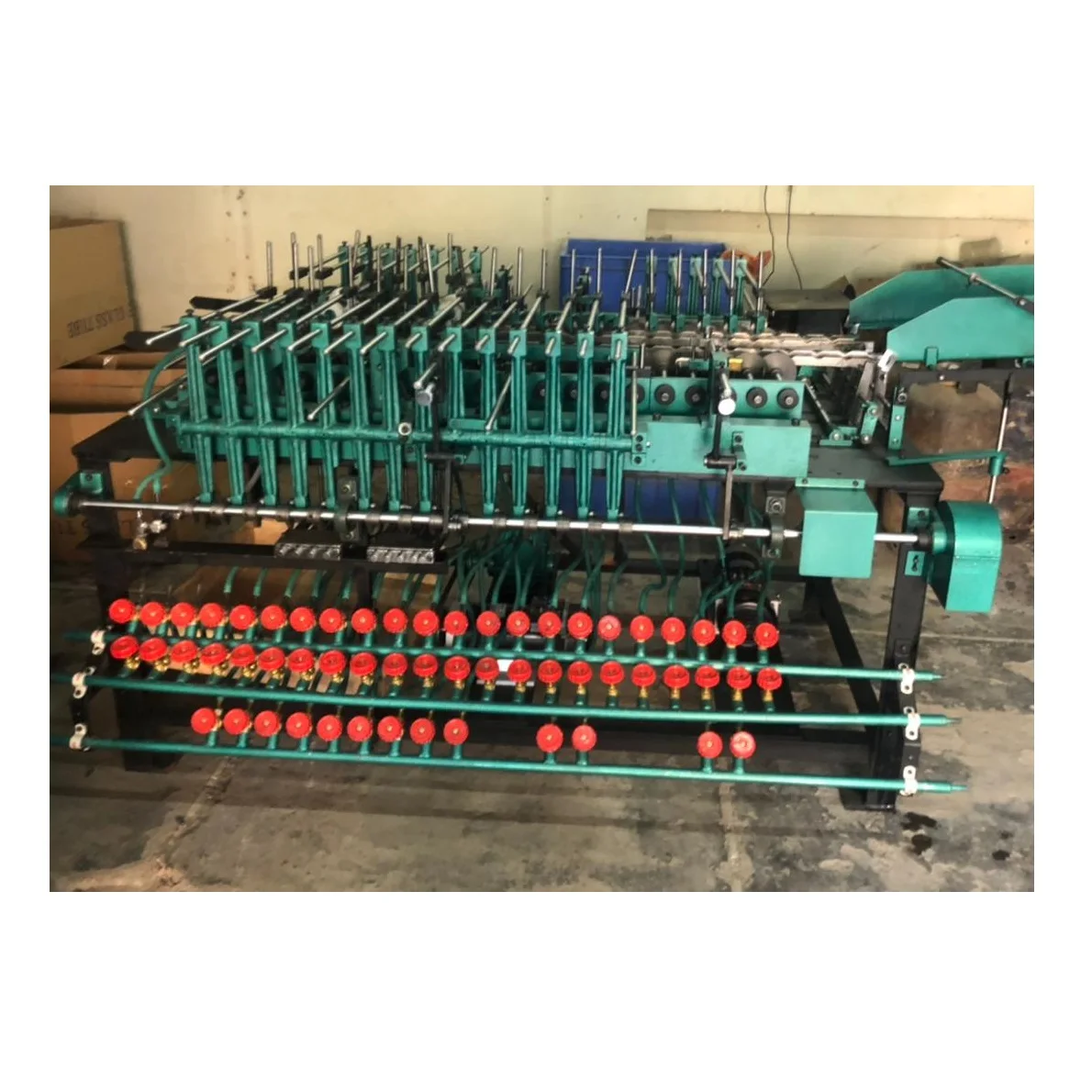

Автоматическая Строительная испытательная трубка делая машину индийская новая технология алюминиевые трубы из нержавеющей стали ключевые производственная

- Категория: Pipe Making Machinery >>>

- Поставщик: SCIENTICO

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 3473240.7 $* | 3542705.24 $* |

| Jul-16-2025 | 2816880.71 $* | 2873218.41 $* |

| Jun-16-2025 | 3418544.91 $* | 3486915.18 $* |

| May-16-2025 | 3391195.70 $* | 3459019.37 $* |

| Apr-16-2025 | 2707487.72 $* | 2761637.5 $* |

| Mar-16-2025 | 3336499.32 $* | 3403229.45 $* |

| Feb-16-2025 | 3309150.5 $* | 3375333.46 $* |

| Jan-16-2025 | 3281802.62 $* | 3347438.12 $* |

Характеристики

Products Description

Machine is Right hand to Left hand automatic operates after manual settings.

* Two motors inbuilt in this machine.

Each motor of one hp ( DC ).with Dc drives.

Easy to functioning.

With the help of dc drive we can regulate the speed of whole machine where we need

According to piece size we make.

* One motor operates machine’s middle shafts or spindles with gear chain, which is rolls the glass tube on wheels.

And one motor operates machine’s whole cams or camshaft; .this function of machine is using to drop the piece to next station.

Each motor of one hp ( DC ).with Dc drives.

Easy to functioning.

With the help of dc drive we can regulate the speed of whole machine where we need

According to piece size we make.

* One motor operates machine’s middle shafts or spindles with gear chain, which is rolls the glass tube on wheels.

And one motor operates machine’s whole cams or camshaft; .this function of machine is using to drop the piece to next station.

Total Nineteen stations on machine where machine works to process or make the final piece with the help of burners.

* Whole machine works base on burners or flames.

* To operate burner’s flames machines has valves.

* The Set of Fifty valves inbuilt in machine.

Where

Twenty valves using for Gas.

Twenty valves using for Air

And ten valves using for Oxygen.

* Each station has burner.

* First station to twelth station has single burner.

* Thirteenth station to Nineteenth station has double burner. Because after twelth station the piece divides in two pieces.

* The Set of Fifty valves inbuilt in machine.

Where

Twenty valves using for Gas.

Twenty valves using for Air

And ten valves using for Oxygen.

* Each station has burner.

* First station to twelth station has single burner.

* Thirteenth station to Nineteenth station has double burner. Because after twelth station the piece divides in two pieces.

Four tool post inbuilt in machine.

* First tool post is works on fourth station to make rim of glass tube.

* Second tool post is works on Ninth station to make rim of glass tube.

* Third and Fourth Tool post works on Thirteenth Station to centering the piece when piece is melting for divide in two.

* First tool post is works on fourth station to make rim of glass tube.

* Second tool post is works on Ninth station to make rim of glass tube.

* Third and Fourth Tool post works on Thirteenth Station to centering the piece when piece is melting for divide in two.

Station Functioning.

* Machine’s first five stations is works on one side of glass tube to make rim or without rim.

* Next five stations is works on second side of glass tube to make rim or without rim.

After that

* Machine’s first five stations is works on one side of glass tube to make rim or without rim.

* Next five stations is works on second side of glass tube to make rim or without rim.

After that

Eleventh station to nineteenth station machine works on center of glass tube.

* Eleventh to thirteenth station the piece heats in middle and divides in two on thirteenth station.

* On fourteenth to sixteenth station both sides piece heats.

* On seventeenth station, air function is using to make bulb of glass tube to both pieces.

* Eleventh to thirteenth station the piece heats in middle and divides in two on thirteenth station.

* On fourteenth to sixteenth station both sides piece heats.

* On seventeenth station, air function is using to make bulb of glass tube to both pieces.

* Eighteen and nineteenth is used for Annealing. Not compulse. We gets final Two piece at the end of all procedure. And procedure is continuously running automatic after one time manual setting of machine. Machine needs manual setting changes ifwe change the size of piece we going to make. Each sizes setting is same but different like stoppers, tool centring,burne flames, air pressure to blow bulb on glass tube etc.

Raw Cutting of glass tube.

* We have to need the raw cutting of glass tube to make the complete test tube length’s double.

If we makes the size of 15mm in 150mm length.then we need raw cutting of 15 mm in 300 length to provide machine.

Machine’s Right Hand Side hangs the hopper where we fill the raw cutting of glass tube.

And second side of machine hangs the wooden carry box where machine fill the final product….

* We have to need the raw cutting of glass tube to make the complete test tube length’s double.

If we makes the size of 15mm in 150mm length.then we need raw cutting of 15 mm in 300 length to provide machine.

Machine’s Right Hand Side hangs the hopper where we fill the raw cutting of glass tube.

And second side of machine hangs the wooden carry box where machine fill the final product….

Specification

Brand Name | Scientico |

Type | Pipe Production Line |

Pipe Material | Glass |

Model No | SCG4000 |

Pipe Shape | Round |

Size (Length) | 75 mm to 200 mm. |

Size (Diameter) | 10 mm to 25 mm |

Applicable Industries | Manufacturing Plant |

Company Profile

SCIENTICO supply the most efficient, robust Machines in the worldwide market place today. Our machines are renowned for their strength, reliability & longevity. EMAIL NOW to discuss your machine specification. All of our incinerators are covered by a 12 month unlimited operating hour usage warranty. (ISO:9001, ISO:13485, ISO: 14001 WHO-GMP, CE) accredited ensuring quality throughout our service and business.

Product packaging

Why Choose Us

Banking upon our assiduous team members we are able to cater varied demands of our valued clients in a prompt manner. To live up to famous reputation, we engage in the utilization of modern techniques in compliance with the set industry guidelines. We deliver the offered medical equipment range within the assured time frame.

Our sophisticated infrastructure has enabled us to successfully meet the bulk orders of our clients. We have constructed our infrastructure facility over a wide area of land. It is also segregated into specialized departments such as quality-control, procurement, production, research & development, warehousing, packaging, and many more. In addition to this, we have equipped our infrastructure with hi-tech machines and the most advanced technology in our production unit.

Our Advantages

* High-quality products range

* Advanced production unit

* Easy payment modes

* Timely delivery

* Strict quality control

* Stringent quality tests

* Competitive pricing

* Advanced production unit

* Easy payment modes

* Timely delivery

* Strict quality control

* Stringent quality tests

* Competitive pricing

FAQ

Q.1 What’s the payment you will accept?

A. We usually accept T/T or L/C. Other terms also could be negotiated

Q.2 Why chooses us?

Q.3 How can you guarantee the quality?

A. We will 100% test the goods before delivery. Most welcome of your quality testing team at our warehouse if you want.

Q.4 How long will it take to delivery to my address?

A. The normal delivery time is 30-40 days, depending on which country you are in and the way of Transportation.

Q.5 Do you accept sample order?

A. Yes, sample order can accept.

Q.6 What's package? Can you give me the package according my requirement?

A. We usually packed by standard exported box or carton. And yes we can pack as per your requirement.

.

A. We usually accept T/T or L/C. Other terms also could be negotiated

Q.2 Why chooses us?

A. Well experienced in our field. Our staff of engineers offers high-valued design guidance to assure product performance and efficiency. And our strict adherence to rigorous quality control and tolerance standards lead to easier assembly of finished components at your facility. We always focus on Quality.

Q.3 How can you guarantee the quality?

A. We will 100% test the goods before delivery. Most welcome of your quality testing team at our warehouse if you want.

Q.4 How long will it take to delivery to my address?

A. The normal delivery time is 30-40 days, depending on which country you are in and the way of Transportation.

Q.5 Do you accept sample order?

A. Yes, sample order can accept.

Q.6 What's package? Can you give me the package according my requirement?

A. We usually packed by standard exported box or carton. And yes we can pack as per your requirement.

.

Похожие товары

Машина для производства локтей креветок

US $2200-$3800

Машина для изготовления декоративных труб

US $26500-$27500

Centrifugal Spun Concrete Pipe Machine

US $1000-$5000