Ламинированная панель из стекловолокна и эпоксидной смолы для волновой или рефрикционной

- Категория: Electronic Accessories & Supplies >>>

- Поставщик: YUTAKA,CORPORATION

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.75 $* | 0.11 $* |

| Aug-16-2025 | 0.52 $* | 0.94 $* |

| Jul-16-2025 | 0.78 $* | 0.30 $* |

| Jun-16-2025 | 0.64 $* | 0.42 $* |

| May-16-2025 | 0.71 $* | 0.83 $* |

| Apr-16-2025 | 0.39 $* | 0.13 $* |

| Mar-16-2025 | 0.55 $* | 0.44 $* |

| Feb-16-2025 | 0.41 $* | 0.64 $* |

| Jan-16-2025 | 0.76 $* | 0.28 $* |

Характеристики

Products Description

RICOCEL ES-3261A

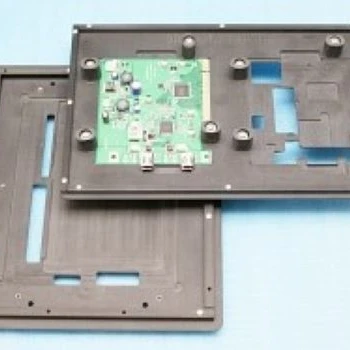

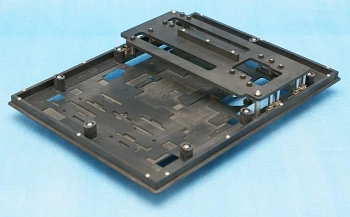

RICOCEL ES-3261A is a high heat resistant glass fiber epoxy resin laminated board for solder pallet.

Component mounting by automatic soldering machine is performed through two kind of work processes.

Generally, it is performed in the order of reflow soldering to wave soldering.

At the wave soldering process, it is necessary to apply solder only to soldering part, with the components mounted by reflow soldering being protected.

RICOCEL is the tool used in the process of wave soldering.

RICOCEL has pockets to protect the pre-mounted components and has through-holes to apply solder only to soldering spots.

Advantages of using solder pallet

Yield : Reduction of defective soldering

Masking process : Setting on pallet

Line width adjustment : Standardized

Thermal stress to electronic components : Small

Size of Blank Material :

Thickness : 3~15mm

Length X Width : 1000X1200 mm 1200X2000 mm

Delivery Form of RICOCEL ES-3261A :

Please choose from among the following three types of the delivery form of RICOCEL ES-3261A.

Finished Product

Finished product after machining such as cutting, grinding and drilling based on your drawing will be supplied.

Board Cut to Specified Dimensions

Board without machining such as drilling, etc. and in the form of simply cutting the material according to the specified dimensions will be supplied.

Blank Material

Blank material without any machining will be supplied.

Component mounting by automatic soldering machine is performed through two kind of work processes.

Generally, it is performed in the order of reflow soldering to wave soldering.

At the wave soldering process, it is necessary to apply solder only to soldering part, with the components mounted by reflow soldering being protected.

RICOCEL is the tool used in the process of wave soldering.

RICOCEL has pockets to protect the pre-mounted components and has through-holes to apply solder only to soldering spots.

Advantages of using solder pallet

Yield : Reduction of defective soldering

Masking process : Setting on pallet

Line width adjustment : Standardized

Thermal stress to electronic components : Small

Size of Blank Material :

Thickness : 3~15mm

Length X Width : 1000X1200 mm 1200X2000 mm

Delivery Form of RICOCEL ES-3261A :

Please choose from among the following three types of the delivery form of RICOCEL ES-3261A.

Finished Product

Finished product after machining such as cutting, grinding and drilling based on your drawing will be supplied.

Board Cut to Specified Dimensions

Board without machining such as drilling, etc. and in the form of simply cutting the material according to the specified dimensions will be supplied.

Blank Material

Blank material without any machining will be supplied.

Our Advantages

1.EXCELLENT DURABILITY

Excellent durability against repetitive soldering of more than 20000-time.

2.EXCELLENT CHEMICAL RESISTANCE

Excellent chemical resistance against soluble flux or pallet cleaner.

3.EXCELLENT MECHANICAL STRENGTH

Excellent mechanical strength for fine machining.

Excellent durability against repetitive soldering of more than 20000-time.

2.EXCELLENT CHEMICAL RESISTANCE

Excellent chemical resistance against soluble flux or pallet cleaner.

3.EXCELLENT MECHANICAL STRENGTH

Excellent mechanical strength for fine machining.

Product Paramenters

Test items | Unit | RICOCEL ES-3261A | |

Color tone | Black | ||

Surface resistance | Ω | 1X107 | |

Specific gravity | 1.95 | ||

Water absorption | % | 0.02 | |

Chemical resistance (Solvent flux) | Good | ||

Loss on heat | 250degrees celsius X 500hr | % | 1.8 |

Bending strength (at RT) | Warp | MPa | 550 |

Fill | MPa | 470 | |

Flexural modulus (at RT) | Fill | GPa | 28 |

Fill | GPa | 26 | |

5% decomposition temp. | TG/DTA | degrees celsius | 430 |

Solder limit | 300degrees celsius | sec | 300< |

CTE (Thickness direction) | α1 | X10-6/K | 45 |

α2 | X10-6/K | 200 | |

Thermal expansion | 50→250degrees celsius | X10-6/K | 7-13 |

Teflon coating | Unnecessary | ||

Machining workability | Good |

Listed values are measured, it is not a guaranteed value.

Company Introduction

We are experts in manufacturing and supplying plastics, ceramics and heat(thermal) insulation/heat(thermal) resistant materials products mainly for machinery parts.

We use machine tools such as Machining Centers and NC lathes to process a variety of plastics, ceramics and heat(thermal) insulation/heat(thermal) resistant materials.

Our product line encompasses a wide range of plastics, ceramics and heat (thermal) insulation materials and we are especially adept at using materials that are difficult to machine including the following ;

1.Heat (thermal) insulation and heat (thermal) resistant materials (rigid heat insulation boards that are generally made of glass fiber, cement and mica as the main raw material)

2.Composite of glass fiber or carbon fiber and plastics (FRP, GFRP and CFRP).

3.Fine ceramics

We use machine tools such as Machining Centers and NC lathes to process a variety of plastics, ceramics and heat(thermal) insulation/heat(thermal) resistant materials.

Our product line encompasses a wide range of plastics, ceramics and heat (thermal) insulation materials and we are especially adept at using materials that are difficult to machine including the following ;

1.Heat (thermal) insulation and heat (thermal) resistant materials (rigid heat insulation boards that are generally made of glass fiber, cement and mica as the main raw material)

2.Composite of glass fiber or carbon fiber and plastics (FRP, GFRP and CFRP).

3.Fine ceramics