Запчасти для очков запасные петли запчасти в

- Категория: >>>

- Поставщик: Micro,MIM,Japan,Holdings,Inc.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.44 $* | 0.34 $* |

| Aug-15-2025 | 0.36 $* | 0.8 $* |

| Jul-15-2025 | 0.4 $* | 0.15 $* |

| Jun-15-2025 | 0.74 $* | 0.11 $* |

| May-15-2025 | 0.34 $* | 0.13 $* |

| Apr-15-2025 | 0.27 $* | 0.57 $* |

| Mar-15-2025 | 0.35 $* | 0.66 $* |

| Feb-15-2025 | 0.23 $* | 0.50 $* |

| Jan-15-2025 | 0.29 $* | 0.57 $* |

Характеристики

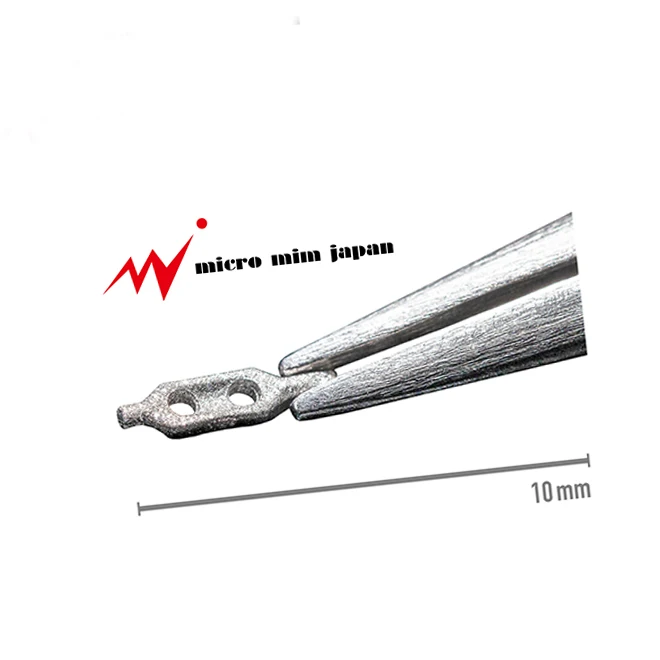

Ti hinge part

Product name | Ti hinge part |

Place of origin | Japan |

Our µ-MIM® technology uses the world-leading fine Ti or Ti alloy powder, thus the tightest tolerance requirement among PM components will be achieved.

Additionally, a high vacuum debinding-sintering furnace is deployed in our mass production, therefore high productivity of small complicated designed parts with good mechanical properties is also realised.

In small complicated parts production, the secondary process is not applicable especially in titanium or titanium alloy components.

Since the fine powder is applied in µ-MIM® production, the surface roughness is low in as-sintered components.

Therefore it is not only possible to realise the stable high-quality serial production of Ti or Ti alloy components but also possible to eliminate the machining oil or metal chip contamination without any post-cleaning process.

Recommend Products

Gear

Medical forceps

Other

Micro MIM Japan Holdings Inc. and its group companies cooperate as a team to cater for various needs of our customers from different parts of the world.

Manufacturing section: Taisei Kogyo Co., Ltd., TAISEI KOGYO(THAILAND) CO., LTD.

Taisei Kogyo Co., Ltd. was established in January 1972 as a plastic injection moulding manufacturer. Aside from improving our technology in the plastic injection moulding, we organised an R&D group in Kyoto Research Park about 25 years ago, to start researching on MIM technology. We utilise our knowledge and experience from the plastic injection moulding and developed original MIM material (binder system and feedstock), which makes it possible to manufacture small and complex shaped MIM components for serial production. Taisei Kogyo Co., Ltd. has obtained ISO13485 in May 2019. TAISEI KOGYO (THAILAND) CO., LTD. was established in August 2011 and started its operation in 2012. We maintain the same production standard as Japanese factory.