Модификация пластмассы TPE SIS SBS SBC SEBS сырье для клеевых

- Категория: TPE >>>

- Поставщик: B.S.M,TRADING,COMPANY,LIMITED

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.12 $* | 0.4 $* |

| Aug-16-2025 | 0.53 $* | 0.55 $* |

| Jul-16-2025 | 0.49 $* | 0.25 $* |

| Jun-16-2025 | 0.78 $* | 0.36 $* |

| May-16-2025 | 0.64 $* | 0.60 $* |

| Apr-16-2025 | 0.93 $* | 0.80 $* |

| Mar-16-2025 | 0.16 $* | 0.51 $* |

| Feb-16-2025 | 0.94 $* | 0.81 $* |

| Jan-16-2025 | 0.85 $* | 0.2 $* |

Характеристики

Our company is one of the leading suppliers of Rubber and Plastic Raw materials mostly in the field of Thermoplastic Elastomers.

SBS

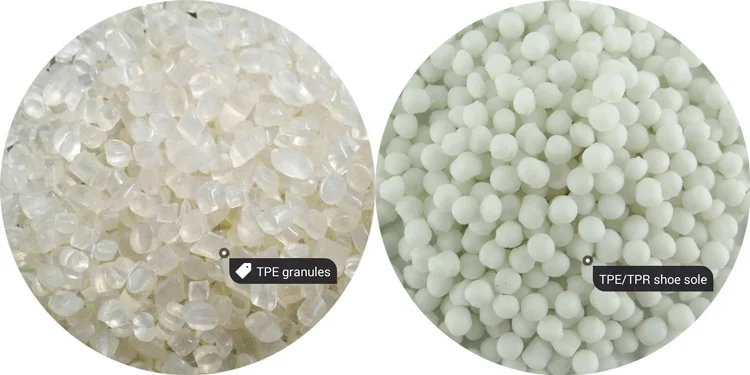

TPE

TPR

TPU

TPE: Thermoplastic Polyurethane Elastomer

TPE (Thermoplastic Polyester Elastomer) is a block copolymer containing polyester hard segments and polyether soft segments. Wherein the polyether soft segment and the non-crystalline polyester form the amorphous phase, the hard segment of the polyester partially crystallizes to form a crystalline micro-zone, which serves as a physical crosslinking point. TPE has the elasticity of rubber and the strength of engineering plastic; the soft segment gives it elasticity so that it behaves like rubber; the hard segment gives it processability making it like plastic; and it has better processability and longer Life; compared with the engineering materials, the same high strength characteristics, and flexibility and dynamic mechanical properties better.

Grade | Dawnprene 13-75A | Dawnprene 13-67A | Dawnprene 13-55A | Dawnprene 6603 | Dawnprene PP-TA20 |

Density | 0.92-0.98 | 0.92-0.96 | 0.92-0.96 | 0.88-0.90 | 0.99-1.1 |

Hardness | 75A±3 | 67A±3 | 55A±3 | 53D±3 | 65D±3 |

Tensile strength | 7.0Mpa | 6.0Mpa | 5.5Mpa | 16.3Mpa | 23.4Mpa |

Elongation at break | 350% | 360% | 400% | 200% | NA |

Tear strength | 46KN/m | 30KN/m | 28KN/m | 95KN/m | NA |

Color | Black | Black | Black | Black | Black |

Flammability | HB | HB | HB | HB | HB |

Form | Round underwater cutting | Round underwater cutting | Round underwater cutting | Round underwater cutting | Uniform granule |

Size | 2-3mm | 2-3mm | 2-3mm | 2-3mm | 2-3mm |

Aging | Excellent | Excellent | Excellent | Excellent | Excellent |

VOC | Low | Low | Low | Low | Low |

Feature | Smooth surface, good elasticity | Smooth surface, good elasticity | Smooth surface, good elasticity | Matt surface, wear resistance | Smooth surface, good adaptability |

Application | GRC,Lip,Base,Belt | GRC,Lip,Base,Belt | GRC, Lip, Belt | Slip Coating | Beltline bone |

Commodity | TPE30C | Quality inspection date | 2018/12/13 | |||

No. | Item | Unit | Standard | Determine scope | Testing result | Test method |

1 | Appearance |

| Visual test | Natural color | Natural color |

|

2 | Hardness | Shore A | ASTM-D2240 | 0~100 | 30C | indoor temperature℃ |

3 | Density | SP.Gr | ASTM-792 | 1.15±0.05 | 1.2 |

|

4 | Solution flow index | g/10min | ASTM-D1238 | 5~20 | 13 | 190℃,2.16kg |

5 | Tensile strength | Mpa | ASTM-D412 | ≥5 | 7.8 | indoor temperature 500mm/min |

6 | Elongation | % | ASTM-D412 | ≥500 | 550 | |

7 | Tear strength | KN/m | ASTM-D624 | ≥20 | 23 | |

Manufacturing technique | ||||||

Barrel temperature | Range ℃ | Typical value ℃ | ||||

Forepart | 150-190 | 170 | ||||

Midpiece | 150-210 | 180 | ||||

Back end | 150-210 | 180 | ||||

Orifice/Die-head | 160-200 | 180 | ||||

Upper limit of processing temperature ℃ | 220 | |||||

Time of drying | Generally there is no need to dry,If the storage environment is humid or the production of products surface requirements higher parts,dry in a hot air oven for 2 to 4 hours | |||||

1.The above data is only for reference. The above data can be adjusted according to different models,molds and product requirements.2.Do not allow the material in the barrel to stay too long too long,Please use PE to clean the machine before stopping it. | ||||||

;l

;l